Products: ABAQUS/Explicit ABAQUS/CAE

Connector damage behavior:

can be specified in any connectors with available components of relative motion;

can be used to degrade the elastic, elastic-plastic, or rigid plastic response in connector elements;

can use a force-based, motion-based, or plastic motion-based damage initiation criterion upon which response degradation may be triggered;

can use either a (plastic) motion-based or an energy-based damage evolution law to degrade the force response in the connector;

can be defined in terms of several competing damage mechanisms;

can be used only as an indicator of proximity to the damage initiation point without degrading the connector response; and

can be used only in ABAQUS/Explicit.

If relative forces or motions in a connection exceed critical values, the connector starts undergoing irreversible damage (degradation). Upon additional loading there is further evolution of damage leading to eventual failure. If damage has occurred, the force response in the connector component i will change according to the following general form:

![]()

To define a connector damage mechanism in ABAQUS/Explicit, you specify the following:

a criterion for damage initiation; and

a damage evolution law that specifies how the damage variable ![]() evolves (optional).

evolves (optional).

ABAQUS/Explicit offers the flexibility of specifying multiple competing damage mechanisms (pairs of damage initiation criteria and damage evolution laws). If the damage evolution law is not specified for a particular damage mechanism, the associated damage variable is held fixed at 0.0 and the damage mechanism does not contribute to degrading the response in the connector. Each damage initiation criterion has an output variable associated with it to indicate the proximity to damage initiation and whether the criterion is met. A value less than 1.0 indicates that the criterion is not met. The closer the value is to 1.0, the more imminent damage initiation is. A value of 1.0 indicates that the initiation criterion has been met.

The degradation process in connectors initiates when forces or relative motions in the connector satisfy certain criteria. Three different criteria types can be used to trigger damage in connectors: criteria based on force, plastic motion, or constitutive motion. Connector damage initiation criteria for the available components of relative motion can be specified for each component independently (uncoupled). Alternatively, connector damage initiation criteria that couple all or some of the available components of relative motion in the connector can be defined.

The damage initiation criterion can depend on temperature and field variables. See “Input syntax rules,” Section 1.2.1, for further information about defining data as functions of temperature and field variables.

By default, the damage initiation criterion is specified in terms of forces/moments in the connector. Elastic or rigid connector behavior must be defined for the components involved in the initiation. You provide the lower (compression) limit, ![]() , and the upper (tension) limit,

, and the upper (tension) limit, ![]() , for the force/moment damage initiation values. If the force is outside the range specified by the two limit values, damage is initiated. The output variable CDIF can be used to monitor the proximity to the damage initiation point.

, for the force/moment damage initiation values. If the force is outside the range specified by the two limit values, damage is initiated. The output variable CDIF can be used to monitor the proximity to the damage initiation point.

For an uncoupled force-based damage initiation criterion, the connector force in the specified component is compared to the specified limit values. Damage is initiated when the force in the specified component ![]() ,

, ![]() , is for the first time outside the range (

, is for the first time outside the range (![]() or

or ![]() ).

).

| Input File Usage: | *CONNECTOR DAMAGE INITIATION, COMPONENT=component number, CRITERION=FORCE (default), DEPENDENCIES=n |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

For a coupled force-based damage initiation criterion, a connector potential, ![]() , must be specified to define an equivalent force magnitude (scalar). The equivalent force magnitude is compared to the specified limit values to assess damage initiation. Damage is initiated when the equivalent force magnitude,

, must be specified to define an equivalent force magnitude (scalar). The equivalent force magnitude is compared to the specified limit values to assess damage initiation. Damage is initiated when the equivalent force magnitude, ![]() , is for the first time outside the range (

, is for the first time outside the range (![]() or

or ![]() ).

).

| Input File Usage: | Use the following options: |

*CONNECTOR DAMAGE INITIATION, CRITERION=FORCE (default), DEPENDENCIES=n *CONNECTOR POTENTIAL |

| ABAQUS/CAE Usage: | Coupled force-based damage initiation is not supported in ABAQUS/CAE. |

The damage initiation criterion can be specified in terms of an equivalent relative plastic motion in the connector. You provide the relative equivalent plastic displacement/rotation at which damage will be initiated as a function of the relative equivalent plastic rate. The output variable CDIP can be used to monitor the proximity to the damage initiation point.

For an uncoupled elastic-plastic or rigid plastic damage initiation criterion, uncoupled connector plasticity in the specified component of relative motion must be defined (see “Connector plastic behavior,” Section 17.2.6). When the equivalent relative plastic motion as defined by the associated plasticity definition is greater than the specified limit value for the first time, damage is initiated.

| Input File Usage: | Use the following options: |

*CONNECTOR DAMAGE INITIATION, COMPONENT=component number, CRITERION=PLASTIC MOTION, DEPENDENCIES=n *CONNECTOR PLASTICITY, COMPONENT=component number or *CONNECTOR PLASTICITY |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

For a coupled elastic-plastic or rigid plastic damage initiation criterion, coupled connector plasticity must be defined. The connector potential used in the coupled connector plasticity function defines an equivalent relative plastic motion. This equivalent relative plastic motion is compared to the specified limit values to assess damage initiation. The equivalent relative plastic motion at which damage is initiated can be a function of the mode-mix ratio ![]() (see “Connector plastic behavior,” Section 17.2.6).

(see “Connector plastic behavior,” Section 17.2.6).

| Input File Usage: | Use the following options: |

*CONNECTOR DAMAGE INITIATION, CRITERION=PLASTIC MOTION, DEPENDENCIES=n *CONNECTOR PLASTICITY *CONNECTOR POTENTIAL |

| ABAQUS/CAE Usage: | Coupled plastic damage initiation is not supported in ABAQUS/CAE. |

The damage initiation criterion can be specified in terms of relative constitutive displacements/rotations in the connector. You provide the lower (compression) limit, ![]() , and the upper (tension) limit,

, and the upper (tension) limit, ![]() , for the constitutive displacement/rotation damage initiation values. If the motion is outside the range specified by the two limit values, damage is initiated. The output variable CDIM can be used to monitor the proximity to the damage initiation point.

, for the constitutive displacement/rotation damage initiation values. If the motion is outside the range specified by the two limit values, damage is initiated. The output variable CDIM can be used to monitor the proximity to the damage initiation point.

For an uncoupled motion-based damage initiation criterion, the connector relative constitutive motion in the specified component is compared to the specified limit values. Damage is initiated when the relative constitutive displacement/rotation in the specified component ![]() ,

, ![]() , is for the first time outside the range (

, is for the first time outside the range (![]() or

or ![]() ).

).

| Input File Usage: | *CONNECTOR DAMAGE INITIATION, COMPONENT=component number, CRITERION=MOTION, DEPENDENCIES=n |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

For a coupled motion-based damage initiation criterion, a connector potential, ![]() , must be specified to define an equivalent motion magnitude (scalar), where

, must be specified to define an equivalent motion magnitude (scalar), where ![]() is the collection of all available components of relative motion in the connector. The equivalent motion magnitude is compared to the specified limit values to assess damage initiation. Damage is initiated when the equivalent motion magnitude,

is the collection of all available components of relative motion in the connector. The equivalent motion magnitude is compared to the specified limit values to assess damage initiation. Damage is initiated when the equivalent motion magnitude, ![]() , is for the first time outside the range (

, is for the first time outside the range (![]() or

or ![]() ).

).

| Input File Usage: | Use the following options: |

*CONNECTOR DAMAGE INITIATION, CRITERION=MOTION, DEPENDENCIES=n *CONNECTOR POTENTIAL |

| ABAQUS/CAE Usage: | Coupled constitutive motion-based damage initiation is not supported in ABAQUS/CAE. |

Connector damage evolution specifies the evolution law for the damage variable. Upon evolution, the connector response will be degraded. The evolution of damage can be based on an energy dissipation criterion or on relative (plastic) motions. In the motion-based criteria the damage variable, ![]() , can be defined as a linear, exponential, or tabular function of relative motions.

, can be defined as a linear, exponential, or tabular function of relative motions.

The damage evolution law can depend on temperature and field variables. See “Input syntax rules,” Section 1.2.1, for further information about defining data as functions of temperature and field variables.

By default (i.e., the affected components are not specified explicitly), only the elastic/rigid or elastic/rigid-plastic response in the connector will be damaged. The response due to friction, damping, and stop/lock behavior will not be degraded. For an uncoupled connector damage mechanism (uncoupled damage initiation criterion), only the specified component of relative motion will undergo damage. For coupled connector damage initiation, the components that will be degraded by default are chosen as follows:

If a force-based or constitutive motion-based damage initiation criterion is used, the intrinsic available components (1 through 6) that ultimately contribute to the connector potential for damage initiation will be affected.

If a plastic motion-based damage initiation criterion is used, the intrinsic available components that ultimately contribute to the connector potential used in the coupled plasticity definition will be affected.

Alternatively, you can specify the available components of relative motion that will be affected by the damage evolution law directly. In this case the entire connector response (elasto/rigid-plastic, friction, damping, constraint forces and moments, etc.) in the affected components will be damaged.

| Input File Usage: | *CONNECTOR DAMAGE EVOLUTION, AFFECTED COMPONENTS |

| The first data line identifies the component numbers that will be damaged, and the additional data for the connector damage evolution definition begins on the second data line. |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

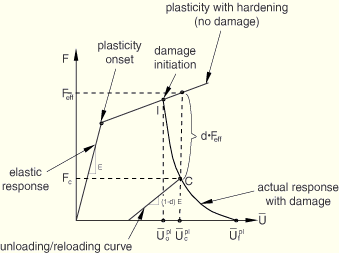

The linear form of the damage evolution law is illustrated here in the context of linear elasticity, although it can be used in any situation. Assume that the connector response is linear elastic and that after damage initiation a linear damage evolution is desired, as illustrated in Figure 17.2.7–1.

If damage were not specified, the response would be linear elastic (a straight line passing through the origin). Assume that damage has initiated at point I as triggered by a force-based or motion-based criterion, for example; the corresponding constitutive motion at this point isThe linear damage evolution law defines a truly linear damaged force response only in the case of linear elastic or rigid behavior with optional perfect plasticity. If nonlinear elasticity or plasticity with hardening are defined for the damaged components, an approximate linear damaged response is observed.

If an uncoupled damage initiation criterion is used in component ![]() , you specify the difference between the constitutive relative motion at ultimate failure,

, you specify the difference between the constitutive relative motion at ultimate failure, ![]() , and the constitutive relative motion at damage initiation,

, and the constitutive relative motion at damage initiation, ![]() , in the specified component (

, in the specified component (![]() ).

).

If a coupled damage initiation criterion is used, an equivalent constitutive relative motion, ![]() , must be defined for damage evolution purposes. A connector potential definition is used to define

, must be defined for damage evolution purposes. A connector potential definition is used to define ![]() . You specify the difference between the equivalent motion at ultimate failure,

. You specify the difference between the equivalent motion at ultimate failure, ![]() , and the equivalent motion at damage initiation,

, and the equivalent motion at damage initiation, ![]() (

(![]() ).

).

| Input File Usage: | Use the following options to define a linear evolution law for an uncoupled initiation criterion: |

*CONNECTOR DAMAGE INITIATION, COMPONENT=component number, CRITERION=FORCE or MOTION *CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=LINEAR Use the following options to define a linear evolution law for a coupled initiation criterion: *CONNECTOR DAMAGE INITIATION, CRITERION=FORCE or MOTION *CONNECTOR POTENTIAL *CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=LINEAR *CONNECTOR POTENTIAL The second *CONNECTOR POTENTIAL option defines |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

| Coupled damage behavior is not supported in ABAQUS/CAE. |

You can specify the difference between the associated equivalent plastic relative motion at ultimate failure, ![]() , and the associated equivalent plastic relative motion at damage initiation,

, and the associated equivalent plastic relative motion at damage initiation, ![]() (

(![]() ), as a function of the mode-mix ratio,

), as a function of the mode-mix ratio, ![]() , defined in “Connector plastic behavior,” Section 17.2.6. The equivalent plastic relative motions are calculated from the associated plasticity definition (either coupled or uncoupled).

, defined in “Connector plastic behavior,” Section 17.2.6. The equivalent plastic relative motions are calculated from the associated plasticity definition (either coupled or uncoupled).

| Input File Usage: | Use the following options: |

*CONNECTOR DAMAGE INITIATION, CRITERION=PLASTIC MOTION *CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=LINEAR |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

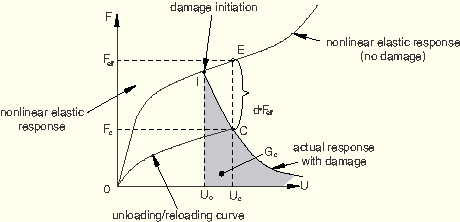

The exponential damage evolution law is illustrated in the context of a linear elastic-plastic response with hardening, although it can be used in any situation. The force response in a particular connector component is shown in Figure 17.2.7–2.

Figure 17.2.7–2 Exponential damage evolution law for linear elastic-plastic connector behavior with hardening.

The damaged response will appear to be truly exponential only if either linear elasticity or perfect plasticity is used. An approximate exponential degradation is obtained if plasticity with hardening is present.

You specify the difference between the relative motions at ultimate failure and at damage initiation and the exponential coefficient ![]() . The difference between the relative motions is interpreted in the same way as described in “Defining a motion-based linear damage evolution law,” as follows:

. The difference between the relative motions is interpreted in the same way as described in “Defining a motion-based linear damage evolution law,” as follows:

If an uncoupled force-based or constitutive motion-based damage initiation criterion is used, the difference between the relative motions at ultimate failure and at damage initiation in the specified component ![]() ,

, ![]() , is specified.

, is specified.

If a coupled force-based or constitutive motion-based damage initiation criterion is used, an equivalent relative motion is defined using a connector potential (![]() ). The difference between the relative motions at ultimate failure and at damage initiation,

). The difference between the relative motions at ultimate failure and at damage initiation, ![]() , is specified.

, is specified.

If a plastic motion-based damage initiation criterion is used, the difference between the equivalent relative plastic motions at ultimate failure and at damage initiation, ![]() , is specified. The equivalent plastic relative motion is calculated from the associated plasticity definition. The data can also be functions of the mode-mix ratio

, is specified. The equivalent plastic relative motion is calculated from the associated plasticity definition. The data can also be functions of the mode-mix ratio ![]() .

.

| Input File Usage: | *CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=EXPONENTIAL |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

You can also specify the damage variable directly as a tabular function of the differences between the relative motions at ultimate failure and the relative motions at damage initiation. The differences between the relative motions are interpreted in the same way as described in “Defining a motion-based linear damage evolution law,” as follows:

If an uncoupled force-based or constitutive motion-based damage initiation criterion is used, the differences between the constitutive relative motions at ultimate failure and at damage initiation in the specified component ![]() ,

, ![]() , are used to define the tabular data.

, are used to define the tabular data.

If a coupled force-based or constitutive motion-based damage initiation criterion is used, an equivalent relative motion is defined using a connector potential (![]() ). The differences between the relative motions at ultimate failure and at damage initiation,

). The differences between the relative motions at ultimate failure and at damage initiation, ![]() , are used to define the tabular data.

, are used to define the tabular data.

If a plastic motion-based damage initiation criterion is used, the differences between the equivalent relative plastic motions at ultimate failure and at damage initiation, ![]() , are used. The equivalent plastic relative motion is calculated from the associated plasticity definition. The tabular data can also be functions of the mode-mix ratio

, are used. The equivalent plastic relative motion is calculated from the associated plasticity definition. The tabular data can also be functions of the mode-mix ratio ![]() .

.

| Input File Usage: | *CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=TABULAR, DEPENDENCIES=n |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

This damage evolution law is illustrated in the context of nonlinear elasticity, as shown in Figure 17.2.7–3.

Figure 17.2.7–3 Post-damage initiation dissipation energy evolution law for nonlinear elastic connector behavior.

Instantaneous failure can be specified upon initiation if ![]() is specified as 0.0. In all other cases ultimate failure (

is specified as 0.0. In all other cases ultimate failure (![]() = 1) would occur (in theory) at infinite motion since an exponential-like response that asymptotically goes to zero is generated. ABAQUS/Explicit will set

= 1) would occur (in theory) at infinite motion since an exponential-like response that asymptotically goes to zero is generated. ABAQUS/Explicit will set ![]() = 1 when the damage dissipated energy reaches 0.99

= 1 when the damage dissipated energy reaches 0.99![]() .

.

You specify the post-initiation damage dissipated energy at ultimate failure, ![]() . If a plastic motion-based initiation criterion is used,

. If a plastic motion-based initiation criterion is used, ![]() can be specified as a function of the mode-mix ratio

can be specified as a function of the mode-mix ratio ![]() .

.

| Input File Usage: | *CONNECTOR DAMAGE EVOLUTION, TYPE=ENERGY, DEPENDENCIES=n |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

At most three uncoupled damage mechanisms (pairs of connector damage initiation criteria and connector damage evolution laws) can be defined for each available component of relative motion, one for each type of initiation criterion (force, motion, and plastic motion). In addition, three coupled damage mechanisms can be defined (one for each type of initiation criterion). Coupled and uncoupled damage definitions can be combined; only one overall damage variable per component will be used to damage the response in a particular available component of relative motion. Only the overall damage will be output.

When several damage mechanisms are defined for the same connector behavior, you can specify the contribution of each damage mechanism to the overall damage effect for a particular component of relative motion. By default, the damage value associated with a particular mechanism will be compared to the damage values from any other damage mechanisms defined for the connector behavior, and only the maximum value will be considered for the overall damage. Alternatively, you can specify that the damage values for the mechanisms associated with the connector behavior should be combined in a multiplicative fashion to obtain the overall damage. See the last example below for an illustration.

| Input File Usage: | Use the following option to specify that only the maximum damage value associated with a particular connector behavior should contribute to the overall damage effect: |

*CONNECTOR DAMAGE EVOLUTION, DEGRADATION=MAXIMUM Use the following option to specify that all the damage values associated with a particular connector behavior should contribute in a multiplicative way to the overall damage effect: *CONNECTOR DAMAGE EVOLUTION, DEGRADATION=MULTIPLICATIVE |

| ABAQUS/CAE Usage: | Interaction module: connector property editor: Add |

The examples that follow illustrate several methods for defining damage mechanisms.

The following input could be used to define a simple uncoupled damage mechanism:

*CONNECTOR ELASTICITY, COMPONENT=1 *CONNECTOR DAMAGE INITIATION, COMPONENT=1, CRITERION=FORCE force_compress, force_tens *CONNECTOR DAMAGE EVOLUTION, TYPE=ENERGY 0.0Damage will initiate when the elastic force in component 1 is either smaller than force_compress or larger than force_tens. Only the elastic response in component 1 will be damaged. Since the dissipated energy specified for damage evolution is 0.0, the damage evolves catastrophically instantaneously after it has initiated.

Referring to the spot weld in Figure 17.2.7–4 for which coupled plasticity is defined in “Connector plastic behavior,” Section 17.2.6, a plastic motion-based damage initiation and evolution with dependencies on the mode-mix ratio can be specified as follows:

*PARAMETERThe equivalent plastic relative motion on the data lines is defined by the associated coupled plasticity definition illustrated in “Connector plastic behavior,” Section 17.2.6. For the damage evolution the post-damage-initiation equivalent plastic relative motion should be specified. The second column in all the data lines represents the mode-mix ratios as defined in “Connector plastic behavior,” Section 17.2.6. In this particular case the mode-mix ratio is=0.25

=0.35

=0.45

=0.75

=0.78

=0.82

=0.85 *CONNECTOR DAMAGE INITIATION, CRITERION=PLASTIC MOTION

, 0.0

, 0.5

, 1.0 *CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=LINEAR

, 0.0

, 0.3

, 0.5

, 1.0

Referring to the spot weld in Figure 17.2.7–4 and using the derived components normal and shear defined in “Defining derived components for connector elements” in “Connector functions for coupled behavior,” Section 17.2.4, an alternative way to define damage in the spot weld is to use:

*PARAMETERDamage will be initiated when the force magnitude defined by the first connector potential definition exceeds the specified value of 1.0. The scale factors=2

=0.85

=120.0

=115.0 *CONNECTOR DAMAGE INITIATION, CRITERION=FORCE , 1.0 *CONNECTOR POTENTIAL normal,

shear,

**

*CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=EXPONENTIAL

,

*CONNECTOR POTENTIAL 1 2 3 **

This example illustrates how to specify the contributions of multiple damage mechanisms to the overall damage effect and the components of relative motion affected by the damage evolution law. Most of the data line entries or parameters are not given for conciseness.

** first damage mechanism: force-based damage initiation ** damage variableFour damage mechanisms (connector damage initiation/connector damage evolution pairs) are specified: three uncoupled and one coupled. The first line of each damage evolution definition establishes the components that will be damaged by the mechanism. The overall damage in a particular component is determined by contributions from all the mechanisms that affect that component. For example, the overall damage in component 1,*CONNECTOR DAMAGE INITIATION, COMPONENT=4, CRITERION=FORCE *CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=EXPONENTIAL, DEGRADATION=MAXIMUM, AFFECTED COMPONENTS 4, 6 ** ** second damage mechanism: motion-based damage initiation ** damage variable

*CONNECTOR DAMAGE INITIATION, COMPONENT=4, CRITERION=MOTION *CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=LINEAR, DEGRADATION=MULTIPLICATIVE, AFFECTED COMPONENTS 1, 2, 6 ** ** third damage mechanism: plastic motion-based damage initiation ** damage variable

*CONNECTOR DAMAGE INITIATION, COMPONENT=4, CRITERION=PLASTIC MOTION *CONNECTOR DAMAGE EVOLUTION, TYPE=MOTION, SOFTENING=TABULAR, DEGRADATION=MULTIPLICATIVE, AFFECTED COMPONENTS 1, 2 ** ** fourth damage mechanism: coupled force-based damage initiation ** damage variable

*CONNECTOR DAMAGE INITIATION, CRITERION=FORCE *CONNECTOR POTENTIAL ** using components 1, 2, 3, 4, 5, 6 *CONNECTOR DAMAGE EVOLUTION, TYPE=ENERGY, DEGRADATION=MAXIMUM, AFFECTED COMPONENTS 1, 3, 4, 6

![]()

For example, assume that at a particular time ![]() ,

, ![]() =0.5,

=0.5, ![]() =0.3, and

=0.3, and ![]() =0.2 and at time

=0.2 and at time ![]() ,

, ![]() =0.6 (the only one increasing) while

=0.6 (the only one increasing) while ![]() and

and ![]() stay the same. The overall damage variable gets closer to the ultimate damage value faster when all three damage mechanisms are used than if we use only the

stay the same. The overall damage variable gets closer to the ultimate damage value faster when all three damage mechanisms are used than if we use only the ![]() mechanism:

mechanism:

![]()

![]()

![]() , where

, where ![]() refers to the

refers to the ![]() available component of relative motion. The overall damage variables for the other components are determined as follows (based on the specified affected components for each damage evolution law):

available component of relative motion. The overall damage variables for the other components are determined as follows (based on the specified affected components for each damage evolution law):

The ABAQUS output variables available for connectors are listed in “ABAQUS/Standard output variable identifiers,” Section 4.2.1, and “ABAQUS/Explicit output variable identifiers,” Section 4.2.2. The following variables are of particular interest when damage is defined in connectors:

CDMG | Connector overall damage variable. |

CDIF | Force-based connector damage initiation variable. In addition to the usual six components associated with connector output variables, CDIF includes the scalar CDIFC, which is the damage initiation criterion value associated with a coupled force-based damage initiation criterion. |

CDIM | Motion-based connector damage initiation variable. CDIM includes the scalar CDIMC, which is the damage initiation criterion value associated with a coupled motion-based damage initiation criterion. |

CDIP | Plastic motion-based connector damage initiation variable. CDIP includes the scalar CDIPC, which is the damage initiation criterion value associated with a coupled plastic motion-based damage initiation criterion. |