Product: ABAQUS/Standard

Mesh:

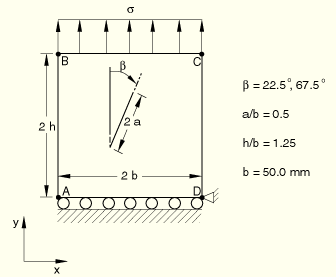

Collapsed elements with 1/4 point midside nodes are used at the crack tip. The complete test geometry is modeled.

Material:Young's modulus = 207 GPa, Poisson's ratio = 0.3.

Boundary conditions:

![]() along edge AD,

along edge AD, ![]() at point D.

at point D.

Loading:

Uniform stress, ![]() = 100 N/mm2.

= 100 N/mm2.

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test 3.1 and 3.2 from NAFEMS publication “2D Test Cases in Linear Elastic Fracture Mechanics,” R0020.

Target solution (![]() = 22.5°): K

= 22.5°): K![]() /K

/K![]() = 0.190, K

= 0.190, K![]() /K

/K![]() = 0.405, K

= 0.405, K![]() =

= ![]()

Target solution (![]() = 67.5°): K

= 67.5°): K![]() /K

/K![]() = 1.030, K

= 1.030, K![]() /K

/K![]() = 0.370, K

= 0.370, K![]() =

= ![]()

The results are shown in the following table. The values enclosed in parentheses are percentage differences with respect to the reference solution.

K![]() =

= ![]() , K

, K![]() = RK

= RK![]() ,

, ![]() .

.

An average of the J values calculated by ABAQUS, excluding the first contour, is used in reporting the results. Experience has shown that the crack-tip elements do not give sufficiently accurate results to give good estimates of the J-integral for the first contour. ![]() and

and ![]() are the displacements of nodes on the positive and negative sides of the crack, respectively, that are initially located at the same position in the undeformed state. An average value for R based on the first five nodal locations behind (not including) the crack tip was used in the calculations.

are the displacements of nodes on the positive and negative sides of the crack, respectively, that are initially located at the same position in the undeformed state. An average value for R based on the first five nodal locations behind (not including) the crack tip was used in the calculations. ![]() and

and ![]() are the tangent and normal, respectively, to the direction of crack propagation.

are the tangent and normal, respectively, to the direction of crack propagation.

CPE8 elements, Test 3.1.

CPE8R elements, Test 3.1.

CPE8 elements, Test 3.2.

CPE8R elements, Test 3.2.