Products: ABAQUS/Standard ABAQUS/Explicit

Mesh:

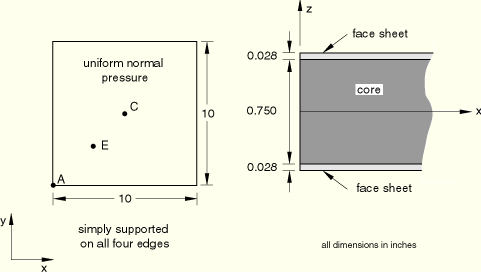

One-quarter model with a 4 × 4 mesh of composite S8R elements in ABAQUS/Standard, an 8 × 8 mesh of composite S4R elements in ABAQUS/Explicit, and an 8 × 8 mesh of continuum shell elements in ABAQUS/Standard. Two types of continuum shell models are provided: (1) a single composite element and (2) three single-layer elements stacked in the thickness direction.

Material:Face sheets: ![]() = 1.0 × 107 psi,

= 1.0 × 107 psi, ![]() = 4.0 × 106 psi,

= 4.0 × 106 psi, ![]() = 0.3,

= 0.3, ![]() = 1.875 × 106 psi,

= 1.875 × 106 psi, ![]() = 1.875 × 106 psi,

= 1.875 × 106 psi, ![]() = 1.875 × 106 psi

= 1.875 × 106 psi

Core: ![]() = 10.0 psi,

= 10.0 psi, ![]() = 10.0 psi,

= 10.0 psi, ![]() = 0,

= 0, ![]() = 10.0 psi,

= 10.0 psi, ![]() = 3.0E4 psi,

= 3.0E4 psi, ![]() = 1.2E4 psi.

= 1.2E4 psi.

Boundary conditions:

Simply supported on all four edges. The continuum shell models use an equation constraint to provide an equivalent midsurface constraint.

Loading:

Uniform normal pressure of 100 psi.

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test R0031/3 from NAFEMS publication R0031, “Composites Benchmarks,” February 1995.

The results are given in Table 4.9.3–1 and Table 4.9.3–2. The values enclosed in parentheses are percentage differences with respect to the reference solution. The displacements reported for the stacked continuum shell model are the average displacements of the bottom and top skins. Due to the soft core, significant pinching is observed.

Table 4.9.3–1 ABAQUS/Standard analysis.

| Model | ||||

|---|---|---|---|---|

| NAFEMS | –0.123 | 34449 | 13932 | –5068 |

| S8R | –0.122 (0.6%) | 36272 (5.3%) | 14125 (5.8%) | –5397 (6.4%) |

| Composite SC6R | –0.120 (–2.4%) | 34687 (0.7%) | 13675 (–1.8%) | –5132 (2.5%) |

| Stacked SC6R | –0.129 (4.8%) | 35382 (2.7%) | 13745 (–1.3%) | –5219 (3.0%) |

| Composite SC8R | –0.122 (–0.8%) | 35312 (2.5%) | 13805 (–0.9%) | –5237 (3.3%) |

| Stacked SC8R | –0.131(6.5%) | 36423 (5.7%) | 14009 (0.6%) | –5360 (5.8%) |

Table 4.9.3–2 ABAQUS/Explicit analysis.

| Model | ||||

|---|---|---|---|---|

| NAFEMS | –0.123 | 34449 | 13932 | –5068 |

| S4R | –0.135 (9.8%) | 36272 (5.3%) | 13287 (5.8%) | –5696 (12.3%)* |

*Nodal stress value obtained by averaging integration point stress values of all adjoining elements.

S8R elements.

Composite SC6R analysis.

Stacked SC6R analysis.

Composite SC8R analysis.

Stacked SC8R analysis.

S4R elements.