Products: ABAQUS/Standard ABAQUS/Explicit

This example problem demonstrates the following ABAQUS features and techniques:

transferring results from ABAQUS/Explicit to ABAQUS/Standard using the import analysis technique;

comparing results from an analysis sequence that uses ABAQUS/Explicit for a forming step and ABAQUS/Standard for a springback analysis with results obtained using ABAQUS/Standard for both the forming and springback steps; and

comparing characteristics of different contact formulations with finite sliding, especially with regard to the treatment of surface thickness.

This example illustrates the forming of a three-dimensional shape by a deep drawing process. In general, the forming procedure involves a forming step followed by a springback that occurs after the blank is removed from the tool. The goal of analyzing the forming procedure is to determine the final deformed shape after springback.

The blank is initially square, 200 mm by 200 mm, and is 0.82 mm thick. The rigid die is a flat surface with a square hole 102.5 mm by 102.5 mm, rounded at the edges with a radius of 10 mm. The rigid square punch measures 100 mm by 100 mm and is rounded at the edges with the same 10 mm radius. The rigid blank holder can be considered a flat plate, since the blank never comes close to its edges. The geometry of these rigid parts is illustrated in Figure 1.5.2–1.

The blank is made of aluminum-killed steel, which is assumed to satisfy the Ramberg-Osgood relation between true stress and logarithmic strain,

![]()

Given the symmetry of the problem, it is sufficient to model only a one-eighth sector of the box. However, for easier visualization we have employed a one-quarter model. Symmetry boundary conditions are applied at the quarter edges of the blank. The punch and the blank holders are allowed to move only in the vertical direction. Allowing vertical motion of the blank holders accommodates changes in the blank thickness during forming.

The most efficient way to analyze this type of problem is to analyze the forming step using ABAQUS/Explicit and to import the results in ABAQUS/Standard to analyze the springback. For verification purposes the complete analysis is also carried out with ABAQUS/Standard. However, this is computationally more expensive and will be prohibitively more expensive for simulation of the forming of realistic, complex components.

This problem is used in Nagtegaal and Taylor (1991) where implicit and explicit finite element techniques for forming problems are compared. The computer time involved in running the simulation using explicit time integration with a given mesh is directly proportional to the time period of the event, since the stable time increment size is a function of the mesh size (length) and the material stiffness. Thus, it is usually desirable to run the simulation at an artificially high speed compared to the physical process. If the speed in the simulation is increased too much, the solution does not correspond to the low-speed physical problem; i.e., inertial effects begin to dominate. In a typical forming process the punch may move at speeds on the order of 1 m/sec, which is extremely slow compared to typical wave speeds in the materials to be formed (the wave speed in steel is approximately 5000 m/sec). In general, inertia forces will not play a dominant role for forming rates that are considerably higher than the nominal 1 m/sec rates found in the physical problem. Therefore, explicit solutions are obtained with punch speeds of 10, 30, and 100 m/sec for comparison with the static solution obtained with ABAQUS/Standard. In the results presented here, the drawing process is simulated by moving the reference node for the punch downward through a total distance of 36 mm in 0.0036 seconds. A detailed comparison of analyses of various metal forming problems using explicit dynamic and static procedures is discussed in the paper by Nagtegaal and Taylor (1991).

Although this example does not contain rate-dependent material properties, it is common in sheet metal forming applications for this to be a consideration. If the material is rate-dependent, the velocities cannot be artificially increased without affecting the material response. Instead, the analyst can use the technique of mass scaling to adjust the effective punch velocity without altering the material properties. “Rolling of thick plates,” Section 1.3.6, contains an explanation and an example of the mass scaling technique.

| Forming analysis with ABAQUS/Explicit. | Case 1a | Using the general contact capability. |

| Case 1b | Using the kinematic contact pairs. | |

| Case 1c | Using penalty contact pairs. | |

| Case 1d | Forming analysis of a fine mesh case using the general contact capability (included for the sole purpose of testing the performance of the ABAQUS/Explicit code). | |

| Case 1e | Forming analysis of a fine mesh case using kinematic contact pairs (included for the sole purpose of testing the performance of the ABAQUS/Explicit code). | |

| Springback analysis with ABAQUS/Standard. | Case 2a | ABAQUS/Standard springback analysis using the *IMPORT, UPDATE=NO option. |

| Case 2b | ABAQUS/Standard springback analysis using the *IMPORT, UPDATE=YES option. | |

| Case 2c | Springback analysis of a fine mesh case (included for the sole purpose of testing the performance of the ABAQUS/Standard code) using the *IMPORT, UPDATE=YES option. | |

| Forming and springback analysis with ABAQUS/Standard. | Case 3a | Using the surface-to-surface contact formulation. |

| Case 3b | Using the node-to-surface contact formulation. |

As described earlier, the import capability in ABAQUS is utilized to run the forming step as an explicit dynamic analysis followed by a static stress analysis using ABAQUS/Standard for calculating the springback. For comparison, results from a complete static stress analysis using ABAQUS/Standard for both the forming and the springback steps are presented.

The import feature in ABAQUS is used for transferring results from ABAQUS/Explicit to ABAQUS/Standard.

The blank is modeled with 4-node, bilinear finite-strain elements (type S4R); while the punch, die, and the blank holder are meshed using 4-node, three-dimensional rigid surface elements (type R3D4). The mesh design for the various parts is shown in Figure 1.5.2–1 and Figure 1.5.2–2.

The blank is held between the blank holders by applying a concentrated load of 22.87 kN. Further loading on the blank is applied by contact forces with the punch in the forming step.

Using ABAQUS/Explicit for the forming procedure involves a single forming step where the rigid punch is pushed against the blank while the blank is held by the blank holders by applying a concentrated load. This description applies to Cases 1a–1e. For the import analysis in ABAQUS/Standard a single step is used to calculate the springback as in Cases 2a–2c. For the complete analysis in ABAQUS/Standard as in Cases 3a and 3b, the following steps are adopted:

First step: the blank holders are brought in contact with the blank by applying a small displacement to the reference point of one of the rigid blank holders.

Second step: a concentrated load is applied to the reference point of the blank holder to hold the blank in place while maintaining contact.

Following steps: the forming is effected by pushing the rigid punch against the blank.

Final two steps: the springback is analyzed by deactivating the contact pairs.

This analysis pertains only to the forming step. For the complete analysis the forming step in this case needs to be followed by a springback analysis (either Case 2a or Case 2b).

General contact is used (see the *CONTACT option and the related suboptions in the input file) to define contact interactions in this case. This allows very simple definitions of contact with very few restrictions on the types of surfaces involved (see “Defining general contact interactions,” Section 29.3.1 of the ABAQUS Analysis User's Manual). However, general contact does not account for changes in shell thickness by default. Consequently, a nondefault option is specified to account for thinning of the blank (see *SURFACE PROPERTY ASSIGNMENT in the input file).

This analysis again pertains only to the forming step. For the complete analysis the forming step needs to be followed by a springback analysis (either Case 2a or Case 2b).

Contact pairs are defined to include blank interaction with the punch, die, and the blank holder separately with appropriate friction behavior as previously specified. The contact pair algorithm, which is specified using the *CONTACT PAIR option, has more restrictions on the types of surfaces involved and often requires more careful definition of contact (see “Defining contact pairs in ABAQUS/Explicit,” Section 29.4.1 of the ABAQUS Analysis User's Manual). Contact interactions are defined between all element-based surfaces in the model.

This analysis pertains only to the forming step. The springback calculations have to be done separately (Case 2a or Case 2b).

In this case the mesh for the blank is uniformly refined so that the number of elements in each direction is twice the number in the previous cases. This case is run to purely benchmark the efficiency of performing an explicit analysis.

In this case the refined mesh defined in Case 1d is utilized for performing the explicit forming analysis.

For running this case, a prior explicit forming analysis (Case 1a, Case 1b, or Case 1c) should have been completed for importing results into ABAQUS/Standard. By setting UPDATE=NO on the *IMPORT option, the displacements are the total values relative to the original reference configuration before the forming analysis. This makes it easy to compare the results with the analysis in which both the forming and springback are analyzed with ABAQUS/Standard.

Similar to Case 2a, a prior explicit forming analysis (Case 1a, Case 1b, or Case 1c) should have been completed for importing results into ABAQUS/Standard. However, using UPDATE=YES on the *IMPORT option implies that the displacements are relative to the deformed configuration at the end of the forming analysis. The boundary conditions and interactions are exactly the same as Case 2a.

For running this case, Case 1d or Case 1e for explicit forming analysis should have been completed for importing results into ABAQUS/Standard. Here again, using UPDATE=YES on the *IMPORT option implies that the displacements are relative to the deformed configuration at the end of the forming analysis. The boundary conditions and interactions are exactly the same as Case 2a.

In this analysis both the forming and the springback steps are analyzed in ABAQUS/Standard.

In this case the surface-to-surface contact formulation is invoked by using *CONTACT PAIR, TYPE=SURFACE. Since double-sided surfaces are not available in ABAQUS/Standard, two single-sided surfaces are used to model the blank when the forming step is modeled in ABAQUS/Standard: one surface to model the top of the blank and one to model the bottom of the blank. The surface-to-surface contact formulation considers the original shell thickness by default throughout the analysis. There is no option to consider the current shell thickness instead of the original shell thickness.

Contact stabilization using *CONTACT CONTROLS, STABILIZE is used to avoid chattering between the blank and the rigid surfaces it is in contact with.

As in Case 3a, both the forming and the springback steps are analyzed in ABAQUS/Standard.

In this case the node-to-surface contact formulation is used. Since, shell thickness cannot be considered by node-to-surface finite-sliding contact, “softened” contact is used to approximate the thickness (see the *SURFACE BEHAVIOR option in the input file).

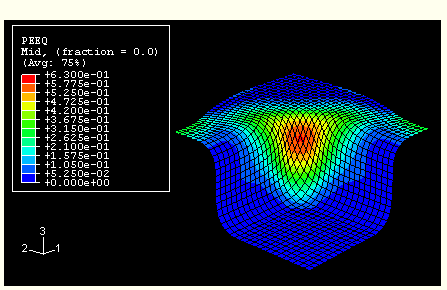

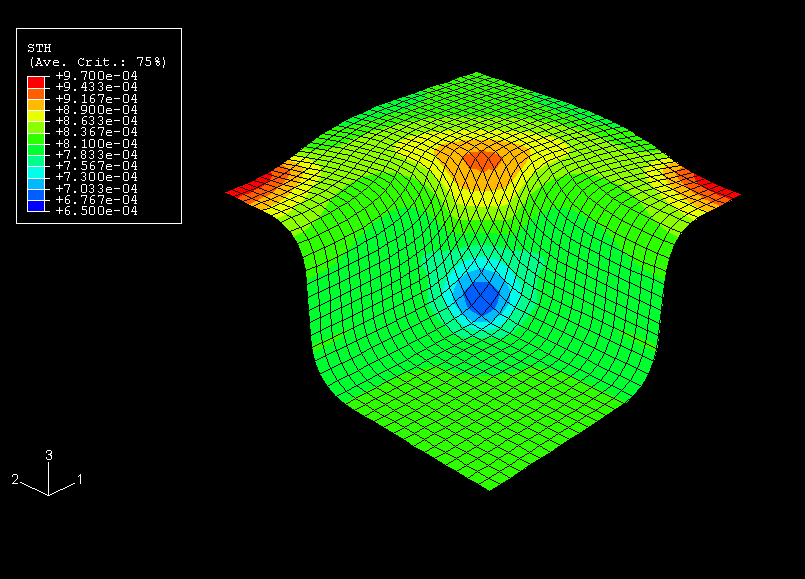

Figure 1.5.2–3, Figure 1.5.2–5, and Figure 1.5.2–4 show contours of shell thickness in the blank at the end of the forming step before springback in ABAQUS/Explicit (Case 1a) and ABAQUS/Standard analyses (Case 3a and Case 3b), respectively. Figure 1.5.2–6, Figure 1.5.2–7, and Figure 1.5.2–8 show contours of equivalent plastic strain in the blank in the final deformed shape for the ABAQUS/Explicit and the two ABAQUS/Standard analyses, respectively. The predicted results are very similar. The ABAQUS/Explicit results match the surface-to-surface contact formulation in ABAQUS/Standard more closely than the node-to-surface results in ABAQUS/Standard. This observation is true for both the equivalent plastic strain contours and shell thickness contours and is a consequence of the intrinsic differences between the various contact formulations. The node-to-surface formulation in ABAQUS/Standard accounts for the shell thickness indirectly by using carefully specified pressure-overclosure relationships (soft contact). The other analyses use contact formulations that account for shell thickness directly. Despite the fact that the surface-to-surface formulation in ABAQUS/Standard uses the original shell thickness throughout the analysis, the results correlate well.

Closer inspection of the results reveals that the corners of the box are formed by stretching, whereas the sides are formed by drawing action. This effect leads to the formation of shear bands that run diagonally across the sides of the box, resulting in a nonhomogeneous wall thickness. The material draws unevenly from the originally straight sides of the blank. Applying a more localized restraint near the midedges of the box (for example, by applying drawbeads) and relaxing the restraint near the corners of the box is expected to increase the quality of the formed product.

Figure 1.5.2–9 shows the reaction force on the punch, and Figure 1.5.2–10 shows the thinning of an element at the corner of the box. Here again, the results from the surface-to-surface formulation in ABAQUS/Standard match those from ABAQUS/Explicit better than the node-to-surface contact formulation in ABAQUS/Standard. In spite of the approximate treatment of surface thickness via the pressure-overclosure relationship for the node-to-surface formulation, the shell thicknesses predicted by ABAQUS/Explicit and the node-to-surface formulation in ABAQUS/Standard differ only by about 4%, reflecting the overall quality of the results.

The springback analysis runs in 6 increments for both of the contact formulations in ABAQUS/Standard. Most of the springback occurs in the z-direction, and the springback is not significant. The corner of the outside edge of the formed box drops approximately 0.35 mm, while the vertical side of the box rises by approximately 0.26 mm. Figure 1.5.2–11 shows a contour plot of the displacements in the z-direction obtained from the springback analysis using the node-to-surface formulation.

The analysis with UPDATE=NO on the *IMPORT option yields similar results. However, in this case the displacements are interpreted as total values relative to the original configuration.

Input file for the explicit forming step.

Input file for the explicit forming step.

Input file for the explicit forming step.

Input file for the explicit forming step.

Input file for the explicit forming step.

Input file for the static springback step.

Input file for the static springback step.

Input file for the static springback step with a refined mesh for the blank.

Input file for the complete static analysis.

Input file for the complete static analysis.

Figure 1.5.2–4 Contours of shell thickness with ABAQUS/Standard using surface-to-surface contact formulation.

Figure 1.5.2–5 Contours of shell thickness with ABAQUS/Standard using node-to-surface contact formulation.

Figure 1.5.2–7 Contours of equivalent plastic strain with ABAQUS/Standard using surface-to-surface contact formulation.