Products: ABAQUS/Standard ABAQUS/Explicit ABAQUS/CAE

The crushable foam plasticity models:

are intended for the analysis of crushable foams that are typically used as energy absorption structures;

can be used to model crushable materials other than foams (such as balsa wood);

are used to model the enhanced ability of a foam material to deform in compression due to cell wall buckling processes (it is assumed that the resulting deformation is not recoverable instantaneously and can, thus, be idealized as being plastic for short duration events);

can be used to model the difference between a foam material's compressive strength and its much smaller tensile bearing capacity resulting from cell wall breakage in tension;

must be used in conjunction with the linear elastic material model (“Linear elastic behavior,” Section 17.2.1);

can be used when rate-dependent effects are important; and

are intended to simulate material response under essentially monotonic loading.

The elastic part of the response is specified as described in “Linear elastic behavior,” Section 17.2.1. Only linear isotropic elasticity can be used.

For the plastic part of the behavior, the yield surface is a Mises circle in the deviatoric stress plane and an ellipse in the meridional (p–q) stress plane. The only model available in ABAQUS/Standard and the default model in ABAQUS/Explicit is the volumetric hardening model, where the point on the yield ellipse in the meridional plane that represents hydrostatic tension loading is fixed and the evolution of the yield surface is driven by the volumetric compacting plastic strain. In ABAQUS/Explicit an isotropic hardening model is also available, where the yield ellipse is centered at the origin in the p–q stress plane and evolves in a geometrically self-similar manner. This phenomenological isotropic model was originally developed for metallic foams by Deshpande and Fleck (2000).

The hardening curve must describe the uniaxial compression yield stress as a function of the corresponding plastic strain. In defining this dependence at finite strains, “true” (Cauchy) stress and logarithmic strain values should be given. Both models predict similar behavior for compression-dominated loading. However, for hydrostatic tension loading the volumetric hardening model assumes a perfectly plastic behavior, while the isotropic hardening model predicts the same behavior in both hydrostatic tension and hydrostatic compression.

The crushable foam model with volumetric hardening uses a yield surface with an elliptical dependence of deviatoric stress on pressure stress. It assumes that the evolution of the yield surface is controlled by the volumetric compacting plastic strain experienced by the material. Volumetric hardening is the only model available in an ABAQUS/Standard analysis.

The yield surface for the volumetric hardening model is defined as

![]()

![]()

is the pressure stress,

![]()

is the Mises stress,

![]()

is the deviatoric stress,

A

is the size of the (horizontal) p-axis of the yield ellipse,

![]()

is the size of the (vertical) q-axis of the yield ellipse,

![]()

is the shape factor of the yield ellipse that defines the relative magnitude of the axes,

![]()

is the center of the yield ellipse on the p-axis,

![]()

is the strength of the material in hydrostatic tension, and

![]()

is the yield stress in hydrostatic compression (![]() is always positive).

is always positive).

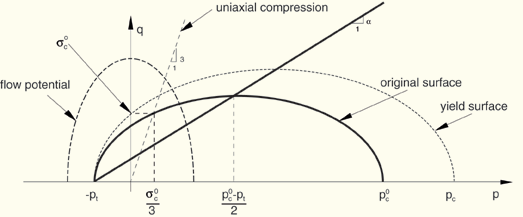

Figure 18.3.5–1 Crushable foam model with volumetric hardening: yield surface and flow potential in the p–q stress plane.

The yield surface evolves in a self-similar fashion (constant ![]() ); and the shape factor can be computed using the initial yield stress in uniaxial compression,

); and the shape factor can be computed using the initial yield stress in uniaxial compression, ![]() , the initial yield stress in hydrostatic compression,

, the initial yield stress in hydrostatic compression, ![]() (the initial value of

(the initial value of ![]() ), and the yield strength in hydrostatic tension,

), and the yield strength in hydrostatic tension, ![]() :

:

![]()

To define the shape of the yield surface, you provide the values of k and ![]() . If desired, these variables can be defined as a tabular function of temperature and other predefined field variables.

. If desired, these variables can be defined as a tabular function of temperature and other predefined field variables.

| Input File Usage: | *CRUSHABLE FOAM, HARDENING=VOLUMETRIC |

| ABAQUS/CAE Usage: | Property module: material editor: Mechanical |

To use this model, one needs to know the initial yield stress in uniaxial compression, ![]() ; the initial yield stress in hydrostatic compression,

; the initial yield stress in hydrostatic compression, ![]() ; and the yield strength in hydrostatic tension,

; and the yield strength in hydrostatic tension, ![]() . Since foam materials are rarely tested in tension, it is usually necessary to guess the magnitude of the strength of the foam in hydrostatic tension,

. Since foam materials are rarely tested in tension, it is usually necessary to guess the magnitude of the strength of the foam in hydrostatic tension, ![]() . The choice of tensile strength should not have a strong effect on the numerical results unless the foam is stressed in hydrostatic tension. A common approximation is to set

. The choice of tensile strength should not have a strong effect on the numerical results unless the foam is stressed in hydrostatic tension. A common approximation is to set ![]() equal to 5% to 10% of the initial yield stress in hydrostatic compression

equal to 5% to 10% of the initial yield stress in hydrostatic compression ![]() ; thus,

; thus, ![]() = 0.05 to 0.10.

= 0.05 to 0.10.

The plastic strain rate for the volumetric hardening model is assumed to be

![]()

![]()

![]()

![]()

The nonassociated plastic flow rule makes the material stiffness matrix unsymmetric; therefore, the unsymmetric matrix storage and solution scheme should be used in ABAQUS/Standard (see “Procedures: overview,” Section 6.1.1). Usage of this scheme is especially important when large regions of the model are expected to flow plastically.

The yield surface intersects the p-axis at ![]() and

and ![]() . We assume that

. We assume that ![]() remains fixed throughout any plastic deformation process. By contrast, the compressive strength,

remains fixed throughout any plastic deformation process. By contrast, the compressive strength, ![]() , evolves as a result of compaction (increase in density) or dilation (reduction in density) of the material. The evolution of the yield surface can be expressed through the evolution of the yield surface size on the hydrostatic stress axis,

, evolves as a result of compaction (increase in density) or dilation (reduction in density) of the material. The evolution of the yield surface can be expressed through the evolution of the yield surface size on the hydrostatic stress axis, ![]() , as a function of the value of volumetric compacting plastic strain,

, as a function of the value of volumetric compacting plastic strain, ![]() . With

. With ![]() constant, this relation can be obtained from user-provided uniaxial compression test data using

constant, this relation can be obtained from user-provided uniaxial compression test data using

| Input File Usage: | *CRUSHABLE FOAM HARDENING |

| ABAQUS/CAE Usage: | Property module: material editor: Mechanical |

As strain rates increase, many materials show an increase in the yield stress. For many crushable foam materials this increase in yield stress becomes important when the strain rates are in the range of 0.1–1 per second and can be very important if the strain rates are in the range of 10–100 per second, as commonly occurs in high-energy dynamic events.

Two methods for specifying strain-rate-dependent material behavior are available in ABAQUS as discussed below. Both methods assume that the shapes of the hardening curves at different strain rates are similar, and either can be used in static or dynamic procedures. When rate dependence is included, the static stress-strain hardening behavior must be specified for the crushable foam as described above.

You can specify a Cowper-Symonds overstress power law that defines strain rate dependence. This law has the form

![]()

![]()

![]()

| Input File Usage: | Use both of the following options: |

*CRUSHABLE FOAM HARDENING *RATE DEPENDENT, TYPE=POWER LAW |

| ABAQUS/CAE Usage: | Property module: material editor: Mechanical |

The power-law rate dependency can be rewritten in the following form

![]()

Compute R using the uniaxial compression yield stress ratio, r.

Convert the rate of the axial plastic strain, ![]() , to the corresponding equivalent plastic strain rate,

, to the corresponding equivalent plastic strain rate, ![]() .

.

Plot ![]() versus

versus ![]() . If the curve can be approximated by a straight line such as that shown in Figure 18.3.5–2, the overstress power law is suitable. The slope of the line is

. If the curve can be approximated by a straight line such as that shown in Figure 18.3.5–2, the overstress power law is suitable. The slope of the line is ![]() , and the intercept of the

, and the intercept of the ![]() axis is

axis is ![]() .

.

Rate-dependent behavior can alternatively be specified by giving a table of the ratio ![]() as a function of the absolute value of the rate of the axial plastic strain and, optionally, temperature and predefined field variables.

as a function of the absolute value of the rate of the axial plastic strain and, optionally, temperature and predefined field variables.

| Input File Usage: | Use both of the following options: |

*CRUSHABLE FOAM HARDENING *RATE DEPENDENT, TYPE=YIELD RATIO |

| ABAQUS/CAE Usage: | Property module: material editor: Mechanical |

There are cases when we need to study the behavior of a material that has already been subjected to some hardening. For such cases ABAQUS allows you to prescribe initial conditions for the volumetric compacting plastic strain, ![]() (see “Defining initial values of state variables for plastic hardening” in “Initial conditions,” Section 27.2.1).

(see “Defining initial values of state variables for plastic hardening” in “Initial conditions,” Section 27.2.1).

| Input File Usage: | *INITIAL CONDITIONS, TYPE=HARDENING |

| ABAQUS/CAE Usage: | Initial hardening conditions are not supported in ABAQUS/CAE. |

The isotropic hardening model available in ABAQUS/Explicit uses a yield surface that is an ellipse centered at the origin in the p–q stress plane. The yield surface evolves in a self-similar manner, and the evolution is governed by the equivalent plastic strain (to be defined later).

The yield surface for the isotropic hardening model is defined as

![]()

![]()

is the pressure stress,

![]()

is the Mises stress,

![]()

is the deviatoric stress,

![]()

is the size of the (vertical) q-axis of the yield ellipse,

![]()

is the shape factor of the yield ellipse that defines the relative magnitude of the axes,

![]()

is the yield stress in hydrostatic compression, and

![]()

is the absolute value of the yield stress in uniaxial compression.

![]()

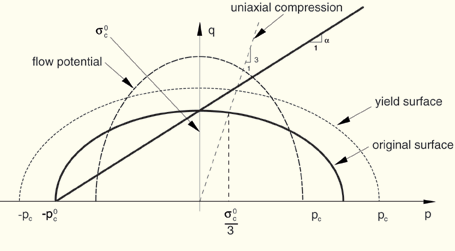

Figure 18.3.5–3 Crushable foam model with isotropic hardening: yield surface and flow potential in the p–q stress plane.

To define the shape of the yield ellipse, you provide the value of k. For a valid yield surface the strength ratio must be such that ![]() . The particular case of

. The particular case of ![]() corresponds to the Mises plasticity. In general, the initial yield strengths in uniaxial compression and in hydrostatic compression,

corresponds to the Mises plasticity. In general, the initial yield strengths in uniaxial compression and in hydrostatic compression, ![]() and

and ![]() , can be used to calculate the value of k. However, in many practical cases the stress versus strain response curves of crushable foam materials do not show clear yielding points, and the initial yield stress values cannot be determined exactly. Many of these response curves have a horizontal plateau—the yield stress is nearly a constant for a significantly large range of plastic strain values. If you have data from both uniaxial compression and hydrostatic compression, the plateau values of the two experimental curves can be used to calculate the ratio of k.

, can be used to calculate the value of k. However, in many practical cases the stress versus strain response curves of crushable foam materials do not show clear yielding points, and the initial yield stress values cannot be determined exactly. Many of these response curves have a horizontal plateau—the yield stress is nearly a constant for a significantly large range of plastic strain values. If you have data from both uniaxial compression and hydrostatic compression, the plateau values of the two experimental curves can be used to calculate the ratio of k.

| Input File Usage: | *CRUSHABLE FOAM, HARDENING=ISOTROPIC |

| ABAQUS/CAE Usage: | Property module: material editor: Mechanical |

The flow potential for the isotropic hardening model is chosen as

![]()

The plastic flow is associated when the value of ![]() is the same as that of

is the same as that of ![]() . By default, the plastic flow is nonassociated to allow for the independent calibrations of the shape of the yield surface and the plastic Poisson's ratio. If you have information only about the plastic Poisson's ratio and choose to use associated plastic flow, the yield stress ratio k can be calculated from

. By default, the plastic flow is nonassociated to allow for the independent calibrations of the shape of the yield surface and the plastic Poisson's ratio. If you have information only about the plastic Poisson's ratio and choose to use associated plastic flow, the yield stress ratio k can be calculated from

![]()

![]()

| Input File Usage: | *CRUSHABLE FOAM, HARDENING=ISOTROPIC |

| ABAQUS/CAE Usage: | Property module: material editor: Mechanical |

A simple uniaxial compression test is sufficient to define the evolution of the yield surface. The hardening law defines the value of the yield stress in uniaxial compression as a function of the absolute value of the axial plastic strain. The piecewise linear relationship is entered in tabular form. The table must start with a zero plastic strain (corresponding to the virgin state of the materials), and the tabular entries must be given in ascending magnitude of ![]() . For values of plastic strain greater than the last user-specified value, the stress-strain relationship is extrapolated based on the last slope computed from the data. If desired, the yield stress can also be a function of temperature and other predefined field variables.

. For values of plastic strain greater than the last user-specified value, the stress-strain relationship is extrapolated based on the last slope computed from the data. If desired, the yield stress can also be a function of temperature and other predefined field variables.

| Input File Usage: | *CRUSHABLE FOAM HARDENING |

| ABAQUS/CAE Usage: | Property module: material editor: Mechanical |

As strain rates increase, many materials show an increase in the yield stress. For many crushable foam materials this increase in yield stress becomes important when the strain rates are in the range of 0.1–1 per second and can be very important if the strain rates are in the range of 10–100 per second, as commonly occurs in high-energy dynamic events.

Two methods for specifying strain-rate-dependent material behavior are available in ABAQUS as discussed below. Both methods assume that the shapes of the hardening curves at different strain rates are similar, and either can be used in static or dynamic procedures. When rate dependence is included, the static stress-strain hardening behavior must be specified for the crushable foam as described above.

You can specify a Cowper-Symonds overstress power law that defines strain rate dependence. This law has the form

![]()

![]()

The power-law rate dependency can be rewritten in the following form

![]()

| Input File Usage: | Use both of the following options: |

*CRUSHABLE FOAM HARDENING *RATE DEPENDENT, TYPE=POWER LAW |

| ABAQUS/CAE Usage: | Property module: material editor: Mechanical |

Rate-dependent behavior can alternatively be specified by giving a table of the ratio R as a function of the absolute value of the rate of the axial plastic strain and, optionally, temperature and predefined field variables.

| Input File Usage: | Use both of the following options: |

*CRUSHABLE FOAM HARDENING *RATE DEPENDENT, TYPE=YIELD RATIO |

| ABAQUS/CAE Usage: | Property module: material editor: Mechanical |

The crushable foam plasticity model can be used with plane strain, generalized plane strain, axisymmetric, and three-dimensional solid (continuum) elements. This model cannot be used with elements for which the stress state is assumed to be planar (plane stress, shell, and membrane elements) or with beam or truss elements.

In addition to the standard output identifiers available in ABAQUS (“ABAQUS/Standard output variable identifiers,” Section 4.2.1, and “ABAQUS/Explicit output variable identifiers,” Section 4.2.2), the following variable has special meaning for the crushable foam plasticity model:

PEEQ | For the volumetric hardening model, PEEQ is the volumetric compacting plastic strain defined as |

For the volumetric hardening model, the initial values of the volumetric compacting plastic strain can be specified for elements that use the crushable foam material model, as described above. The volumetric compacting plastic strain (output variable PEEQ) provided by ABAQUS then contains the initial value of the volumetric compacting plastic strain plus any additional volumetric compacting plastic strain due to plastic straining during the analysis. However, the plastic strain tensor (output variable PE) contains only the amount of straining due to deformation during the analysis.