Products: ABAQUS/Standard ABAQUS/Explicit ABAQUS/CAE

“Defining a pressure load,” Section 16.9.3 of the ABAQUS/CAE User's Manual

“Defining a shell edge load,” Section 16.9.4 of the ABAQUS/CAE User's Manual

“Defining a surface traction load,” Section 16.9.5 of the ABAQUS/CAE User's Manual

“Defining a pipe pressure load,” Section 16.9.6 of the ABAQUS/CAE User's Manual

“Defining a body force,” Section 16.9.7 of the ABAQUS/CAE User's Manual

“Defining a line load,” Section 16.9.8 of the ABAQUS/CAE User's Manual

“Defining a gravity load,” Section 16.9.9 of the ABAQUS/CAE User's Manual

“Defining a rotational body force,” Section 16.9.11 of the ABAQUS/CAE User's Manual

Distributed loads:

can be prescribed on element faces, element bodies, or element edges;

can be prescribed over geometric surfaces or geometric edges; and

require that an appropriate distributed load type be specified—see Part V, “Elements,” for definitions of the distributed load types available for particular elements.

In steady-state dynamic analysis both real and imaginary distributed loads can be applied (see “Direct-solution steady-state dynamic analysis,” Section 6.3.4, and “Mode-based steady-state dynamic analysis,” Section 6.3.8, for details).

Incident wave loading is used to apply distributed loads for the special case of loads associated with a wave traveling through an acoustic medium. Inertia relief is used to apply inertia-based loading in ABAQUS/Standard. These load types are discussed in “Acoustic loads,” Section 19.4.5, and “Inertia relief,” Section 7.4.1, respectively. ABAQUS/Aqua load types are discussed in “ABAQUS/Aqua analysis,” Section 6.10.1.

The prescribed magnitude of a distributed load can vary with time during a step according to an amplitude definition, as described in “Prescribed conditions: overview,” Section 19.1.1. If different variations are needed for different loads, each load can refer to its own amplitude definition.

Distributed loads can be added, modified, or removed as described in “Applying loads: overview,” Section 19.4.1.

In large-displacement analyses in ABAQUS/Standard some distributed load types introduce unsymmetric load stiffness matrix terms. Examples are hydrostatic pressure, pressure applied to surfaces with free edges, Coriolis force, rotary acceleration force, and distributed edge loads and surface tractions modeled as follower loads. In such cases using the unsymmetric matrix storage and solution scheme for the analysis step may improve the convergence rate of the equilibrium iterations. See “Procedures: overview,” Section 6.1.1, for more information on the unsymmetric matrix storage and solution scheme.

Nonuniform distributed loads such as a nonuniform body force in the ![]() -direction can be defined by means of user subroutine DLOAD in ABAQUS/Standard (see “DLOAD,” Section 25.2.5) or VDLOAD in ABAQUS/Explicit (see “VDLOAD,” Section 25.3.1). When an amplitude reference is used with a nonuniform load defined in user subroutine VDLOAD, the current value of the amplitude function is passed to the user subroutine at each time increment in the analysis. DLOAD and VDLOAD are not available for surface tractions, edge tractions, or edge moments.

-direction can be defined by means of user subroutine DLOAD in ABAQUS/Standard (see “DLOAD,” Section 25.2.5) or VDLOAD in ABAQUS/Explicit (see “VDLOAD,” Section 25.3.1). When an amplitude reference is used with a nonuniform load defined in user subroutine VDLOAD, the current value of the amplitude function is passed to the user subroutine at each time increment in the analysis. DLOAD and VDLOAD are not available for surface tractions, edge tractions, or edge moments.

In ABAQUS/Standard nonuniform distributed surface tractions, edge tractions, and edge moments can be defined by means of user subroutine UTRACLOAD (see “UTRACLOAD,” Section 25.2.41). User subroutine UTRACLOAD allows you to define a nonuniform magnitude for surface tractions, edge tractions, and edge moments, as well as nonuniform loading directions for general surface tractions, shear tractions, and general edge tractions.

Nonuniform distributed surface tractions, edge tractions, and edge moments are not currently supported in ABAQUS/Explicit.

As discussed in “Applying loads: overview,” Section 19.4.1, distributed loads can be defined as element-based or surface-based. Element-based distributed loads can be prescribed on element bodies, element surfaces, or element edges. Surface-based distributed loads can be prescribed directly on geometric surfaces or geometric edges.

Three types of distributed loads can be defined: body loads, surface loads, and edge loads. Distributed body loads are always element-based. Distributed surface loads and distributed edge loads can be element-based or surface-based. In ABAQUS/CAE distributed surface and edge loads are always surface-based; surfaces can be defined as collections of geometric faces and edges or collections of element faces and edges. Table 19.4.3–1 summarizes the regions on which each load type can be prescribed. In ABAQUS/CAE all distributed loads are specified by selecting the region in the viewport or from a list of surfaces. In the ABAQUS input file different options are used depending on the type of region to which the load is applied, as illustrated in the following sections.

Table 19.4.3–1 Regions on which the different load types can be prescribed.

| Load type | Load definition | Input file region | ABAQUS/CAE region |

|---|---|---|---|

| Body loads | Element-based | Element bodies | Volumetric bodies |

| Surface loads | Element-based | Element surfaces | N/A |

| Surface-based | Geometric element-based surfaces | Surfaces defined as collections of geometric faces or collections of element faces | |

| Edge loads (including beam line loads) | Element-based | Element edges | N/A |

| Surface-based | Geometric edge-based surfaces | Surfaces defined as collections of geometric edges or collections of element edges |

Body loads, such as gravity, centrifugal, Coriolis, and rotary acceleration loads, are applied as element-based loads. The units of a body force are force per unit volume.

Table 19.4.3–2 lists all of the distributed body load types that are available in ABAQUS, along with the corresponding load type labels.

Table 19.4.3–2 Distributed body load types.

| Load description | Load type label for element-based loads | Load type label for surface-based loads | ABAQUS/CAE load type |

|---|---|---|---|

| Uniform body force in global | BX, BY, BZ | N/A | Body force |

| Nonuniform body force in global | BXNU, BYNU, BZNU | N/A | |

| Uniform body force in radial and axial directions (only for axisymmetric elements) | BR, BZ | N/A | |

| Nonuniform body force in radial and axial directions (only for axisymmetric elements) | BRNU, BZNU | N/A | |

| Gravity loading | GRAV | N/A | Gravity |

| Centrifugal load (magnitude is input as | CENT | N/A | Not supported |

| Centrifugal load (magnitude is input as | CENTRIF | N/A | Rotational body force |

| Coriolis force | CORIO | N/A | Not supported |

| Rotary acceleration load | ROTA | N/A | Rotational body force |

You can specify body forces on any elements in the global ![]() -,

-, ![]() -, or

-, or ![]() -direction. You can specify body forces on axisymmetric elements in the radial or axial direction.

-direction. You can specify body forces on axisymmetric elements in the radial or axial direction.

| Input File Usage: | Use the following option to define a body force in the global |

*DLOAD element number or element set, load type label, magnitude where load type label is BX, BY, BZ, BXNU, BYNU, or BZNU. Use the following option to define a body force in the radial or axial direction on axisymmetric elements: *DLOAD element number or element set, load type label, magnitude where load type label is BR, BZ, BRNU, or BZNU. |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Body force for the Types for Selected Step |

Gravity loading (uniform acceleration in a fixed direction) is specified by using the gravity distributed load type and giving the gravity constant as the magnitude of the load. The direction of the gravity field is specified by giving the components of the gravity vector in the distributed load definition. ABAQUS uses the user-specified material density (see “Density,” Section 9.2.1), together with the magnitude and direction, to calculate the loading. The magnitude of the gravity load can vary with time during a step according to an amplitude definition, as described in “Prescribed conditions: overview,” Section 19.1.1. However, the direction of the gravity field is always applied at the beginning of the step and remains fixed during the step.

You need not specify an element or an element set as is customary for the specification of other distributed loads. ABAQUS automatically collects all elements in the model that have mass contributions (including point mass elements) in an element set called _Whole_Model_Gravity_Elset and applies the gravity loads to the elements in this element set.

When gravity loading is used with substructures, the density must be defined and unit gravity load vectors must be calculated when the substructure is created (see “Defining substructures,” Section 7.2.2).

| Input File Usage: | Use the following option to define a gravity load: |

*DLOAD element number or element set, GRAV, gravity constant, comp1, comp2, comp3 |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Gravity for the Types for Selected Step |

Centrifugal loads, Coriolis forces, and rotary acceleration loads can be applied in ABAQUS/Standard by specifying the appropriate distributed load type in an element-based distributed load definition.

Centrifugal load magnitudes can be specified as ![]() , where

, where ![]() is the angular velocity in radians per time. ABAQUS/Standard uses the specified material density (see “Density,” Section 9.2.1), together with the load magnitude and the axis of rotation, to calculate the loading. Alternatively, a centrifugal load magnitude can be given as

is the angular velocity in radians per time. ABAQUS/Standard uses the specified material density (see “Density,” Section 9.2.1), together with the load magnitude and the axis of rotation, to calculate the loading. Alternatively, a centrifugal load magnitude can be given as ![]() , where

, where ![]() is the material density (mass per unit volume) for solid or shell elements or the mass per unit length for beam elements and

is the material density (mass per unit volume) for solid or shell elements or the mass per unit length for beam elements and ![]() is the angular velocity in radians per time. This type of centrifugal load formulation does not account for large volume changes. The two centrifugal load types will produce slightly different local results for first-order elements;

is the angular velocity in radians per time. This type of centrifugal load formulation does not account for large volume changes. The two centrifugal load types will produce slightly different local results for first-order elements; ![]() uses a consistent mass matrix, and

uses a consistent mass matrix, and ![]() uses a lumped mass matrix in calculating the load forces and load stiffnesses.

uses a lumped mass matrix in calculating the load forces and load stiffnesses.

The magnitude of the centrifugal load can vary with time during a step according to an amplitude definition, as described in “Prescribed conditions: overview,” Section 19.1.1. However, the position and orientation of the axis around which the structure rotates, which is defined by giving a point on the axis and the axis direction, are always applied at the beginning of the step and remain fixed during the step.

| Input File Usage: | Use either of the following options to define a centrifugal load: |

*DLOAD element number or element set, CENTRIF, |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Rotational body force for the Types for Selected Step: Load effect: Centrifugal |

Coriolis force is defined by specifying the Coriolis distributed load type and giving the load magnitude as ![]() , where

, where ![]() is the material density (mass per unit volume) for solid and shell elements or the mass per unit length for beam elements and

is the material density (mass per unit volume) for solid and shell elements or the mass per unit length for beam elements and ![]() is the angular velocity in radians per time. The magnitude of the Coriolis load can vary with time during a step according to an amplitude definition, as described in “Prescribed conditions: overview,” Section 19.1.1. However, the position and orientation of the axis around which the structure rotates, which is defined by giving a point on the axis and the axis direction, are always applied at the beginning of the step and remain fixed during the step.

is the angular velocity in radians per time. The magnitude of the Coriolis load can vary with time during a step according to an amplitude definition, as described in “Prescribed conditions: overview,” Section 19.1.1. However, the position and orientation of the axis around which the structure rotates, which is defined by giving a point on the axis and the axis direction, are always applied at the beginning of the step and remain fixed during the step.

The Coriolis load formulation does not account for large volume changes.

| Input File Usage: | Use the following option to define a Coriolis load: |

*DLOAD element number or element set, CORIO, |

| ABAQUS/CAE Usage: | Coriolis loading is not supported in ABAQUS/CAE. |

Rotary acceleration loads are defined by specifying the rotary acceleration distributed load type and giving the rotary acceleration magnitude, ![]() , in radians/time2, which includes any precessional motion effects. The axis of rotary acceleration must be defined by giving a point on the axis and the axis direction. ABAQUS/Standard uses the specified material density (see “Density,” Section 9.2.1), together with the rotary acceleration magnitude and axis of rotary acceleration, to calculate the loading. The magnitude of the load can vary with time during a step according to an amplitude definition, as described in “Prescribed conditions: overview,” Section 19.1.1. However, the position and orientation of the axis around which the structure rotates are always applied at the beginning of the step and remain fixed during the step.

, in radians/time2, which includes any precessional motion effects. The axis of rotary acceleration must be defined by giving a point on the axis and the axis direction. ABAQUS/Standard uses the specified material density (see “Density,” Section 9.2.1), together with the rotary acceleration magnitude and axis of rotary acceleration, to calculate the loading. The magnitude of the load can vary with time during a step according to an amplitude definition, as described in “Prescribed conditions: overview,” Section 19.1.1. However, the position and orientation of the axis around which the structure rotates are always applied at the beginning of the step and remain fixed during the step.

Rotary acceleration loads are not applicable to axisymmetric elements.

| Input File Usage: | Use the following option to define a rotary acceleration load: |

*DLOAD element number or element set, ROTA, |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Rotational body force for the Types for Selected Step: Load effect: Rotary acceleration |

General or shear surface tractions and pressure loads can be applied in ABAQUS as element-based or surface-based distributed loads. The units of these loads are force per unit area.

Table 19.4.3–3 lists all of the distributed surface load types that are available in ABAQUS, along with the corresponding load type labels.

Table 19.4.3–3 Distributed surface load types.

| Load description | Load type label for element-based loads | Load type label for surface-based loads | ABAQUS/CAE load type |

|---|---|---|---|

| Uniform general surface traction | TRVECn | TRVEC | Surface traction |

| Uniform shear surface traction | TRSHRn | TRSHR | |

| Nonuniform general surface traction | TRVECnNU | TRVECNU | Not supported |

| Nonuniform shear surface traction | TRSHRnNU | TRSHRNU | |

| Uniform pressure | Pn | P | Pressure |

| Nonuniform pressure | PnNU | PNU | |

| Hydrostatic pressure (available only in ABAQUS/Standard) | HPn | HP | |

| Hydrostatic internal and external pressure (only for PIPE elements in ABAQUS/Standard) | HPI, HPE | N/A | Pipe pressure |

| Uniform internal and external pressure (only for PIPE elements in ABAQUS/Standard) | PI, PE | N/A | |

| Nonuniform internal and external pressure (only for PIPE elements in ABAQUS/Standard) | PINU, PENU | N/A | |

| Viscous pressure (available only in ABAQUS/Explicit) | VPn | VP | Not supported |

By definition, the line of action of a follower surface load rotates with the surface in a geometrically nonlinear analysis. This is in contrast to a non-follower load, which always acts in a fixed global direction.

With the exception of general surface tractions, all the distributed surface loads listed in Table 19.4.3–3 are modeled as follower loads. The hydrostatic and viscous pressures listed in Table 19.4.3–3 always act normal to the surface in the current configuration, the shear tractions always act tangent to the surface in the current configuration, and the internal and external pipe pressures follow the motion of the pipe elements.

General surface tractions can be specified to be follower or non-follower loads. There is no difference between a follower and a non-follower load in a geometrically linear analysis since the configuration of the body remains fixed. The difference between a follower and non-follower general surface traction is illustrated in the next section through an example.

| Input File Usage: | Use one of the following options to define general surface tractions as follower loads (the default): |

*DLOAD, FOLLOWER=YES *DSLOAD, FOLLOWER=YES Use one of the following options to define general surface tractions as non-follower loads: *DLOAD, FOLLOWER=NO *DSLOAD, FOLLOWER=NO |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Shell edge load or Surface traction for the Types for Selected Step: Traction: General: toggle on or off Follow rotation |

General surface tractions allow you to specify a surface traction, ![]() , acting on a surface

, acting on a surface ![]() . The resultant load,

. The resultant load, ![]() , is computed by integrating

, is computed by integrating ![]() over

over ![]() :

:

![]()

![]()

| Input File Usage: | Use one of the following options to define a general surface traction: |

*DLOAD element number or element set, TRVECn or TRVECnNU, magnitude, direction components *DSLOAD surface name, TRVEC or TRVECNU, magnitude, direction components |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Surface traction for the Types for Selected Step: Traction: General |

By default, the components of the traction vector are specified with respect to the global directions. You can also refer to a local coordinate system (see “Orientations,” Section 2.2.5) for the direction components of these tractions. See “Examples: using a local coordinate system to define shear directions” below for an example of a traction load defined with respect to a local coordinate system.

| Input File Usage: | Use one of the following options to specify a local coordinate system: |

*DLOAD, ORIENTATION=name *DSLOAD, ORIENTATION=name |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Surface traction or Shell edge load for the Types for Selected Step: select CSYS: Picked and click Edit to pick a local coordinate system, or select CSYS: User-defined to enter the name of a user subroutine that defines a local coordinate system |

The traction load acts in the fixed direction ![]() in a geometrically linear analysis or if a non-follower load is specified in a geometrically nonlinear analysis (which includes a perturbation step about a geometrically nonlinear base state).

in a geometrically linear analysis or if a non-follower load is specified in a geometrically nonlinear analysis (which includes a perturbation step about a geometrically nonlinear base state).

If a follower load is specified in a geometrically nonlinear analysis, the traction load rotates rigidly with the surface using the following algorithm. The reference configuration traction vector, ![]() , is decomposed by ABAQUS into two components: a normal component,

, is decomposed by ABAQUS into two components: a normal component,

![]()

![]()

![]()

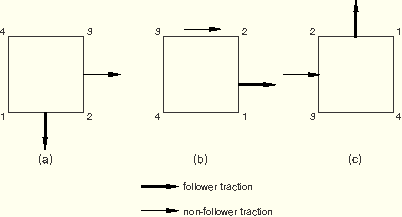

The following two examples illustrate the difference between applying follower and non-follower tractions in a geometrically nonlinear analysis. Both examples refer to a single 4-node plane strain element (element 1). In Step 1 of the first example a follower traction load is applied to face 1 of element 1, and a non-follower traction load is applied to face 2 of element 1. The element is rotated rigidly 90° counterclockwise in Step 1 and then another 90° in Step 2. As illustrated in Figure 19.4.3–1, the follower traction rotates with face 1, while the non-follower traction on face 2 always acts in the global ![]() -direction.

-direction.

Figure 19.4.3–1 Follower and non-follower traction loads in a geometrically nonlinear analysis, load applied in Step 1: (a) beginning of Step 1; (b) end of Step 1, beginning of Step 2; (c) end of Step 2.

*STEP, NLGEOM Step 1 - Rotate square 90 degrees ... *DLOAD, FOLLOWER=YES 1, TRVEC1, 1., 0., -1., 0. *DLOAD, FOLLOWER=NO 1, TRVEC2, 1., 1., 0., 0. *END STEP *STEP, NLGEOM Step 2 - Rotate square another 90 degrees ... *END STEP

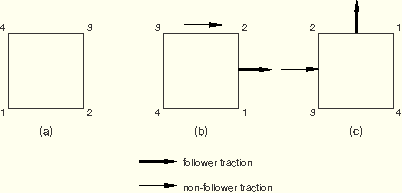

In the second example the element is rotated 90° counterclockwise with no load applied in Step 1. In Step 2 a follower traction load is applied to face 1, and a non-follower traction load is applied to face 2. The element is then rotated rigidly by another 90°. The direction of the follower load is specified with respect to the original configuration. As illustrated in Figure 19.4.3–2, the follower traction rotates with face 1, while the non-follower traction on face 2 always acts in the global ![]() -direction.

-direction.

Figure 19.4.3–2 Follower and non-follower traction loads in a geometrically nonlinear analysis, load applied in Step 2: (a) beginning of Step 1; (b) end of Step 1, beginning of Step 2; (c) end of Step 2.

*STEP, NLGEOM Step 1 - Rotate square 90 degrees ... *END STEP *STEP, NLGEOM Step 2 - Rotate square another 90 degrees *DLOAD, FOLLOWER=YES 1, TRVEC1, 1., 0., -1., 0. *DLOAD, FOLLOWER=NO 1, TRVEC2, 1., 1., 0., 0. ... *END STEP

Shear surface tractions allow you to specify a surface force per unit area, ![]() , that acts tangent to a surface

, that acts tangent to a surface ![]() . The resultant load,

. The resultant load, ![]() , is computed by integrating

, is computed by integrating ![]() over

over ![]() :

:

![]()

ABAQUS computes the traction direction ![]() by first projecting the user-specified vector,

by first projecting the user-specified vector, ![]() , onto the surface in the reference configuration,

, onto the surface in the reference configuration,

![]()

![]()

The shear traction load acts in the fixed direction ![]() in a geometrically linear analysis. In a geometrically nonlinear analysis (which includes a perturbation step about a geometrically nonlinear base state), the shear traction vector will rotate rigidly; i.e.,

in a geometrically linear analysis. In a geometrically nonlinear analysis (which includes a perturbation step about a geometrically nonlinear base state), the shear traction vector will rotate rigidly; i.e., ![]() , where

, where ![]() is the standard rotation tensor obtained from the polar decomposition of the local two-dimensional surface deformation gradient

is the standard rotation tensor obtained from the polar decomposition of the local two-dimensional surface deformation gradient ![]() .

.

| Input File Usage: | Use one of the following options to define a shear surface traction: |

*DLOAD element number or element set, TRSHRn or TRSHRnNU, magnitude, direction components *DSLOAD surface name, TRSHR or TRSHRNU, magnitude, direction components |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Surface traction for the Types for Selected Step: Traction: Shear |

By default, the components of the shear traction vector are specified with respect to the global directions. You can also refer to a local coordinate system (see “Orientations,” Section 2.2.5) for the direction components of these tractions.

| Input File Usage: | Use one of the following options to specify a local coordinate system: |

*DLOAD, ORIENTATION=name *DSLOAD, ORIENTATION=name |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Surface traction or Shell edge load for the Types for Selected Step: select CSYS: Picked and click Edit to pick a local coordinate system, or select CSYS: User-defined to enter the name of a user subroutine that defines a local coordinate system |

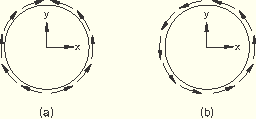

It is sometimes convenient to give shear and general traction directions with respect to a local coordinate system. The following two examples illustrate the specification of the direction of a shear traction on a cylinder using global coordinates in one case and a local cylindrical coordinate system in the other case. The axis of symmetry of the cylinder coincides with the global ![]() -axis. A surface named SURFA has been defined on the outside of the cylinder.

-axis. A surface named SURFA has been defined on the outside of the cylinder.

In the first example the direction of the shear traction, ![]() , is given in global coordinates. The sense of the resulting shear tractions using global coordinates is shown in Figure 19.4.3–3(a).

, is given in global coordinates. The sense of the resulting shear tractions using global coordinates is shown in Figure 19.4.3–3(a).

Figure 19.4.3–3 Shear tractions specified using global coordinates (a) and a local cylindrical coordinate system (b).

*STEP Step 1 - Specify shear directions in global coordinates ... *DSLOAD SURFA, TRSHR, 1., 0., 1., 0. ... *END STEP

In the second example the direction of the shear traction, ![]() , is given with respect to a local cylindrical coordinate system whose axis coincides with the axis of the cylinder. The sense of the resulting shear tractions using the local cylindrical coordinate system is shown in Figure 19.4.3–3(b).

, is given with respect to a local cylindrical coordinate system whose axis coincides with the axis of the cylinder. The sense of the resulting shear tractions using the local cylindrical coordinate system is shown in Figure 19.4.3–3(b).

*ORIENTATION, NAME=CYLIN, SYSTEM=CYLINDRICAL 0., 0., 0., 0., 0., 1. ... *STEP Step 1 - Specify shear directions in local cylindrical coordinates ... *DSLOAD, ORIENTATION=CYLIN SURFA, TRSHR, 1., 0., 1., 0. ... *END STEP

You can choose to integrate surface tractions over the current or the reference configuration by specifying whether or not a constant resultant should be maintained.

In general, the constant resultant method is best suited for cases where the magnitude of the resultant load should not vary with changes in the surface area. However, it is up to you to decide which approach is best for your analysis. An example of an analysis using a constant resultant can be found in “Distributed traction and edge loads,” Section 1.4.17 of the ABAQUS Verification Manual.

If you choose not to have a constant resultant, the traction vector is integrated over the surface in the current configuration, a surface that in general deforms in a geometrically nonlinear analysis. By default, all surface tractions are integrated over the surface in the current configuration.

| Input File Usage: | Use one of the following options: |

*DLOAD, CONSTANT RESULTANT=NO *DSLOAD, CONSTANT RESULTANT=NO |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Surface traction for the Types for Selected Step: Traction is defined per unit deformed area |

If you choose to have a constant resultant, the traction vector is integrated over the surface in the reference configuration, which is constant.

| Input File Usage: | Use one of the following options: |

*DLOAD, CONSTANT RESULTANT=YES *DSLOAD, CONSTANT RESULTANT=YES |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Surface traction for the Types for Selected Step: Traction is defined per unit undeformed area |

The constant resultant method has certain advantages when a traction is used to model a distributed load with a known constant resultant. Consider the case of modeling a uniform dead load, magnitude ![]() , acting on a flat plate whose normal is in the

, acting on a flat plate whose normal is in the ![]() -direction in a geometrically nonlinear analysis (Figure 19.4.3–4).

-direction in a geometrically nonlinear analysis (Figure 19.4.3–4).

![]()

![]()

Distributed pressure loads can be specified on any elements. Hydrostatic pressure loads can be specified in ABAQUS/Standard on two-dimensional, three-dimensional, and axisymmetric elements. Viscous pressure loads can be specified in ABAQUS/Explicit on any elements.

Distributed pressure loads can be specified on any elements.

| Input File Usage: | Use one of the following options to define a pressure load: |

*DLOAD element number or element set, Pn or PnNU, magnitude *DSLOAD surface name, P or PNU, magnitude |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Pressure for the Types for Selected Step: Distribution: Uniform |

To define hydrostatic pressure in ABAQUS/Standard, give the ![]() -coordinates of the zero pressure level (point

-coordinates of the zero pressure level (point ![]() in Figure 19.4.3–5) and the level at which the hydrostatic pressure is defined (point

in Figure 19.4.3–5) and the level at which the hydrostatic pressure is defined (point ![]() in Figure 19.4.3–5) in an element-based or surface-based distributed load definition. For levels above the zero pressure level, the hydrostatic pressure is zero.

in Figure 19.4.3–5) in an element-based or surface-based distributed load definition. For levels above the zero pressure level, the hydrostatic pressure is zero.

In planar elements the hydrostatic head is in the ![]() -direction; for axisymmetric elements the

-direction; for axisymmetric elements the ![]() -direction is the second coordinate.

-direction is the second coordinate.

| Input File Usage: | Use one of the following options to define a hydrostatic pressure load: |

*DLOAD element number or element set, HPn, magnitude, |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Pressure for the Types for Selected Step: Distribution: Hydrostatic |

You can specify external pressure, internal pressure, external hydrostatic pressure, or internal hydrostatic pressure on pipe or elbow elements. When pressure loads are applied, the effective outer or inner diameter must be specified in the element-based distributed load definition.

By default, the loads resulting from the pressure on the ends of the element are included: ABAQUS/Standard assumes a closed-end condition. Open-end loading can be specified in the element-based distributed load definition.

Closed-end conditions should be used in all but exceptional cases. Closed-end conditions correctly model the loading at pipe intersections, tight bends, corners, and cross-section changes; whereas open-end conditions require application of additional loads at such points. In straight sections and smooth bends the end loads of adjacent elements cancel each other precisely. The only case where closed-end conditions yield an incorrect end load occurs if the pressure at the end of a pipe is supported by an independent structure (such as a piston), which is rather unusual. An incorrect end load is also generated if a pressurized pipe is modeled with a mixture of pipe and beam elements. In that case closed-end conditions generate a physically non-existing force at the transition between pipe and beam elements. Such mixed modeling of a pipe is not recommended. Although open-end conditions can be used to eliminate incorrect end loads in these cases, it is usually better to use closed-end conditions in all pipe elements and to compensate for any unwanted end loads with explicitly defined nodal loads.

For pipe elements subjected to pressure loading, the effective axial force due to the pressure loads can be obtained by requesting output variable ESF1 (see “Beam element library,” Section 15.3.8).

| Input File Usage: | Use the following option to define an external pressure load on pipe or elbow elements: |

*DLOAD element number or element set, PE or PENU, magnitude, effective outer diameter, CLOSE (default) or OPEN Use the following option to define an internal pressure load on pipe or elbow elements: *DLOAD element number or element set, PI or PINU, magnitude, effective inner diameter, CLOSE (default) or OPEN Use the following option to define an external hydrostatic pressure load on pipe or elbow elements: *DLOAD element number or element set, HPE, magnitude, effective outer diameter, CLOSE (default) or OPEN Use the following option to define an internal hydrostatic pressure load on pipe or elbow elements: *DLOAD element number or element set, HPI, magnitude, effective inner diameter, CLOSE (default) or OPEN |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Pipe pressure for the Types for Selected Step |

Viscous pressure loads are defined by

![]()

Viscous pressure loading is most commonly applied in structural problems when you wish to damp out dynamic effects and, thus, reach static equilibrium in a minimal number of increments. A common example is the determination of springback in a sheet metal product after forming, in which case a viscous pressure would be applied to the faces of shell elements defining the sheet metal. An appropriate choice for the value of ![]() is important for using this technique effectively.

is important for using this technique effectively.

To compute ![]() , consider the infinite continuum elements described in “Infinite elements,” Section 14.2.1. In explicit dynamics those elements achieve an infinite boundary condition by applying a viscous normal pressure where the coefficient

, consider the infinite continuum elements described in “Infinite elements,” Section 14.2.1. In explicit dynamics those elements achieve an infinite boundary condition by applying a viscous normal pressure where the coefficient ![]() is given by

is given by ![]() ;

; ![]() is the density of the material at the surface, and

is the density of the material at the surface, and ![]() is the value of the dilatational wave speed in the material (the infinite continuum elements also apply a viscous shear traction). For an isotropic, linear elastic material

is the value of the dilatational wave speed in the material (the infinite continuum elements also apply a viscous shear traction). For an isotropic, linear elastic material

For typical structural problems it is not desirable to absorb all of the energy (as is the case in the infinite elements). Typically ![]() is set equal to a small percentage (perhaps 1 or 2 percent) of

is set equal to a small percentage (perhaps 1 or 2 percent) of ![]() as an effective way of minimizing ongoing dynamic effects. The

as an effective way of minimizing ongoing dynamic effects. The ![]() coefficient should have a positive value.

coefficient should have a positive value.

| Input File Usage: | Use one of the following options to define a viscous pressure load: |

*DLOAD element number or element set, VPn, magnitude *DSLOAD surface name, VP, magnitude |

| ABAQUS/CAE Usage: | Viscous pressure loads are not supported in ABAQUS/CAE. |

Plane stress theory assumes that the volume of a plane stress element remains constant in a large-strain analysis. When a distributed surface load is applied to an edge of plane stress elements, the current length and orientation of the edge are considered in the load distribution, but the current thickness is not; the original thickness is used.

This limitation can be circumvented only by using three-dimensional elements at the edge so that a change in thickness upon loading is recognized; suitable equation constraints (“Linear constraint equations,” Section 20.2.1) would be required to make the in-plane displacements on the two faces of these elements equal. Three-dimensional elements along an edge can be connected to interior shell elements by using a shell-to-solid coupling constraint (see “Shell-to-solid coupling,” Section 20.3.3, for details).

Distributed edge tractions (general, shear, normal, or transverse) and edge moments can be applied to shell elements in ABAQUS as element-based or surface-based distributed loads. The units of an edge traction are force per unit length. The units of an edge moment are torque per unit length. References to local coordinate systems are ignored for all edge tractions and moments except general edge tractions.

Distributed line loads can be applied to beam elements in ABAQUS as element-based distributed loads. The units of a line load are force per unit length.

Table 19.4.3–4 lists all of the distributed edge and line load types that are available in ABAQUS, along with the corresponding load type labels.

Table 19.4.3–4 Distributed edge load types.

| Load description | Load type label for element-based loads | Load type label for surface-based loads | ABAQUS/CAE load type |

|---|---|---|---|

| Uniform general edge traction | EDLDn | EDLD | Shell edge load |

| Uniform normal edge traction | EDNORn | EDNOR | |

| Uniform shear edge traction | EDSHRn | EDSHR | |

| Uniform transverse edge traction | EDTRAn | EDTRA | |

| Uniform edge moment | EDMOMn | EDMOM | |

| Nonuniform general edge traction | EDLDnNU | EDLDNU | Not supported |

| Nonuniform normal edge traction | EDNORnNU | EDNORNU | |

| Nonuniform shear edge traction | EDSHRnNU | EDSHRNU | |

| Nonuniform transverse edge traction | EDTRAnNU | EDTRANU | |

| Nonuniform edge moment | EDMOMnNU | EDMOMNU | |

| Uniform force per unit length in global | PX, PY, PZ | N/A | Line load |

| Nonuniform force per unit length in global | PXNU, PYNU, PZNU | N/A | |

| Uniform force per unit length in beam local 1- and 2-directions (only for beam elements) | P1, P2 | N/A | |

| Nonuniform force per unit length in beam local 1- and 2-directions (only for beam elements) | P1NU, P2NU | N/A |

By definition, the line of action of a follower edge or line load rotates with the edge or line in a geometrically nonlinear analysis. This is in contrast to a non-follower load, which always acts in a fixed global direction.

With the exception of general edge tractions on shell elements and the forces per unit length in the global directions on beam elements, all the edge and line loads listed in Table 19.4.3–4 are modeled as follower loads. The normal, shear, and transverse edge loads listed in Table 19.4.3–4 act in the normal, shear, and transverse directions, respectively, in the current configuration (see Figure 19.4.3–6).

The edge moment always acts about the shell edge in the current configuration. The forces per unit length in the local beam directions rotate with the beam elements.The forces per unit length in the global directions on beam elements are always non-follower loads.

General edge tractions can be specified to be follower or non-follower loads. There is no difference between a follower and a non-follower load in a geometrically linear analysis since the configuration of the body remains fixed.

| Input File Usage: | Use one of the following options to define general edge tractions as follower loads (the default): |

*DLOAD, FOLLOWER=YES *DSLOAD, FOLLOWER=YES Use one of the following options to define general edge tractions as non-follower loads: *DLOAD, FOLLOWER=NO *DSLOAD, FOLLOWER=NO |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Shell edge load or Surface traction for the Types for Selected Step: Traction: General: toggle on or off Follow rotation |

General edge tractions allow you to specify an edge load, ![]() , acting on a shell edge,

, acting on a shell edge, ![]() . The resultant load,

. The resultant load, ![]() , is computed by integrating

, is computed by integrating ![]() over

over ![]() :

:

![]()

To define a general edge traction, you must provide both a magnitude, ![]() , and direction,

, and direction, ![]() , for the load. The specified load directions are normalized by ABAQUS; thus, they do not contribute to the magnitude of the load.

, for the load. The specified load directions are normalized by ABAQUS; thus, they do not contribute to the magnitude of the load.

If a nonuniform general edge traction is specified, the magnitude, ![]() , and direction,

, and direction, ![]() , must be specified in user subroutine UTRACLOAD.

, must be specified in user subroutine UTRACLOAD.

| Input File Usage: | Use one of the following options to define a general edge traction: |

*DLOAD element number or element set, EDLDn or EDLDnNU, magnitude, direction components *DSLOAD surface name, EDLD or EDLDNU, magnitude, direction components |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Shell edge load for the Types for Selected Step: Traction: General |

In a geometrically linear analysis the edge load, ![]() , acts in the fixed direction defined by

, acts in the fixed direction defined by

![]()

If a non-follower load is specified in a geometrically nonlinear analysis (which includes a perturbation step about a geometrically nonlinear base state), the edge load, ![]() , acts in the fixed direction defined by

, acts in the fixed direction defined by

![]()

If a follower load is specified in a geometrically nonlinear analysis (which includes a perturbation step about a geometrically nonlinear base state), the components must be defined with respect to the reference configuration. The reference edge traction is defined as

![]()

By default, the components of the edge traction vector are specified with respect to the global directions. You can also refer to a local coordinate system (see “Orientations,” Section 2.2.5) for the direction components of these tractions.

| Input File Usage: | Use one of the following options to specify a local coordinate system: |

*DLOAD, ORIENTATION=name *DSLOAD, ORIENTATION=name |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Surface traction or Shell edge load for the Types for Selected Step: select CSYS: Picked and click Edit to pick a local coordinate system, or select CSYS: User-defined to enter the name of a user subroutine that defines a local coordinate system |

The loading directions of shear, normal, and transverse edge tractions are determined by the underlying elements. A positive shear edge traction acts in the positive direction of the shell edge as determined by the element connectivity. A positive normal edge traction acts in the plane of the shell in the inward direction. A positive transverse edge traction acts in a sense opposite to the facet normal. The directions of positive shear, normal, and transverse edge tractions are shown in Figure 19.4.3–6.

To define a shear, normal, or transverse edge traction, you must provide a magnitude, ![]() for the load.

for the load.

If a nonuniform shear, normal, or transverse edge traction is specified, the magnitude, ![]() , must be specified in user subroutine UTRACLOAD.

, must be specified in user subroutine UTRACLOAD.

In a geometrically linear step, the shear, normal, and transverse edge tractions act in the tangential, normal, and transverse directions of the shell, as shown in Figure 19.4.3–6. In a geometrically nonlinear analysis the shear, normal, and transverse edge tractions rotate with the shell edge so they always act in the tangential, normal, and transverse directions of the shell, as shown in Figure 19.4.3–6.

| Input File Usage: | Use one of the following options to define a directed edge traction: |

*DLOAD element number or element set, directed edge traction label, magnitude *DSLOAD surface name, directed edge traction label, magnitude For element-based loads the directed edge traction label can be EDSHRn or EDSHRnNU for shear edge tractions, EDNORn or EDNORnNU for normal edge tractions, or EDTRAn or EDTRAnNU for transverse edge tractions. For surface-based loads the directed edge traction label can be EDSHR or EDSHRNU for shear edge tractions, EDNOR or EDNORNU for normal edge tractions, or EDTRA or EDTRANU for transverse edge tractions. |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Shell edge load for the Types for Selected Step: Traction: Normal, Transverse, or Shear |

An edge moment acts about the shell edge with the positive direction determined by the element connectivity. The directions of positive edge moments are shown in Figure 19.4.3–7.

To define a distributed edge moment, you must provide a magnitude, ![]() , for the load.

, for the load.

If a nonuniform edge moment is specified, the magnitude, ![]() , must be specified in user subroutine UTRACLOAD.

, must be specified in user subroutine UTRACLOAD.

An edge moment always acts about the current shell edge in both geometrically linear and nonlinear analyses.

In a geometrically linear step an edge moment acts about the shell edge as shown in Figure 19.4.3–7. In a geometrically nonlinear analysis an edge moment always acts about the shell edge as shown in Figure 19.4.3–7.

| Input File Usage: | Use one of the following options to define an edge moment: |

*DLOAD element number or element set, EDMOMn or EDMOMnNU, magnitude *DSLOAD surface name, EDMOM or EDMOMNU, magnitude |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Shell edge load for the Types for Selected Step: Traction: Moment |

You can choose to integrate edge tractions and moments over the current or the reference configuration by specifying whether or not a constant resultant should be maintained. In general, the constant resultant method is best suited for cases where the magnitude of the resultant load should not vary with changes in the edge length. However, it is up to you to decide which approach is best for your analysis.

If you choose not to have a constant resultant, an edge traction or moment is integrated over the edge in the current configuration, an edge whose length changes during a geometrically nonlinear analysis.

| Input File Usage: | Use one of the following options: |

*DLOAD, CONSTANT RESULTANT=NO *DSLOAD, CONSTANT RESULTANT=NO |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Shell edge load for the Types for Selected Step: Traction is defined per unit deformed area |

If you choose to have a constant resultant, an edge traction or moment is integrated over the edge in the reference configuration, whose length is constant.

| Input File Usage: | Use one of the following options: |

*DLOAD, CONSTANT RESULTANT=YES *DSLOAD, CONSTANT RESULTANT=YES |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Shell edge load for the Types for Selected Step: Traction is defined per unit undeformed area |

You can specify line loads on beam elements in the global ![]() -,

-, ![]() -, or

-, or ![]() -direction. In addition, you can specify line loads on beam elements in the beam local 1- or 2-direction.

-direction. In addition, you can specify line loads on beam elements in the beam local 1- or 2-direction.

| Input File Usage: | Use the following option to define a force per unit length in the global |

*DLOAD element number or element set, load type label, magnitude where load type label is PX, PY, PZ, PXNU, PYNU, or PZNU. Use the following option to define a force per unit length in the beam local 1- or 2-direction: *DLOAD element number or element set, load type label, magnitude where load type label is P1, P2, P1NU, or P2NU. |

| ABAQUS/CAE Usage: | Load module: Create Load: choose Mechanical for the Category and Line load for the Types for Selected Step |