GraviCase Log

Contents

- 1 Weekly Log for GraviCase Project

- 2 Week 1 (September 1 - September 5):

- 3 Week 2 (September 5 - September 12):

- 4 Week 3 (September 12 - September 19):

- 5 Week 4 (September 19 - September 26):

- 6 Week 5 (September 26 - October 3):

- 7 Week 6 (October 3 - October 10):

- 8 Week 7 (October 10 - October 20):

- 9 Week 8 (October 20 - October 23):

- 10 Week 9 (October 23 - October 31):

- 11 Week 10 (October 31 - November 7):

- 12 Week 11 (November 7 - November 14):

- 13 Week 12-13 (November 14 - November 26 (Thanksgiving Break Included)):

- 14 Week 13-14 (November 27 - December 1 (Demo Day)):

- 15 Week 15-16 (December 1 - December 11):

Weekly Log for GraviCase Project

- PUT IN TIME AMOUNTS

By Matt Rocco and Michael Morgan

Link to the GraviCase wiki Page: here.

Week 1 (September 1 - September 5):

"Decided" on project, started to gameplan objectives and obstacles of project, began to think of how to accomplish goals and design / build our project. Ironing out details on what skillsets we will have to pick up / refresh to accomplish our design. Created wiki and weekly log.

Week 2 (September 5 - September 12):

Due to concerns about both the feasibility and safety of our project, we have begun researching into some of the individual parts of our project.

- We want a cheap effective way to make and test our project.

- Airbag portion of our idea as the elephant in the room as far as cost is concerned.

We have begun research into a way to inflate our airbag safely and quickly enough to meet the safety and usefulness goals we have set for our project.

- Originally we leaned towards a chemically inflated airbag

- Our TA has suggested we use compressed air which will be :

- Safer

- Cheaper

- Most realistic.

Researching into personal airbags, especially ones powered with compressed air. Started design on our product with a focus and concern on the following:

- Powering mechanism

- Airbag shape

- Airbag inflating mechanism

- Preventing premature / unnecessary airbag inflation

- I have an idea related to a CSE132 lab I did involving peak detection to count "steps" on the arduino platform, and we believe that this may be the most effective way for us to ensure it doesn't inflate prematurely.

- Filling the airbag in time (needs to be able to inflate in the time it takes to hit the ground

- Preventing premature / unnecessary airbag inflation

We have a few ideas related to this: we have a rudimentary idea of how we want the airbag shaped. However, more research and discussion is necessary for the powering and inflating parts of our project.

Week 3 (September 12 - September 19):

We met with our TA, Andrew, on Tuesday and Professor Feher on Friday to discuss our project and we have moved towards the idea of our project being more of a prototype then a finished project. We also opened ourselves up to the idea of it being a case for any electronics which would help with our size constraints.

- One issue we still have is with safety

- Through our meetings we have discussed our accelerometer peak detection idea which we see as viable and if we transition to a non phone case this will allow us to not worry so much about everyday movement.

- Additionally we have decided on compressed air as our main method of airbag filling, and while we were worried about our method of puncturing it, Andrew told us he believes there is a valve attachment for Arduino which we could use. We have begun researching this and currently it is our primary way of filling our airbag.

- We believe compressed air will be much safer than the chemical explosion used to fill a car airbag, it also makes it easy to replace and test the airbag with refillable CO2 cartridges.

- Our other main obstacle is cost which is primarily due to the airbag:

- Andrew recommended trying to make our own, or at least experiment with makeshift materials so we could get an idea as to the shape and size of the airbag.

- We were unable to get out this weekend to get testing materials, but we plan on doing so later this week. However, the main focus of our past week has been on improving the website and also working out the cost related issues of our project.

- Professor Feher recommended finding someone with origami skills so that we could work on an efficiently folded and easily deployable airbag. He also agreeded with Andrews suggestion above and suggested that once we got the shape and size of our airbag down that we try to find people with structural engineering / material science backgrounds to help us find a workable and durable material.

- Andrew recommended trying to make our own, or at least experiment with makeshift materials so we could get an idea as to the shape and size of the airbag.

Week 4 (September 19 - September 26):

We purchased some materials to test airbags (glue gun and trash bags) and intend to do some minor designing and testing work on the shape and packaging of our airbag with trash bags before working on finding a more suitable / long term material.

- Michael Morgan has begun work on airbag design.

I (Matt Rocco) refreshed myself on Arduino today, discovering some Mac compatibility issues with the program. However, after taking an hour to resolve those issues, I wrote a rudimentary blink program just to confirm my understanding of the code. I have begun working on a program for our accelerometer which would send voltage to a port after sensing that it was being dropped (3 hours). Recap:

- Wrote basic blink program

- Began work on an accelerometer triggered.

- We believe that we can power our valve by sending voltage (which we may have to step up / transform) through one of our ports so this is out intent with the accelerometer program.

MorganRocco4EVA (talk) 19:08, 24 September 2017 (CDT)

Week 5 (September 26 - October 3):

We started experimenting more quantitatively with our airbag design with a large focus on volume.

- We have determined that an 8 oz. cartridge of CO2 is the most cost effective and also the best size.

- We found that 1 gallon of air amounts to 7 grams of compressed CO2, so generally we know that 8 oz. of CO2 will give us a little more than a gallon of volume in our airbag.

- In order to discover the approximate volume of our airbag, Michael Morgan filled it with water and then measured the amount of water we needed to fill it. We found this amount to be about 12 cups of water (3/4 of a gallon), however, in our final design we would like to have a larger airbag so we believe that the gallon of air that we will get from the 8g CO2 cartridge that we get will be perfect.

- We found that 1 gallon of air amounts to 7 grams of compressed CO2, so generally we know that 8 oz. of CO2 will give us a little more than a gallon of volume in our airbag.

Matthew also continued work on the Arduino code: hooking up the accelerometer to the Arduino and beginning to figure out a method to make our case feel that it is dropping. Additionally, thanks to a suggestion from a fellow ESE 205 student during our presentation, we plan on incorporating "tumbling" into sensing if our device is dropping.

- A falling phone is likely to "tumble" / flip around as it falls, we can sense this with a gyroscope (which we have on our accelerometer model: GY-521). If we incorporate this into our formula for falling, we believe it will lead to an overall safer and less likely to inflate at the wrong time airbag design.

MorganRocco4EVA (talk) 20:53, 1 October 2017 (CDT)

Week 6 (October 3 - October 10):

We ordered our parts for the mechanical side of the project:

- A 12V DC solenoid valve

- It is larger than we expected (no description of its size online) so it is a new found challenge, however, now we have some physical objects which we can start positioning to get an idea for the layout of our project's shape and design.

- Pneumatic tubing

- 16 oz. CO2 cartridges (8oz. are more expensive relatively so we intend to get 2 airbag "fills" per cartridge

- We have ran into a cost related problem with CO2 cartridges as they are not as cheap as we recall seeing when we looked earlier.

- Hose clamps and some valve attachments in order to connect the various parts

We have begun laying out the components, but we have also started designing the systems connection to the airbag. Due to getting the wrong sized valve attachment on the CO2 to solenoid valve end, we are currently only working on the valve through to the airbag side of the system so far. Later this week I intend on writing some quick code to ensure my understanding of the valve is correct and to see that it opens quickly enough. After that is successful, we will integrate that with our existing code and then begin integrating that into the system as a whole. Additionally, Michael has been focusing on refreshing himself with CAD and 3-D printing as we see ourselves transitioning towards that when we begin to tackle mounting the components of our system onto a case or other kind of harness. Continued work on Arduino code:

- Needs to sense that it is dropping (z input from Accelerometer)

- Setting a threshold amount for it falling so that it does not go off when unnecessary

- Needs to be able to sense it is tumbling (gyroscope)

- Setting a tumbling threshold for both values so that it does not blow up unnecessarily

Creating a rolling average of accelerometer and tumbling data so that the Arduino can decide if it being dropped

- Deciding on size of buffer

MorganRocco4EVA (talk) 12:59, 9 October 2017 (CDT)

Week 7 (October 10 - October 20):

We have all of our parts, and have drawn up some preliminary designs for the layout of the case.

- We have some minor size issues related to our valves, but we plan to go and get adapters or print them ourselves.

- At the suggestion of our TA, Andrew, we are looking into getting sealant to apply to our various connectors so that they will remain airtight

- Depending on how permanent the sealing material is, we may only apply it to the static parts of our system (i.e. avoiding it on the CO2 screw in location because it needs to be swapped in and out as it runs out).

Michael is designing a 3D printed part which will screw into the CO2 side of our valve.

- This component will have a sharp point facing the side where the CO2 cartridge is inserted.

- The purpose of this piece is to puncture the CO2 cartridge so that it is ready to go once the solenoid valve switches open.

I am continuing work on the accelerometer code (5 hours)

- I have been working on how to compactly wire the accelerometer to the Arduino so that the system is robust (as it is being dropped as well as attached to an exploding airbag) and also space efficient.

We have fallen behind a little on the airbag design, currently we need to focus on how to shape it so that it can protect the sides and front of the device.

- The working idea we have right now is a sort of trough like design. However, we do not know how to build a deflated airbag which fills to this parameter.

Week 8 (October 20 - October 23):

Thanks to a suggestion from Andrew, in addition to creating our original idea on how to puncture the CO2 cartridge, we are also looking into hollowing out (drilling a hole through the middle of) a bolt which we would screw into the CO2 side of our valve that will function as an adapter between our valve and the CO2 cartridge. We are still working on ways to attach some kind of spike to this adapter so that the CO2 cartridge punctures when it is screwed into place.

- At Andrew's suggestion we popped a CO2 cartridge into our airbag system so get an idea of if our earlier approximations were accurate.

- We ran into a new obstacle, which is the CO2 cartridge getting fairly cold (frost build up on the cartridge) as it is dispensing air. However, we do not think that this will effect performance of our device, it will only make it a little cold to replace.

- We also did a quick test of our DC solenoid valve, we ran DC current from a wall outlet into it to make sure that it opens and closes.

- While you cannot really see it opening, the valve makes a distinct click when you plug run voltage across it

- I did a quick test with water (as we do not yet have our CO2 linked up with our valve) and the water does not flow through the valve until voltage is run across it, as expected.

I am continuing work on our code (2 hours)

- Currently we have our raw values from the accelerometer and gyroscope (we found code for this online, and I spent time making sure that I understand it)

- My goal for the middle of the week is to process these raw values into ones that we can actually understand, and then use these to calculate whether or not our device is falling;

- This was completed Monday night, we now can convert our raw values into more quantifiable numbers.

- Once this is done, we will draft up a circuit so that we can run the correct amount of voltage through in order to power the valve (which will likely need an external 12V power supply, as the Arduino can only output 5V)

- My goal for the middle of the week is to process these raw values into ones that we can actually understand, and then use these to calculate whether or not our device is falling;

Week 9 (October 23 - October 31):

Michael Morgan designed a part which will serve as an adapter to our CO2 to valve side, as well as hold in place a thin metal tube (which we purchased).

- Andrew said he will print this part for us once we have accurate dimensions of our pieces.

- The tube is hollow which will allow air to flow through it. We also picked its dimensions so that it will be able to maximize the puncture on our CO2 canister when it is screwed in, leading to an air tight fit with the highest possible air flow.

- Additionally we have been working on the airbag design still. Professor Feher, suggested we use the strong, yet breathable material Tyvek. This material will allow us to easily shape and influence our airbag design, while also serving as a tough, mostly air tight material to contain the CO2.

- It may seem that having a not entirely airtight airbag material is a bad idea for our project, however, we believe that as long as the airflow out is limited (i.e. it wont all go out upon impact) then it solves the problem of both protecting and cushioning our device from a drop as well being able to deflate easily and be reused.

- We currently have an order of Tyvek in the mail, and it should arrive Monday 10/30 or Tuesday 10/31.

- It may seem that having a not entirely airtight airbag material is a bad idea for our project, however, we believe that as long as the airflow out is limited (i.e. it wont all go out upon impact) then it solves the problem of both protecting and cushioning our device from a drop as well being able to deflate easily and be reused.

I have continued work upon the code, as well as ventured slightly into soldering a board for us to work with.

- We found that the test system we had put together was not durable enough for us to test with, as the wires frequently would come out leading the system to not respond as we needed.

- Without a robust system we have not been able to gather data to put together accurate threshold values, so we see this next step as helping us to solve our bigger data related problem.

- Professor Feher has told me to graph the acceleration values to see if there is a trend with our triggering value, this will be the method I will strive to use for determining threshold values of our system

- We also have a few suggested tests related to safety from Professor Feher and Andrew. They advised to go up and down the stairs to see if our code triggers, this will allow us to work out some of the safety related (pre-mature detonation) issues with our system.

- Without a robust system we have not been able to gather data to put together accurate threshold values, so we see this next step as helping us to solve our bigger data related problem.

I am still working on this code, and expect to do some more code and soldering tonight and tomorrow (total so far 4 hours). Additionally, I still have to figure out the gyroscope, which I have no experience with and is taking some time. Update: We have used Tyvek to make a prototype airbag that can hold air and is approximately the right size for testing. We used one of our CO2 canisters to fill the bag and it filled relatively quickly. We should be able to proceed with more testing very soon. Also, we have ordered a small metal tube from McMaster Carr that we plan on attaching to our valve so that the CO2 canister can be easily popped.

Week 10 (October 31 - November 7):

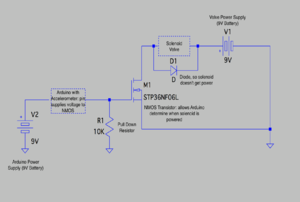

I have been working on figuring out how to incorporate the transistor for our valve system as well as working through some coding related bugs (3 hours). Doing so will allow us to have the necessary voltage to power our DC solenoid valve with an external power supply (i.e. the voltage is not from the Arduino). In theory, the transistor should work as so:

- The DC power supply will be hooked up to the Drain

- This provides the voltage to the system, when the Arduino is not outputting voltage, the MOSFET will be closed; preventing the DC voltage from being supplied to the valve.

- The Arduino output will be hooked up to the Gate

- When the Arduino senses that it is falling, it will provide voltage to the output port, allowing the DC voltage to power our valve

- The Valve will be hooked up to the Source

- The valve will open if the MOSFET is opened, allowing the power source voltage to come through.

Currently, I have been having issues with the transistor working. It is not allowing the drain voltage through, even when supplied with a constant voltage in the ground (hooked up to 5V port on Arduino) so I know that it is not a code related issue. I still have not been able to get to work, but I hope that tonight (November 6th) I can get it working so we can show Andrew in our meeting. One issues (brought to my attention by Andrew) that I need to test is if it is a lack of a universal ground, I was not grounding my circuit to the same ground.

Week 11 (November 7 - November 14):

I have gotten the transistor to work, however, it has opened my eyes to a new problem. When testing our transistor with an LED it works fine, however, due to the 12 voltage requirement of our solenoid valve, there is not enough voltage to open the valve. I believe this will be able to be quickly resolved with a 12V battery but this adds another per unit cost to our device.

- After some mental thought experiments and considering previous experience, I realized that the outlet plug we have been using to simulate our power supply works on the valve (when plugged in directly), therefore the voltage it is providing is not the reason that the valve is not opening. Instead I have rationalized it to being that the code currently does not last long enough for the valve to open itself (i.e. the voltage is going through the valve but we do not notice as we do not hear the distinct click it makes when it opens unlike with the bright LED).

- I am going to test this and incorporate delta timing into the code so that it still runs while also delaying.

Michael has been working on airbag design, currently we are using tape to simulate where we would internally sew our airbag. He is experimenting with a couple of different airbag shapes and designs as well as folding and reusing these airbags. Once we have a design we like, we intend to create multiple copies for our demo in case of breakage (but we hope that this won't be necessary).

Week 12-13 (November 14 - November 26 (Thanksgiving Break Included)):

We have achieved a finalized design for our airbag, and made some progress related to the transistor.

- I have restructured the transistor circuit so that it will should be working and I have switched the digital output pin on the Arduino as it was behaving weirdly (initializing at a non-zero value)

- The current transistor circuit is shown to the right:

I do not understand why the circuit is not working, from measurements with my multimeter as well as looking on line, I see no reason that my circuit should not work.

- I now understand why the valve would open regardless of the MOSFET being opened or closed. Because of a lack of a diode in parallel with the valve, the voltage of the battery was able to work through / around the FET and open the valve. In order to combat this, I have put a diode in parallel with the valve.

Andrew originally finished the custom made part we designed for popping our CO2 canisters, however, the canisters themselves do not fit! We believe we may have made an error while measuring even though the three of us (Myself, Michael, and Andrew) all measured the part together. Andrew is working on quickly making a correctly sized part before we leave for Thanksgiving.

- Thanks to Andrew's quick turn around, he was able to get us the custom made part on our way out the door for break. Before we left we tested it on the some canisters, and it works perfectly! The only issue was that I had the empty (emphasis on empty) CO2 canisters I tried to bring back with me confiscated by TSA on my journey through security. This prevented me from being able to work on sizing related stuff regarding the spacing of our project.

Over break, we continued to work out some of the remaining kinks. I have a circuit that I am confident in, yet it still fails to work. My mother sewed our airbag design and we were able to test it by blowing into it.

- Once we get back our plan is to test the system as a whole and work out the remaining kinks before the demo.

- The airbag serves the purposes we want so far (tested by blowing into it by mouth):

- It is resistant to being dropped (stays inflated, high tension)

- It is easy to deflate by hand due to the porous nature of the Tyvek

- it easily folds onto the back of our device

Towards the end of break we began work on our poster, and Michael has sent over the first draft to Andrew for review.

Week 13-14 (November 27 - December 1 (Demo Day)):

There is good news and bad news:

Good News:

- The part works great, it perfectly allows the air to go from the CO2 canister to the airbag.

- A small issue with this is related to air-tightness. At most of the threaded sections, we are getting air leakage, Professor Feher suggested using Teflon tape before break in order to air-tight these joints.

- The Teflon tape works perfectly and it does a great job of air-tighting all of the places where we previously had leaks. Currently, our system is completely airtight.

- A small issue with this is related to air-tightness. At most of the threaded sections, we are getting air leakage, Professor Feher suggested using Teflon tape before break in order to air-tight these joints.

- After switching MOSFETs to a new one, we found out that we burned out the old one at some point in our testing. This is likely the root cause of our problems as the circuit now works with the fresh MOSFET.

- Small issue is that the code is still a little buggy, however, I believe it will be a quick fix now that the circuit is working.

Bad News:

- The CO2 canister totally "busts" through our solenoid valve. We quickly discovered that regardless of whether or not the valve is opened or closed, the air from the CO2 canister will get through the valve.

- This is due to the fact that the pressure coming out of a CO2 canister is 800-900 PSI and our valve is only pressure rated for up to 150 PSI. We did not consider pressure ratings when we purchased our valve and now need to come up with a quick solution to this issue.

- We have purchased an air pressure regulator to step down the 800-900 PSI coming out of the CO2 to a more manageable 150 PSI for our valve. This allows our valve system to work, however, the regulator is a huge component that significantly redefines the size and weight of our device. Unfortunately, it is a necessity as it is too late to buy a higher rated pressure valve which we would have done had we caught out valve issue earlier on.

- This is due to the fact that the pressure coming out of a CO2 canister is 800-900 PSI and our valve is only pressure rated for up to 150 PSI. We did not consider pressure ratings when we purchased our valve and now need to come up with a quick solution to this issue.

- Big issue on the night before the demo, while fine tuning the regulator so that we could maximize air flow without breaking through our valve, our project "exploded." Due to our airtight system, the pressure built up to a point that the CO2 canister exploded out of the custom made part (stripping it in the process so that it is now unusable) even though we let the pressure die down (or so we thought) before slowly unscrewing it, stopping when we got leakage until it stopped.

- This renders our project now unusable. Because the custom part is broken, we are unable to screw in, secure, and pop CO2 canisters and thus are no longer able to demo our project. We sill still be able to demo the strength of our Tyvek airbag by inflating it by hand, as well as demonstrating how easy it is to deflate. We can also showcase the valve opening in response to being dropped, as the valve makes a distinct click when it opens. This will allow us to showcase that the valve opens when dropped, but we no longer have CO2 waiting to rush into the airbag when this happens.

Week 15-16 (December 1 - December 11):

We are working on our final proposal and the tutorials that we chose. Michael and I are working on Airflow Control and Quick Guide to the Wiki respectively.

- We are writing them separately and then editing each others.

- We are cleaning up some parts of our wiki and adding the finishing touches (lots of pictures) to the various sections.

We have decided to standardize the log so that it looks consistent and professional, so I converted the first log entry into a more digestable, bullet point form. This is the last log entry for Gravicase, we are proud of the product that we produced. While it may have exploded on us in the end, we learned a valuable lessons that will help us in future projects as engineers.