Product: ABAQUS/Standard

Mesh:

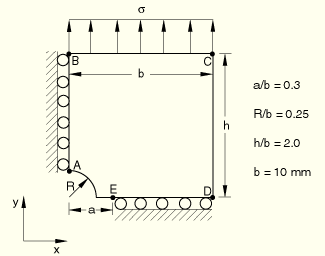

Collapsed elements with 1/4 point midside nodes are used at the crack tip. One-quarter of the test geometry is modeled.

Material:Young's modulus = 207 GPa, Poisson's ratio = 0.3

Boundary conditions:

![]() along edge AB,

along edge AB, ![]() along edge ED.

along edge ED.

Loading:

Uniform stress, ![]() = 100 N/mm2.

= 100 N/mm2.

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test 4.1 and 4.2 from NAFEMS publication “2D Test Cases in Linear Elastic Fracture Mechanics,” R0020.

Target solution: K![]() /K

/K![]() = 1.050, K

= 1.050, K![]() =

= ![]()

The results are shown in the following table. The values enclosed in parentheses are percentage differences with respect to the reference solution.

K![]() =

= ![]() .

. ![]() for plane stress,

for plane stress, ![]() for plane strain. An average of the J values calculated by ABAQUS, excluding the first contour, is used in reporting the results. Experience has shown that the crack-tip elements do not give sufficiently accurate results to give good estimates of the J-integral for the first contour.

for plane strain. An average of the J values calculated by ABAQUS, excluding the first contour, is used in reporting the results. Experience has shown that the crack-tip elements do not give sufficiently accurate results to give good estimates of the J-integral for the first contour.

CPE8 elements.

CPE8R elements.

CPS8 elements.

CPS8R elements.