Product: ABAQUS/Standard

This example illustrates the use of the frame element FRAME2D. Frame elements (“Frame elements,” Section 23.4.1 of the ABAQUS Analysis User's Manual) can be used to model elastic, elastic-plastic, and buckling strut responses of individual members of frame-like structures. The elastic response is defined by Euler-Bernoulli beam theory. The elastic-plastic response is modeled with nonlinear kinematic hardening plasticity concentrated at the element's ends, simulating the development of plastic hinges. The buckling strut response is a simplified, phenomenological representation of the highly nonlinear cross-section collapse and material yielding that takes place when slender members are loaded in compression .Therefore, frame elements can be elastic, elastic-plastic, behave as struts (with or without buckling), or switch during the analysis to strut behavior followed by postbuckling behavior. Both the elastic-plastic and buckling strut responses are simplifications of highly nonlinear responses. They are designed to approximate these complex responses with a single finite element representing a structural member between connections. For parts of the model where higher solution resolution is required, such as stress prediction, the model should be refined with beam elements.

The geometry in this example is a typical K-frame construction used in applications such as offshore structures (see Figure 1.2.4–1). A push-over analysis is performed to determine the maximum horizontal load that the structure can support before collapse results from the development of plastic hinges or buckling failure. During a push-over test, many structural members are loaded in compression. Slender members loaded in compression often fail due to geometric buckling, cross-section collapse, and/or material yielding. The buckling strut response, which models such compressive behavior, is added in separate simulations to investigate the effect of the compressive failure of critical members in the structure. A dead load is applied to the top of the structure representing the weight supported by the K-frame. Push-over analyses are either load or displacement control tests.

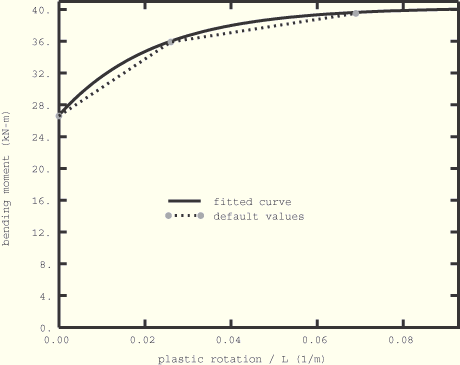

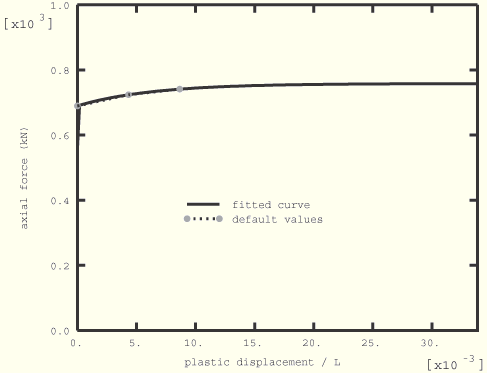

The structure consists of 19 members between structural connections. Each finite element models a member of the frame. Hence, 19 frame elements are used: 17 elements with PIPE cross-sections of varying properties and 2 elements (the top platform) with I cross-sections. The plastic response of the elements is calculated from the yield stress of the material, using the plastic default values provided by ABAQUS. (The default values for the plastic response are based on experiments with slender steel members. For details on the default values, see “Frame section behavior,” Section 23.4.2 of the ABAQUS Analysis User's Manual.) The default plastic response includes mild hardening for axial forces and strong hardening for bending moments. The default hardening responses for a typical element in the model are shown in Figure 1.2.4–2 and Figure 1.2.4–3.

A dead load of 444.8 kN (100,000 lb) is applied to the top of the K-frame, representing the part of the structure above the K-frame. Subsequently, the top platform is loaded or displaced horizontally. The load level or applied displacement is chosen to be large enough so that the entire structure fails by the formation of plastic hinges and, consequently, loses load carrying capacity.

Three different models are investigated. A limit load is expected, since the goal of the analysis is to determine when the structure loses overall stiffness. Large- and small-displacement analyses are performed for all three models for comparison. Large-displacement analyses using frame elements are valid for large overall rotations but small strains, since frame elements assume that the strains are small. In the first model all elements use elastic-plastic material response. In the second model buckling is checked for all elements with PIPE cross-sections. The ISO equation is used as a criteria for buckling, and the default Marshall strut envelope is followed for the postbuckling behavior. The buckling strut envelope is calculated from the yield stress of the material and the default Marshall Strut theory. (For details on the default buckling strut envelope, see “Frame section behavior,” Section 23.4.2 of the ABAQUS Analysis User's Manual.) All frame members that use the BUCKLING parameter on the *FRAME SECTION option check the ISO criteria for the switching-to-strut algorithm. In the third model the member that switches to strut behavior in the second model (element 7) is replaced by a frame element with buckling strut response from the beginning of the analysis. To proceed beyond the unstable phase of the response, the Riks static solution procedure is used in the elastic-plastic problems. To decrease the number of solution iterations, the *CONTROLS option is used in the elastic-plastic problem with large displacement, with the value of the ratio of the largest solution correction to the largest incremental solution set to 1.0, since displacement increments are very small after plasticity occurs.

The structure is loaded or displaced to the point at which all load carrying capacity is lost. In the first model with elastic-plastic frame elements, the results for the linear and nonlinear geometries compare as expected. That is, the limit load for the large-displacement analysis is reached at a load of 1141 kN (256,000 lb) as compared to a higher load of 1290 kN (291,000 lb) in the small-displacement analysis. The plastic hinge pattern is the same in both cases.

The second model uses the switching algorithm. It shows that element 7 first violates the ISO equation (buckles) at a prescribed displacement equal to 1.32 cm (0.52 in), before any elements form plastic hinges. The critical compressive force in this element is –318 kN (–71,400 lb). Next, plasticity develops at several elements, and the structure reaches its limit capacity. The frame elements with the switching algorithm predict the structural behavior in the most accurate way, since the possibility of buckling is checked for all elements in the model, and highly compressed members switch automatically to postbuckling behavior (see the plastic and buckled frame elements in Figure 1.2.4–4). When the structure can no longer support horizontal loading, the patterns of plastic hinges for linear and nonlinear geometry are the same. The results differ more for loads close to the limit load.

To investigate the effect of buckling, the first and the third (element 7 defined with buckling strut response from the beginning) models are compared (kframe_loadcntrl_nlgeom.inp and kframe_dispcntrl_buckle_nlgeom.inp). Load versus horizontal deflection curves for the large-displacement analyses are shown in Figure 1.2.4–5. Similar to the model with switching algorithm, first element 7 buckles. As the other members deform and absorb the load no longer carried by the buckled member, the structure regains stiffness and plasticity develops in other members. When seven members develop plastic hinges, the structure can no longer support additional horizontal loading. The limit load in the third model is only about 28% of the limit load in the model without buckling. The load-displacement curves for the switching algorithm and for the example with element 7 using buckling strut response compare well and are not shown.

Elastic-plastic analysis with load control; large-displacement analysis.

Elastic-plastic analysis with load control; small-displacement analysis.

Elastic-plastic frame element with the switching algorithm and displacement control; large-displacement analysis.

Elastic-plastic frame element with the switching algorithm and displacement control; small-displacement analysis.

Elastic-plastic and buckling strut response with load control; large-displacement analysis.

Elastic-plastic and buckling strut response with displacement control; small-displacement analysis.

Figure 1.2.4–2 Default hardening response for axial force in a typical element with PIPE cross-section (element 7 in the model).

Figure 1.2.4–3 Default hardening response for bending moments in a typical element with PIPE cross-section (element 7 in the model).