Products: ABAQUS/Standard ABAQUS/Explicit ABAQUS/CAE

In ABAQUS the following contact pressure-overclosure relationships can be used to define the contact model:

the “hard” contact relationship minimizes the penetration of slave nodes into the master surface and does not allow the transfer of tensile stress across the interface;

a modified “hard” contact relationship, available only in ABAQUS/Standard, which does allow some limited penetration of the slave nodes into the master surface and some transfer of tensile stress across the interface;

a “softened” contact relationship in which the contact pressure is a linear function of the clearance between the surfaces;

a “softened” contact relationship in which the contact pressure is an exponential function of the clearance between the surfaces (in ABAQUS/Explicit this relationship is available only for the contact pair algorithm);

a “softened” contact relationship in which the contact pressure is a piecewise linear (tabular) function of the clearance between the surfaces; and

a relationship in which there is no separation of the surfaces once they contact (in ABAQUS/Explicit this relationship is available only for the contact pair algorithm).

By default, a “hard” contact pressure-overclosure relationship is used for both surface-based contact and element-based contact. You can include a nondefault contact pressure-overclosure relationship in a specific contact property definition.

| Input File Usage: | Use both of the following options for surface-based contact: |

*SURFACE INTERACTION, NAME=interaction_property_name *SURFACE BEHAVIOR Use both of the following options for element-based contact in ABAQUS/Standard: *INTERFACE or *GAP, ELSET=name *SURFACE BEHAVIOR |

| ABAQUS/CAE Usage: | Interaction module: contact property editor: Mechanical |

| Element-based contact is not supported in ABAQUS/CAE. |

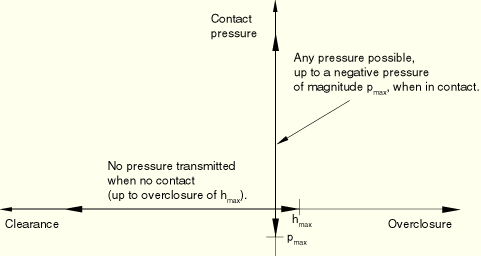

The most common contact pressure-overclosure relationship is shown in Figure 22.1.2–1. When surfaces are in contact, any contact pressure can be transmitted between them. The surfaces separate if the contact pressure reduces to zero. Separated surfaces come into contact when the clearance between them reduces to zero.

Currently two methods of constraint enforcement can be used in ABAQUS/Standard: the classical Lagrange multiplier method or the augmented Lagrangian method. Penalty contact enforcement is used in ABAQUS/Explicit.

The classical Lagrange multiplier method of constraint enforcement, which allows no penetration of the slave nodes into the master surface, is the default “hard” contact relationship.

| Input File Usage: | *SURFACE BEHAVIOR, PRESSURE-OVERCLOSURE=HARD |

| ABAQUS/CAE Usage: | Interaction module: contact property editor: Mechanical |

The augmented Lagrangian method uses the penalty method during each iteration. Iterations continue until convergence in the solution is obtained with the penalty method. If a slave node penetrates the master surface by more than 0.1% of the characteristic interface length, the contact pressure is “augmented” and another series of iterations is executed until convergence is once again achieved. Only when the penetration tolerance requirement is satisfied will the solution be accepted. This method may require additional iterations in some cases; however, this approach is sometimes useful for numerical reasons because it can make the resolution of contact conditions easier.

The augmented Lagrangian method cannot be used in conjunction with debonded surfaces.

| Input File Usage: | *SURFACE BEHAVIOR, AUGMENTED LAGRANGE |

| ABAQUS/CAE Usage: | Interaction module: contact property editor: Mechanical |

You can modify the behavior of the augmented Lagrangian method on a step-by-step basis by specifying a scale factor for the penalty stiffness. In addition, you can change the default penetration tolerance of 0.1% of the characteristic interface length. Choosing a small penetration tolerance or a high penalty stiffness may result in an excessive number of iterations or convergence difficulties.

| Input File Usage: | *CONTACT CONTROLS, STIFFNESS SCALE FACTOR=factor, ABSOLUTE PENETRATION TOLERANCE=tolerance, RELATIVE PENETRATION TOLERANCE=tolerance |

| ABAQUS/CAE Usage: | Interaction module: ABAQUS/Standard contact controls editor: Stiffness scale factor: factor, Penetration tolerance: Absolute: tolerance or Relative: tolerance |

With the default penalty contact enforcement in ABAQUS/Explicit, the “hard” contact relationship is approximated by stiff linear behavior (the stiffness is adjusted automatically to minimize penetrations without adversely affecting the time increment; see “Contact formulation for ABAQUS/Explicit contact pairs,” Section 21.4.4).

| Input File Usage: | *SURFACE BEHAVIOR, PRESSURE-OVERCLOSURE=HARD |

| ABAQUS/CAE Usage: | Interaction module: contact property editor: Mechanical |

In ABAQUS/Standard you can define a modified “hard” contact pressure-overclosure relationship on a step-by-step basis. You can modify the default “hard” contact relationship to allow up to ![]() points on a surface to “overclose” by a certain distance,

points on a surface to “overclose” by a certain distance, ![]() , before contact pressure is transmitted. If the overclosure exceeds

, before contact pressure is transmitted. If the overclosure exceeds ![]() , the contact state is changed from open to closed, the slave node is moved back to the master surface, and “hard” contact is enforced. You can also modify the default relationship to allow the surfaces to transmit “tensile” contact pressures up to a particular value,

, the contact state is changed from open to closed, the slave node is moved back to the master surface, and “hard” contact is enforced. You can also modify the default relationship to allow the surfaces to transmit “tensile” contact pressures up to a particular value, ![]() , before they separate, as shown in Figure 22.1.2–2. If either

, before they separate, as shown in Figure 22.1.2–2. If either ![]() or

or ![]() is exceeded at a node, ABAQUS will change the contact status.

is exceeded at a node, ABAQUS will change the contact status.

Figure 22.1.2–2 Pressure-overclosure relationship with possible negative pressure transmission (cohesion) and/or overclosure.

During an increment in which the contact status has changed, ABAQUS/Standard will use the default “hard” contact criterion to determine whether the change should be reversed. In other words, if the contact status changes from “open” to “closed” during an increment, the contact pressure must remain positive for the changed status to persist. In subsequent increments the contact point can again sustain tensile pressures up to a value of ![]() before the surfaces separate.

before the surfaces separate.

This contact pressure-overclosure relationship is useful for cases where negative pressure values (surface cohesion) may be allowed physically; for example, in the case of sticky surfaces. It can also be useful in overcoming numerical problems in difficult contact simulations and in obtaining solutions without excessive iteration (see “Common difficulties associated with contact modeling in ABAQUS/Standard,” Section 21.2.9).

| Input File Usage: | *CONTACT CONTROLS, UERRMX= |

| ABAQUS/CAE Usage: | Interaction module: ABAQUS/Standard contact controls editor: Max number of points that can violate contact: |

Three types of “softened” contact relationships are available in ABAQUS. The pressure-overclosure relationship can be prescribed by using a linear law, a tabular piecewise-linear law, or an exponential law (in ABAQUS/Explicit available only with the contact pair algorithm).

For contact involving element-based surfaces and for element-based contact (available only in ABAQUS/Standard), the “softened” contact relationships are specified in terms of overclosure (or clearance) versus contact pressure. For contact involving a node-based surface or nodal contact elements (such as GAP and ITT elements) for which an area or length dimension is not defined, softened contact is specified in terms of overclosure (or clearance) versus contact force. For slave surfaces on beam-type elements, specify pressure as force per unit length.

When using softened contact relationships that have nonzero pressure at zero overclosure (not allowed with the general contact algorithm) in ABAQUS/Explicit, you should be aware that initial, nonequilibrated contact pressures may be present in the analysis (see “Adjusting initial surface positions and specifying initial clearances in ABAQUS/Explicit contact pairs,” Section 21.4.5).

The “softened” contact pressure-overclosure relationships might be used to model a soft, thin layer on one or both surfaces. In ABAQUS/Standard they are also sometimes useful for numerical reasons because they can make it easier to resolve the contact condition.

Use the softened contact relationship with caution in implicit dynamic impact simulations. If this relationship is used in such a simulation, ABAQUS/Standard will not use the impact algorithm, which destroys kinetic energy of the nodes on the surface when impact occurs, but will instead assume a perfectly elastic collision. The consequence of this change is that the slave nodes bounce back immediately after impact with the master surface; hence, extensive “chattering” may result, leading to convergence problems and small time increments.

However, softened contact may work well in implicit dynamic calculations where impact effects are not important; for example, if contact changes are primarily due to sliding motion along a curved surface, such as may occur in low-speed metal forming applications.

In ABAQUS/Explicit softened contact can be enforced with either the kinematic or the penalty constraint enforcement method (see “Contact formulation for general contact,” Section 21.3.4, and “Contact formulation for ABAQUS/Explicit contact pairs,” Section 21.4.4, for details). With penalty enforcement the contact collisions are elastic except for the influence of contact damping, whereas with softened kinematic contact some energy will be absorbed by the impact because of algorithmic characteristics: the energy absorbed tends to increase as the contact stiffness increases. Another consideration is the effect on the time increment: with kinematic enforcement the stable time increment is independent of the contact stiffness, but with penalty contact the time increment decreases as the contact stiffness increases.

In a linear pressure-overclosure relationship the surfaces transmit contact pressure when the overclosure between them, measured in the contact (normal) direction, is greater than zero. The linear pressure-overclosure relationship is identical to a tabular relationship with two data points, where the first point is located at the origin.

You specify the slope of the pressure-overclosure relationship, ![]() .

.

| Input File Usage: | *SURFACE BEHAVIOR, PRESSURE-OVERCLOSURE=LINEAR |

| ABAQUS/CAE Usage: | Interaction module: contact property editor: Mechanical |

To define a piecewise-linear pressure-overclosure relationship in tabular form, as shown in Figure 22.1.2–3, you specify data pairs (![]() ,

, ![]() ) of pressure versus overclosure (where overclosure corresponds to negative clearance). You must specify the data as an increasing function of pressure and overclosure. In this relationship the surfaces transmit contact pressure when the overclosure between them, measured in the contact (normal) direction, is greater than

) of pressure versus overclosure (where overclosure corresponds to negative clearance). You must specify the data as an increasing function of pressure and overclosure. In this relationship the surfaces transmit contact pressure when the overclosure between them, measured in the contact (normal) direction, is greater than ![]() , where

, where ![]() is the overclosure at zero pressure. For the general contact algorithm in ABAQUS/Explicit

is the overclosure at zero pressure. For the general contact algorithm in ABAQUS/Explicit ![]() must be zero. For overclosures greater than

must be zero. For overclosures greater than ![]() the pressure-overclosure relationship is extrapolated based on the last slope computed from the user-specified data (see Figure 22.1.2–3).

the pressure-overclosure relationship is extrapolated based on the last slope computed from the user-specified data (see Figure 22.1.2–3).

| Input File Usage: | *SURFACE BEHAVIOR, PRESSURE-OVERCLOSURE=TABULAR |

| ABAQUS/CAE Usage: | Interaction module: contact property editor: Mechanical |

In an exponential (soft) contact pressure-overclosure relationship the surfaces begin to transmit contact pressure once the clearance between them, measured in the contact (normal) direction, reduces to ![]() . The contact pressure transmitted between the surfaces then increases exponentially as the clearance continues to diminish. Figure 22.1.2–4 illustrates this behavior in ABAQUS/Standard. In ABAQUS/Explicit this behavior is available only for the contact pair algorithm.

. The contact pressure transmitted between the surfaces then increases exponentially as the clearance continues to diminish. Figure 22.1.2–4 illustrates this behavior in ABAQUS/Standard. In ABAQUS/Explicit this behavior is available only for the contact pair algorithm.

You specify ![]() ; the contact pressure at zero clearance,

; the contact pressure at zero clearance, ![]() ; and, optionally in ABAQUS/Explicit,

; and, optionally in ABAQUS/Explicit, ![]() .

.

| Input File Usage: | *SURFACE BEHAVIOR, PRESSURE-OVERCLOSURE=EXPONENTIAL |

| ABAQUS/CAE Usage: | Interaction module: contact property editor: Mechanical |

You can indicate that ABAQUS should use the contact pressure-overclosure relationship that prevents surfaces from separating once they have come into contact. In ABAQUS/Explicit this relationship can be specified only for pure master-slave contact pairs and cannot be used with adaptive meshing or with the general contact algorithm.

The no separation relationship is often used with the rough friction model (see “Frictional behavior,” Section 22.1.4) to model nonintermittent, rough frictional contact. Using this combination of surface interaction models causes surfaces to remain fully bonded together (no separation and no tangential sliding) once they contact, even if the contact pressure between them is tensile.

| Input File Usage: | *SURFACE BEHAVIOR, NO SEPARATION |

| ABAQUS/CAE Usage: | Interaction module: contact property editor: Mechanical |

In ABAQUS/Explicit if a softened contact relationship is specified with the no separation relationship, the pressure-overclosure relationship will include tensile behavior. The exponential relationship cannot be used with no separation behavior. For the tabular relationship, a point must be specified on the zero pressure axis, and the slope will continue into the tensile regime following the same slope as the first two data points (see Figure 22.1.2–6). The linear relationship will have a linear tensile pressure-overclosure relationship with the same slope that is used for the compressive behavior.

ABAQUS/Standard provides both the clearance, COPEN, and the contact pressure, CPRESS, as output to the data, results, and output database files. Output to these files is requested as described in “Output to the data and results files,” Section 4.1.2, and “Output to the output database,” Section 4.1.3.

ABAQUS/Explicit provides the contact pressure, CPRESS, as output to the output database file (see “Output to the output database,” Section 4.1.3, for details).

In data or results file output the CPRESS output variable gives viscous damping pressures for an open slave node. This variable also gives the contact pressure for a closed slave node. In printed output a “VD” status indicates that the forces are for viscous damping.

Contours of the contact pressure on the slave surface can be plotted in ABAQUS/CAE.