Product: ABAQUS/Standard

This example illustrates the capability in ABAQUS to perform fully coupled acoustic-stuctural analyses of a pick-up truck model. This type of analysis has become critically important in the automotive industry and it provides essential benefits toward designing vehicles for ride comfort and quietness. This example uses the pick-up truck model geometry described in “Inertia relief in a pick-up truck,” Section 3.2.1. Only a portion of the pick-up truck is modeled, including the chassis, the cabin, and the air inside the cabin. Structural elements are used to model the cabin and the chassis, and acoustic elements are used to model the air interior. Connector elements are used to connect the various structural parts together. The coupling between the structure and acoustic medium is modeled by applying the surface-based *TIE option. Frequency domain analyses are performed for both regular models (without substructures) and for models using coupled structural-acoustic substructures.

The pick-up truck model (1994 Chevrolet C1500) discussed here is depicted in Figure 8.1.6–1 through Figure 8.1.6–3.

The air is modeled only inside the cabin, and the process of constructing the air mesh in this particular case is worth a brief discussion. Normally, if the solid geometry of the structural part (the cabin) were available, a Boolean subtraction could be performed in ABAQUS/CAE to obtain the solid geometry of the included space (in this case the air inside the cabin). Unfortunately, the solid geometry of the cabin is not available since the structural model is based on a public-domain mesh, as discussed in “Inertia relief in a pick-up truck,” Section 3.2.1. To overcome this issue, the following strategy is adopted. An approximate air geometry is created in ABAQUS/CAE to follow roughly the contour of the cabin interior, including the dashboard, the doors, the cabin floor, the cabin top, the back wall, and the seat. The mesh created from this geometry does not conform exactly to the geometry of the cabin interior. However, by using the ADJUST parameter on the surface-based *TIE constraint that connects the air mesh to the structural parts, the nodes belonging to the air surface will be pushed onto the inside cabin surface or onto the seat surface to conform to the structural mesh (see Figure 8.1.6–2).

The materials used for the cabin and chassis are described in “Inertia relief in a pick-up truck,” Section 3.2.1. The air properties used inside the cabin are: air density of 1.2 kg/m3 and air bulk modulus of 1.39 × 105 Pa, which produce a sound speed of 340 m/s.

Models both with and without damping are constructed. In the models where damping is considered, two forms of damping are modeled, as follows. The *DAMPING option is used to introduce Rayleigh stiffness proportional damping, governed by the parameter ![]() , into the structural materials in the model. For a given value of

, into the structural materials in the model. For a given value of ![]() applied to all materials in the structure (mostly steel), the damping fraction

applied to all materials in the structure (mostly steel), the damping fraction ![]() for a mode

for a mode ![]() with natural circular frequency

with natural circular frequency ![]() is given by the formula

is given by the formula ![]() . The value of

. The value of ![]() in the model is chosen to give approximately 1% critical damping for the modes whose natural frequencies are in the middle of the range of excitation (at about 80 Hz). Surface impedance is also specified on the cabin floor to model the acoustic damping effect of a carpet by using the *SIMPEDANCE and the *IMPEDANCE PROPERTY options. The impedance properties on this surface are chosen such that about 80% of a planar wave incident to this surface in the normal direction would be reflected.

in the model is chosen to give approximately 1% critical damping for the modes whose natural frequencies are in the middle of the range of excitation (at about 80 Hz). Surface impedance is also specified on the cabin floor to model the acoustic damping effect of a carpet by using the *SIMPEDANCE and the *IMPEDANCE PROPERTY options. The impedance properties on this surface are chosen such that about 80% of a planar wave incident to this surface in the normal direction would be reflected.

Four different models are considered.

In the first model only the cabin and the interior air are considered. The structural part of the finite element model is shown in Figure 8.1.6–1 with the doors removed for illustration purposes. The cabin has six connection points with the chassis: two in the front and four under the seat. The outermost four of these connection points are fixed with boundary conditions, and a natural frequency extraction is performed. Several *STEADY STATE DYNAMICS analyses (mode-based, DIRECT, and SUBSPACE PROJECTION) with excitation provided by harmonic point loading at the two hook-up points that have not been constrained follow the *FREQUENCY step. Separate analyses with and without damping are conducted. There are 43,663 structural elements (mostly shells) and about 12,171 acoustic elements in this model for a total of 207,994 degrees of freedom. The average structural element size is about 90 mm, and the average acoustic element size is approximately 325 mm. Considering that at least 5–6 elements are needed per wavelength for accurate representation of the dynamics, the highest excitation frequency for which results can be computed accurately is about 175 Hz.

In the second model the cabin-air model is reduced to a fully coupled structural-acoustic substructure. The four connection points where boundary conditions are applied in the first model are retained using the *RETAINED NODAL DOFS option. In addition, 200 coupled structural-acoustic eigenmodes are extracted and retained using the *RETAINED EIGENMODES option to better represent the dynamics of the substructure in the frequency range of interest. Consequently, the substructure is represented by a total of 224 degrees of freedom to represent the 207,994 degrees of freedom in the first model. The substructure is then used in a separate, one-element natural frequency extraction analysis. The results are recovered from the substructure and compared to the results obtained from the first model.

In the third model both the cabin and the chassis are considered on the structural side (Figure 8.1.6–3), while the air is modeled inside the cabin only. Since no air mesh is used to model the ambient air, this type of model can be used to study the structural path contributions to the noise inside the cabin. In the *STEADY STATE DYNAMICS analyses of this model the excitation is provided by point loads applied to the engine mounts, while the chassis is supported with fixed boundary conditions at its ends. There are 53,897 structural elements in this model, while the number of acoustic elements is the same as in the first model.

Finally, the cabin-chassis model is reduced to two substructures: a fully coupled structural acoustic cabin-air substructure and a structural-only chassis substructure. As in the previous substructure model both the *RETAINED NODAL DOFS and the *RETAINED EIGENMODES options are used to generate the two substructures. The two substructures are represented by 236 and 284 degrees of freedom, respectively. The substructures are then used in a separate, two-element natural frequency extraction analysis; and the results are compared to the results from the third model.

Some of the *STEADY STATE DYNAMICS results for the undamped cabin-air model analyses are shown in Figure 8.1.6–4 and Figure 8.1.6–5. In all analyses 200 sampling points are selected in the frequency range of interest (35–120 Hz) using the TYPE=RANGE option. This frequency range corresponds to engine-induced vibrations in the range of 2100–7200 RPM. Of particular interest in these analyses is the sound pressure level at a location in the vicinity of the driver's ear. The response is shown in Figure 8.1.6–4 and is calculated from the acoustic pressure using the following equation

![]()

Figure 8.1.6–6 shows the noise level for the cabin-air model when damping is considered. Since the mode-based steady-state dynamics analysis would not take into account the forms of damping considered here, only results from the subspace projection and direct analyses are computed. The results compare quite well. Notably, the subspace projection analysis is approximately 20 times faster than the direct analysis. While the sound pressure level is significantly lower in this analysis when compared to the analysis with no damping, the level is still very high. This suggests that the damping considered in this model is still quite low. Impedance-type damping is considered only on the cabin floor; thus, 100% of the acoustic waves would be reflected from the cabin walls, roof, doors, and windows to produce a higher sound pressure level.

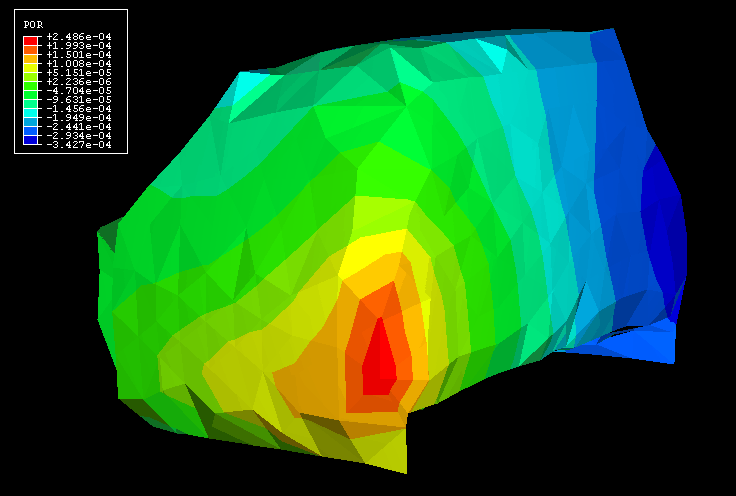

The frequency analysis performed on the cabin-air substructure generates eigenvalues identical to those from the model without substructures. Moreover, the eigenmodes obtained from the regular non-substructure model (Figure 8.1.6–7) and those recovered from the substructure model (Figure 8.1.6–8) compare very well (shown here for the air pressure for the 25th eigenmode).

The frequency response obtained for the cabin-air-chassis model is shown in Figure 8.1.6–9 and Figure 8.1.6–10. Given the size of the model, the direct steady-state dynamics analysis is computationally less efficient and, thus, is not performed. In addition to the natural frequency extraction procedure for the whole structure, a frequency analysis is performed on the equivalent cabin-air-chassis model using two substructures. While the eigenfrequencies are not identical to those obtained from the regular non-substructure model, the differences are quite small for the range of interest, as shown in Figure 8.1.6–11. Once the substructures are generated, the analysis to extract eigenfrequencies from the two-element substructure model is hundreds of times faster than the analysis to extract them from the regular non-substructure model.

The mode-based and the subspace projection steady-state dynamics procedures in ABAQUS demonstrate significant improvements in computational efficiency when compared to the direct steady-state dynamics approach. When damping is small or if it can be well approximated using modal damping coefficients, the mode-based procedures are extremely efficient. When damping is more complex, the subspace projection method also demonstrates significant computational advantage in comparison with the direct-integration approach.

The use of substructures is also demonstrated to produce significant gains in computational efficiency. The reduction of the acoustic volume and of its bounding structure to a substructure has clear advantages. The low-dimensional coupled acoustic-structural substructures are very computationally efficient, and the data for the acoustic response inside the substructure can be recovered when the global analysis is completed.

Mode-based and subspace projection steady-state dynamic analysis of the cabin-air model without damping.

Direct steady-state dynamic analysis of the cabin-air model without damping.

Subspace projection steady-state dynamic analysis of the cabin-air model with damping.

Direct steady-state dynamic analysis of the cabin-air model with damping.

Cabin-air coupled substructure generation for the second model.

Frequency analysis of the cabin-air model using one substructure.

Cabin-air substructure generation analysis for the fourth model.

Chassis substructure generation analysis for the fourth model.

Frequency analysis of the cabin-air-chassis model using two substructures.

All material definitions.

Interior air model.

Coupling definitions for the chassis.

Element definitions for the cabin.

Element set definitions for the cabin.

Node definitions for the cabin.

Node set definitions for the cabin.

Section definitions for the cabin.

Parameter definitions.

Parameter definitions.

All node definitions.

Element definitions for the cabin.

Coupling definitions.

*MPC definitions for the cabin.

Element definitions for the seat.

Coupling definitions for the seat.

Connector definitions for the seat.

Element definitions for the left door.

Coupling definitions for the left door.

*MPC definitions for the left door.

Connector definitions for the left door.

Element definitions for the right door.

Coupling definitions for the right door.

*MPC definitions for the right door.

Element definitions for the chassis.

Figure 8.1.6–6 Sound pressure level at the ear position for the cabin-air model when damping is considered.

Figure 8.1.6–8 Air pressure for the 25th eigenmode (35.131 Hz) from the cabin-air substructure model.