Products: ABAQUS/Standard ABAQUS/Explicit

Hydrostatic fluid elements:

are provided to model fluid-filled cavities;

are applicable only for situations where the pressure and temperature of the fluid in a particular cavity are uniform at any point in time;

associated with a given cavity share a common node known as the cavity reference node; and

cannot be used with pore fluid elements or acoustic elements.

First-order axisymmetric, two-dimensional, and three-dimensional hydrostatic fluid elements are provided so that displacement compatibility can be maintained. There are no second-order hydrostatic fluid elements in this release of ABAQUS.

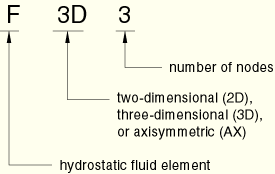

Hydrostatic fluid elements in ABAQUS are named as follows:

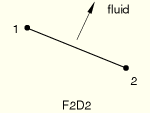

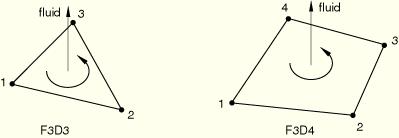

For hydrostatic fluid elements the positive normal direction is given by the right-hand rule going around the nodes of the element in the order that they are given in the element definition. See Figure 26.8.1–1.

The positive direction along the normal must point into the fluid.

All hydrostatic fluid elements associated with a given cavity share a common node known as the cavity reference node. This cavity reference node has a single degree of freedom (degree of freedom 8) representing the pressure inside the fluid cavity.

A fluid cavity reference node should not be used to define the nodes of other element types except for fluid link elements. The location of the cavity reference node depends on the model geometry (see “Modeling fluid-filled cavities,” Section 11.5.1, for details).

| Input File Usage: | *FLUID PROPERTY, REF NODE=cavity_reference_node_number |

The elements are intended for applications where the fluid pressure and temperature in the cavity may vary during the analysis, but pressure and temperature gradients in any cavity are assumed to be negligible. Because the pressure gradient vanishes, inertia effects are ignored if these elements are used in a dynamic procedure (see “Modeling fluid-filled cavities,” Section 11.5.1).