Products: ABAQUS/Standard ABAQUS/Explicit

The preferred method for defining rebar in shell and membrane elements is defining layers of reinforcement as part of the element section definition (documented in “Defining reinforcement,” Section 2.2.3). The preferred method for defining rebar in solids is embedding reinforced surface or membrane elements in “host” solid elements as described in “Embedded elements,” Section 20.4.1. This section describes an alternative method of defining rebar in shell, membrane, and continuum elements as an element property. This method is more cumbersome than the method described in “Defining reinforcement,” Section 2.2.3, and does not allow visualization of the rebar and rebar results in ABAQUS/CAE.

Element-based rebars:

are used to define uniaxial reinforcement in solid, membrane, and shell elements;

can be defined as individual reinforcing bars in solid elements;

can be defined as layers of uniformly spaced reinforcing bars in shell, membrane, and solid elements (such layers are treated as a smeared layer with a constant thickness equal to the area of each reinforcing bar divided by the reinforcing bar spacing);

can be used with coupled temperature-displacement elements but do not contribute to the thermal conductivity and specific heat;

do not contribute to the mass of the model in ABAQUS/Standard;

cannot be used in elements intended for heat transfer or mass diffusion analysis;

cannot be used with triangular shell and membrane elements or with triangular, triangular prism, and tetrahedral solid elements; and

have material properties that are distinct from those of the underlying element.

You must assign a name to the rebar set. This name can be used in defining rebar prestress and output requests. Each layer of rebar must be assigned a separate name in a particular element or element set.

| Input File Usage: | *REBAR, ELEMENT=elem, MATERIAL=mat, NAME=name |

Both isoparametric and skew rebars can be defined in three-dimensional shell and membrane elements. Rebars cannot be used with triangular shells or membranes.

If triangular-shaped shells or membranes are needed, collapsed quadrilateral shells or membranes can be used. The resulting rebar directions will depend on the type of rebar (isoparametric or skew) used. The rebar must be defined carefully since the element is distorted. This technique should be used only in regions of the mesh where results are not critical and stress gradients are not high.

The stiffness calculations for the rebars use the same integration points as the calculations for the underlying shell or membrane elements. See “Shell elements: overview,” Section 15.6.1, and “Membrane elements,” Section 15.1.1, for more information about shell and membrane elements.

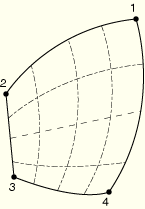

Isoparametric rebars are aligned along the mapping of constant isoparametric lines in the element (see Figure 2.2.4–1).

If opposite edges of the element containing the rebar are not parallel, the rebar directions will be different at each of the integration points within an element (see Figure 2.2.4–2).Figure 2.2.4–2 “Isoparametric” rebar directions in a distorted three-dimensional shell or membrane element (dashed lines indicate rebar directions).

The spacing of the rebar will be fixed in physical space. The spacing, ![]() , and the area of the rebar,

, and the area of the rebar, ![]() , are used to determine the thickness of the equivalent smeared layer,

, are used to determine the thickness of the equivalent smeared layer, ![]() . If the edges of the element containing the rebar are not parallel, the number of actual rebar with this spacing passing through one edge will be different than the number passing through the opposite edge (opposite in isoparametric space).

. If the edges of the element containing the rebar are not parallel, the number of actual rebar with this spacing passing through one edge will be different than the number passing through the opposite edge (opposite in isoparametric space).

You specify the elements that contain the rebars; the cross-sectional area, ![]() , of each rebar; the rebar spacing in the plane of the shell,

, of each rebar; the rebar spacing in the plane of the shell, ![]() ; and the edge number to which the rebars are parallel when plotted in isoparametric space (see Figure 2.2.4–1). In addition, for shell elements you specify the position of the rebars in the shell thickness direction measured from the midsurface of the shell (positive in the direction of the positive normal to the shell). If the shell's thickness is defined by nodal thicknesses (“Nodal thicknesses,” Section 2.1.3), this distance will be scaled by the ratio of the thickness defined by the nodal thickness to the thickness defined by the section definition. If the shell's thickness is defined by an element property assignment (“Assigning element properties on an element-by-element basis,” Section 13.1.5), this distance will be scaled by the ratio of the thickness defined by the element property assignment to the thickness defined by the section definition.

; and the edge number to which the rebars are parallel when plotted in isoparametric space (see Figure 2.2.4–1). In addition, for shell elements you specify the position of the rebars in the shell thickness direction measured from the midsurface of the shell (positive in the direction of the positive normal to the shell). If the shell's thickness is defined by nodal thicknesses (“Nodal thicknesses,” Section 2.1.3), this distance will be scaled by the ratio of the thickness defined by the nodal thickness to the thickness defined by the section definition. If the shell's thickness is defined by an element property assignment (“Assigning element properties on an element-by-element basis,” Section 13.1.5), this distance will be scaled by the ratio of the thickness defined by the element property assignment to the thickness defined by the section definition.

| Input File Usage: | Use the following option to define isoparametric rebars in three-dimensional shell elements: |

*REBAR, ELEMENT=SHELL, MATERIAL=mat, GEOMETRY=ISOPARAMETRIC Use the following option to define isoparametric rebars in general membrane elements: *REBAR, ELEMENT=MEMBRANE, MATERIAL=mat, GEOMETRY=ISOPARAMETRIC |

Skew rebars need not be similar to an element edge; they can lie at any prescribed angle from the local 1-axis. The direction of the rebars must be defined in one of two ways, as indicated in Figure 2.2.4–3:

The rebars can be defined relative to the default projected local coordinate system (see “Conventions,” Section 1.2.2).

The rebars can be defined relative to a user-defined local coordinate system (see “Orientations,” Section 2.2.5).

For shell elements the definition of a local coordinate system using an element property assignment (“Assigning element properties on an element-by-element basis,” Section 13.1.5) has no influence on the rebar angular orientation definitions.

If the rebar cross-sectional area is ![]() , the rebar spacing,

, the rebar spacing, ![]() , should be given so that the thickness of the equivalent “smeared” layer of reinforcing is

, should be given so that the thickness of the equivalent “smeared” layer of reinforcing is ![]() .

.

To define skew rebars relative to the default projected local coordinate system, you specify the elements that contain the rebars; the cross-sectional area, ![]() , of each rebar; the rebar spacing in the plane of the shell,

, of each rebar; the rebar spacing in the plane of the shell, ![]() ; the position of the rebars in the thickness direction (for shell elements only), measured from the midsurface of the shell (positive in the direction of the positive normal to the shell); and the angle

; the position of the rebars in the thickness direction (for shell elements only), measured from the midsurface of the shell (positive in the direction of the positive normal to the shell); and the angle ![]() , in degrees, between the default local 1-direction and the rebars. See “Conventions,” Section 1.2.2, for a definition of the default projected local directions on a surface in space. If the shell's thickness is defined by nodal thicknesses (“Nodal thicknesses,” Section 2.1.3), the rebar position in the thickness direction will be scaled by the ratio of the thickness defined by the nodal thickness to the thickness defined by the section definition. If the shell's thickness is defined by an element property assignment (“Assigning element properties on an element-by-element basis,” Section 13.1.5), the rebar position in the thickness direction will be scaled by the ratio of the thickness defined by the element property assignment to the thickness defined by the section definition. A positive angle

, in degrees, between the default local 1-direction and the rebars. See “Conventions,” Section 1.2.2, for a definition of the default projected local directions on a surface in space. If the shell's thickness is defined by nodal thicknesses (“Nodal thicknesses,” Section 2.1.3), the rebar position in the thickness direction will be scaled by the ratio of the thickness defined by the nodal thickness to the thickness defined by the section definition. If the shell's thickness is defined by an element property assignment (“Assigning element properties on an element-by-element basis,” Section 13.1.5), the rebar position in the thickness direction will be scaled by the ratio of the thickness defined by the element property assignment to the thickness defined by the section definition. A positive angle ![]() defines a rotation from local direction 1 to local direction 2 around the element's normal direction. For example, in a membrane the following data would result in the rebar definition shown in Figure 2.2.4–4:

defines a rotation from local direction 1 to local direction 2 around the element's normal direction. For example, in a membrane the following data would result in the rebar definition shown in Figure 2.2.4–4: ![]() =0.05,

=0.05, ![]() =0.1, and

=0.1, and ![]() =45.

=45.

When a user-defined local orientation definition is not used to define the angular orientation of the rebar and the normal to the shell is nearly parallel to the global 1-axis, the local 1-axis may change significantly within an element or from one element to the next (see “Conventions,” Section 1.2.2).

| Input File Usage: | Use the following option to define skew rebars relative to the default projected local coordinate system in three-dimensional shell elements: |

*REBAR, ELEMENT=SHELL, MATERIAL=mat, GEOMETRY=SKEW Use the following option to define skew rebars relative to the default projected local coordinate system in general membrane elements: *REBAR, ELEMENT=MEMBRANE, MATERIAL=mat, GEOMETRY=SKEW |

To define skew rebars relative to a user-defined local coordinate system, you specify the elements that contain the rebars; the cross-sectional area, ![]() , of each rebar; the rebar spacing in the plane,

, of each rebar; the rebar spacing in the plane, ![]() ; the position of the rebars in the thickness direction (for shell elements only), measured from the midsurface of the shell (positive in the direction of the positive normal to the shell); and the angle,

; the position of the rebars in the thickness direction (for shell elements only), measured from the midsurface of the shell (positive in the direction of the positive normal to the shell); and the angle, ![]() , in degrees, between the user-defined 1-direction and the rebars. See “Orientations,” Section 2.2.5, for a description of how the local coordinate system is calculated from the user-defined directions for definition of rebar in shells and membranes. A positive angle

, in degrees, between the user-defined 1-direction and the rebars. See “Orientations,” Section 2.2.5, for a description of how the local coordinate system is calculated from the user-defined directions for definition of rebar in shells and membranes. A positive angle ![]() defines a rotation from local direction 1 to local direction 2 around the user-defined normal direction. For example, in a shell the following data would result in the skew rebar definition shown in Figure 2.2.4–5:

defines a rotation from local direction 1 to local direction 2 around the user-defined normal direction. For example, in a shell the following data would result in the skew rebar definition shown in Figure 2.2.4–5: ![]() =0.01;

=0.01; ![]() =0.1; distance of rebar from the shell midsurface=0.0;

=0.1; distance of rebar from the shell midsurface=0.0; ![]() =30.; and the rebar definition refers to a local rectangular orientation defined to have its

=30.; and the rebar definition refers to a local rectangular orientation defined to have its ![]() -axis go through the point (–0.7071, 0.7071, 0.0), its

-axis go through the point (–0.7071, 0.7071, 0.0), its ![]() –

–![]() plane include the point (–0.7071, –0.7071, 0.0), and an additional rotation of 0.0 degrees about the 3-direction.

plane include the point (–0.7071, –0.7071, 0.0), and an additional rotation of 0.0 degrees about the 3-direction.

| Input File Usage: | Use the following option to define skew rebars relative to a user-defined local coordinate system in three-dimensional shell elements: |

*REBAR, ELEMENT=SHELL, MATERIAL=mat, GEOMETRY=SKEW, ORIENTATION=name Use the following option to define skew rebars relative to a user-defined local coordinate system in general membrane elements: *REBAR, ELEMENT=MEMBRANE, MATERIAL=mat, GEOMETRY=SKEW, ORIENTATION=name |

Rebars in an axisymmetric membrane must lie in the membrane reference surface, whereas rebars in an axisymmetric shell can lie in the shell reference surface or can be offset from the midsurface. Rebars in axisymmetric shells and membranes can be defined to have any orientation with respect to the ![]() –

–![]() plane. See Figure 2.2.4–6 for an example of circumferential rebars and Figure 2.2.4–7 for an example of radial rebars in axisymmetric shells.

plane. See Figure 2.2.4–6 for an example of circumferential rebars and Figure 2.2.4–7 for an example of radial rebars in axisymmetric shells.

You specify the cross-sectional area, ![]() , of each rebar; the rebar spacing,

, of each rebar; the rebar spacing, ![]() ; for shell elements the position of the rebars in the shell thickness direction, measured from the midsurface of the shell (positive in the direction of the positive normal to the shell); the angular orientation with respect to the

; for shell elements the position of the rebars in the shell thickness direction, measured from the midsurface of the shell (positive in the direction of the positive normal to the shell); the angular orientation with respect to the ![]() –

–![]() plane,

plane, ![]() , measured in degrees; and the radial position at which the rebar spacing is measured. The angular orientation is measured positive about the positive normal to the shell or membrane element. If the shell's thickness is defined by nodal thicknesses (“Nodal thicknesses,” Section 2.1.3), the distance from the midsurface will be scaled by the ratio of the thickness defined by the nodal thickness to the thickness defined by the section definition. If the shell's thickness is defined by an element property assignment (“Assigning element properties on an element-by-element basis,” Section 13.1.5), the distance from the midsurface will be scaled by the ratio of the thickness defined by the element property assignment to the thickness defined by the section definition.

, measured in degrees; and the radial position at which the rebar spacing is measured. The angular orientation is measured positive about the positive normal to the shell or membrane element. If the shell's thickness is defined by nodal thicknesses (“Nodal thicknesses,” Section 2.1.3), the distance from the midsurface will be scaled by the ratio of the thickness defined by the nodal thickness to the thickness defined by the section definition. If the shell's thickness is defined by an element property assignment (“Assigning element properties on an element-by-element basis,” Section 13.1.5), the distance from the midsurface will be scaled by the ratio of the thickness defined by the element property assignment to the thickness defined by the section definition.

If an orientation angle other than 0 or 90° is specified for rebar in an axisymmetric shell or membrane without twist, ABAQUS assumes that the rebars are balanced (i.e., half the rebar lie at the specified angle ![]() and the other half at an angle of

and the other half at an angle of ![]() ) and internal calculations are handled accordingly. See “Rebar modeling in two dimensions,” Section 3.7.1 of the ABAQUS Theory Manual, for details. If the symmetric model generation capability (“Symmetric model generation,” Section 7.8.1) is used to create a three-dimensional model from an axisymmetric shell or membrane model, only balanced rebars will be translated appropriately. The definition of balanced rebars in the axisymmetric model will result in balanced rebars in the three-dimensional model; such a translation with unbalanced rebars is not available. Unbalanced rebars in generalized axisymmetric membranes with twist will be translated properly.

) and internal calculations are handled accordingly. See “Rebar modeling in two dimensions,” Section 3.7.1 of the ABAQUS Theory Manual, for details. If the symmetric model generation capability (“Symmetric model generation,” Section 7.8.1) is used to create a three-dimensional model from an axisymmetric shell or membrane model, only balanced rebars will be translated appropriately. The definition of balanced rebars in the axisymmetric model will result in balanced rebars in the three-dimensional model; such a translation with unbalanced rebars is not available. Unbalanced rebars in generalized axisymmetric membranes with twist will be translated properly.

If the radial position for the rebar spacing is given, the total cross-sectional area of rebar will remain constant as the radial position changes; this behavior corresponds to the number of rebar in the circumferential direction remaining constant and implies that the thickness of the smeared layer of rebar decreases and that the spacing of the rebars increases as ![]() increases (see Figure 2.2.4–7). If the radial position for the rebar spacing is omitted (or is set to zero), ABAQUS assumes that the spacing of the rebar remains constant; the thickness of the corresponding smeared layer is held fixed such that

increases (see Figure 2.2.4–7). If the radial position for the rebar spacing is omitted (or is set to zero), ABAQUS assumes that the spacing of the rebar remains constant; the thickness of the corresponding smeared layer is held fixed such that ![]() .

.

| Input File Usage: | Use the following option to define rebars in an axisymmetric shell element: |

*REBAR, ELEMENT=AXISHELL, MATERIAL=mat Use the following option to define rebars in an axisymmetric membrane element: *REBAR, ELEMENT=AXIMEMBRANE, MATERIAL=mat |

Two- or three-dimensional continuum (solid) elements can contain rebars; rebars cannot be defined in triangular, prism, tetrahedral, or infinite elements. If triangular or wedge-shaped elements are needed, collapsed quadrilateral or brick elements can be used. Be careful when collapsing elements that contain rebar. It is important to check that the location and orientation of the rebar are correct.

Rebars are defined as single bars or in layers. In the latter case the layer is a surface in each element; you provide the rebar orientation in the surface.

By default, the rebars form a layer that lies in a surface that is at right angles to the plane of the model. You define the line where this rebar surface intersects the plane of the model, as described below.

The orientation of the rebars within the rebar surface is defined by giving an angle, in degrees, between the line of intersection in the plane of the model and the rebars. This angle is measured in physical three-dimensional space, not in isoparametric space. See “Rebar modeling in two dimensions,” Section 3.7.1 of the ABAQUS Theory Manual, for details. The positive direction along the line of intersection is from the lower to the higher numbered element edge that is intersected, and a positive angle indicates rebars oriented down into the plane of the model (where the plane is parallel to the ![]() -axis in plane strain analysis or the

-axis in plane strain analysis or the ![]() -axis for axisymmetric analysis), as shown in Figure 2.2.4–8.

-axis for axisymmetric analysis), as shown in Figure 2.2.4–8.

If an orientation angle other than 0 or 90° is specified for rebar in an axisymmetric element without twist, it is assumed that the rebar in the element are balanced (i.e., half the rebar lie at the specified angle ![]() and the other half at the angle

and the other half at the angle ![]() ).

).

For isoparametric rebars the intersection of the rebar layer with the plane of the model will lie along the mapping of a constant isoparametric line in the element. You specify the elements that contain the rebars; the cross-sectional area, ![]() , of each rebar; the rebar spacing,

, of each rebar; the rebar spacing, ![]() ; the rebar orientation,

; the rebar orientation, ![]() (as described above); the fractional distance from the edge,

(as described above); the fractional distance from the edge, ![]() (the ratio of the distance between the edge and the rebar to the distance across the element); and the edge number from which the rebars are defined. In addition, for axisymmetric elements you specify the radial position at which the rebar spacing is measured.

(the ratio of the distance between the edge and the rebar to the distance across the element); and the edge number from which the rebars are defined. In addition, for axisymmetric elements you specify the radial position at which the rebar spacing is measured.

If the radial position for the rebar spacing is given for rebar in axisymmetric elements, the total cross-sectional area of rebar will remain constant as the radial position changes; this behavior corresponds to the number of rebar remaining constant as ![]() increases; that is, the thickness of the smeared layer of rebar decreases as

increases; that is, the thickness of the smeared layer of rebar decreases as ![]() increases. If the radial position for the rebar spacing is omitted (or is set to zero), ABAQUS assumes that the spacing of the rebar remains constant; the thickness of the corresponding smeared layer is held fixed such that

increases. If the radial position for the rebar spacing is omitted (or is set to zero), ABAQUS assumes that the spacing of the rebar remains constant; the thickness of the corresponding smeared layer is held fixed such that ![]() .

.

Figure 2.2.4–9 shows an example of isoparametric rebar.

In the isoparametric mapping of the element, the line of rebars is parallel to one of the edges of the element. In this figure the line for rebar layer| Input File Usage: | Use the following option to define layers of isoparametric rebars in planar and axisymmetric continuum elements: |

*REBAR, ELEMENT=CONTINUUM, MATERIAL=mat, GEOMETRY=ISOPARAMETRIC |

For skew rebars the intersection of the rebar layer with the plane of the model can intersect any two edges of an element. You specify the elements that contain the rebars; the cross-sectional area, ![]() , of each rebar; the rebar spacing,

, of each rebar; the rebar spacing, ![]() ; and the rebar orientation,

; and the rebar orientation, ![]() (as described above). In addition, for axisymmetric elements you specify the radial position at which the rebar spacing is measured. You also specify the fractional distance along the element edge, from the first node of the edge (as listed in Figure 2.2.4–10) to where the rebar layer intersects the edge, for all edges. Only the two values corresponding to the two edges that the rebar intersects can be nonzero.

(as described above). In addition, for axisymmetric elements you specify the radial position at which the rebar spacing is measured. You also specify the fractional distance along the element edge, from the first node of the edge (as listed in Figure 2.2.4–10) to where the rebar layer intersects the edge, for all edges. Only the two values corresponding to the two edges that the rebar intersects can be nonzero.

Figure 2.2.4–10 shows an example of skew rebar. In the isoparametric mapping of the element, the line of rebars intersects two of the element edges. The intersection points are located by defining a fractional distance along each intersected edge. In this figure rebar layer ![]() is defined by the ratio

is defined by the ratio ![]() along edge 1 and the ratio

along edge 1 and the ratio ![]() along edge 2. Rebar layer

along edge 2. Rebar layer ![]() is defined by the ratio

is defined by the ratio ![]() along edge 3 and the ratio

along edge 3 and the ratio ![]() along edge 4.

along edge 4.

Defining skew rebars in continuum elements can increase the run time for an ABAQUS/Explicit analysis significantly. The element's stable time increment will, in most cases, be determined by the stable time increment of the rebar, which is proportional to the rebar length. If a skew rebar in a continuum element is defined such that it intersects two adjacent element edges, the resulting rebar length could be considerably less than the average element edge length, thus resulting in a very small element stable time increment.

| Input File Usage: | Use the following option to define layers of skew rebars in planar and axisymmetric continuum elements: |

*REBAR, ELEMENT=CONTINUUM, MATERIAL=mat, GEOMETRY=SKEW |

You can define single rebars in axisymmetric and generalized plane strain continuum elements. In this case the rebar is assumed to be at right angles with the plane of the model—in the thickness direction for generalized plane strain elements or the hoop direction for axisymmetric elements.

The intersection of the rebar with the plane of the model is defined by the fractional distances along edges 1 and 2 of the intersections of constant isoparametric lines that pass through the rebar location (see Figure 2.2.4–11). The fractional distances are measured from the first edge node listed in Figure 2.2.4–11.

You specify the elements that contain the rebars; the cross-sectional area, ![]() , of each rebar; and the fractional distances locating the rebar's position in the element,

, of each rebar; and the fractional distances locating the rebar's position in the element, ![]() and

and ![]() .

.

| Input File Usage: | Use the following option to define single rebars in axisymmetric and generalized plane strain continuum elements: |

*REBAR, ELEMENT=CONTINUUM, MATERIAL=mat, SINGLE |

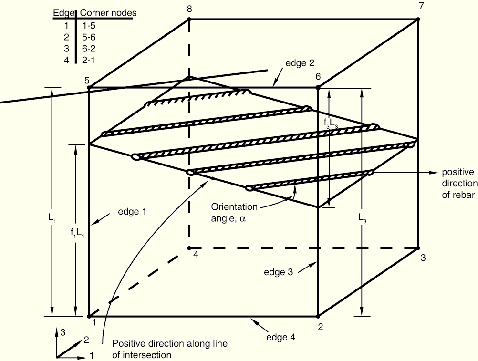

By default, the rebars in three-dimensional continuum elements are defined as layers lying in surfaces. The surfaces are most easily defined with respect to the isoparametric mapped cube of the element. Therefore, you must consider how the rebar will be defined before generating the mesh; if the rebar surfaces are not taken into account in designing the mesh, the rebar definition can be very inefficient.

In the isoparametric mapped cube the rebar surface always has two edges (opposite to one another) that are parallel to an isoparametric direction. The isoparametric directions are defined in Figure 2.2.4–12. You specify this isoparametric direction (1, 2, or 3).

A particular face of the element, which is perpendicular to this isoparametric direction in the isoparametric mapped cube, is used to define the position of the other two edges of the surface; the faces are defined in Figure 2.2.4–12, where the edges of the faces are also defined.

If isoparametric rebars are defined, the two edges of the rebar surface that are not parallel to the user-specified isoparametric direction will be parallel to one of the other two isoparametric directions; in the isoparametric-mapped cube one isoparametric coordinate is constant on the rebar surface. Figure 2.2.4–13 illustrates this concept with an element containing two layers of isoparametric rebars.

The position of each surface is given by the fractional distanceIf skew rebars are defined, the two edges of the rebar surface, which are not parallel to the user-specified isoparametric direction, are generally not parallel to one of the other isoparametric directions. The positions of these two edges of the rebar surface are specified by the intersection of the rebar surface with edges of the intersecting face, defined in Figure 2.2.4–12, for the isoparametric direction chosen; the intersections are given by the fractional distance ![]() along each edge of the face. (Note that the fractional distance is along the edge for skew rebars; for isoparametric rebars the fractional distances are measured from an edge.) The fractional distance along an edge is measured from the first node of the edge. All four fractional distances must be given, but only two can be nonzero.

along each edge of the face. (Note that the fractional distance is along the edge for skew rebars; for isoparametric rebars the fractional distances are measured from an edge.) The fractional distance along an edge is measured from the first node of the edge. All four fractional distances must be given, but only two can be nonzero.

The orientation angle, ![]() , of the rebars within the rebar layer is defined in the isoparametric-mapped cube; it is measured in degrees and is the angle between the line of intersection of the rebar surface with the face for the isoparametric direction chosen and the rebar. The positive direction of the line of intersection is from the lower numbered edge to the higher numbered edge; the positive direction for the rebars points into the elements. An example is shown in Figure 2.2.4–14.

, of the rebars within the rebar layer is defined in the isoparametric-mapped cube; it is measured in degrees and is the angle between the line of intersection of the rebar surface with the face for the isoparametric direction chosen and the rebar. The positive direction of the line of intersection is from the lower numbered edge to the higher numbered edge; the positive direction for the rebars points into the elements. An example is shown in Figure 2.2.4–14.

Figure 2.2.4–14 Orientation example for three-dimensional skew rebar modeling, isoparametric direction 2. Shown in the mapped isoparametric element.

If the rebar layer is not flat in physical space, the orientation angle at each integration point may be different. Since it is possible to define only one orientation angle per element, an average value orientation angle for the element must be used; for reasonable meshes this approximation should not affect the results significantly.

You specify the elements that contain the rebars; the cross-sectional area, ![]() , of each rebar; the rebar spacing,

, of each rebar; the rebar spacing, ![]() ; the rebar orientation,

; the rebar orientation, ![]() (as described above); the fractional distance,

(as described above); the fractional distance, ![]() , from the edge; the number of the edge from which the fractional distance is measured; and the isoparametric direction of the rebar surface.

, from the edge; the number of the edge from which the fractional distance is measured; and the isoparametric direction of the rebar surface.

| Input File Usage: | Use the following option to define layers of isoparametric rebars in three-dimensional continuum elements: |

*REBAR, ELEMENT=CONTINUUM, MATERIAL=mat, GEOMETRY=ISOPARAMETRIC |

For example, the following input defines the isoparametric rebar shown in Figure 2.2.4–13:

*HEADING ISOPARAMETRIC REBAR *NODE 1, 0., 0. 2, 10., 0. 3, 10., 5. 4, 0., 5. 5, 0., 0., 7.5 6, 10., 0., 12.5 7, 10., 5., 12.5 8, 0., 5., 7.5 *ELEMENT, TYPE=C3D8R, ELSET=ONE 1,1,2,3,4,5,6,7,8 *REBAR, ELEMENT=CONTINUUM, MATERIAL=STEEL, GEOMETRY=ISOPARAMETRIC, NAME=LAYER_A ONE,.04,2.5,49.32628,0.25,4,2 *REBAR, ELEMENT=CONTINUUM, MATERIAL=STEEL, GEOMETRY=ISOPARAMETRIC, NAME=LAYER_B ONE,.04,1.,63.43494,0.5,3,2 *MATERIAL, NAME=STEEL *ELASTIC 30.E6, …

The fractional distance defining the position of intersection of layer ![]() with this face can be measured from edge 4 (edge with nodes 2–1) along edge 3 (edge with nodes 6–2), as shown in Figure 2.2.4–13. For layer

with this face can be measured from edge 4 (edge with nodes 2–1) along edge 3 (edge with nodes 6–2), as shown in Figure 2.2.4–13. For layer ![]() ,

, ![]() . It could also be given from edge 2 (edge with nodes 5–6), so that

. It could also be given from edge 2 (edge with nodes 5–6), so that ![]() .

.

The orientation of rebar for layer ![]() in physical space is defined by an angle,

in physical space is defined by an angle, ![]() , equal to 30° for layer

, equal to 30° for layer ![]() . This angle must be transformed into the corresponding angle in the isoparametric-mapped cube. This transformation can be done as follows: consider a single rebar that intersects the intersecting line (described above) and an adjacent edge (see Figure 2.2.4–15).

. This angle must be transformed into the corresponding angle in the isoparametric-mapped cube. This transformation can be done as follows: consider a single rebar that intersects the intersecting line (described above) and an adjacent edge (see Figure 2.2.4–15).

![]()

The fractional distance defining the position of the intersection of layer ![]() with this face can be measured from edge 3 (edge with nodes 6–2);

with this face can be measured from edge 3 (edge with nodes 6–2); ![]() . It could also be measured from edge 1 (edge with nodes 1–5), such that

. It could also be measured from edge 1 (edge with nodes 1–5), such that ![]() . The orientation angle for layer

. The orientation angle for layer ![]() in the rebar layer is 45°. In the isoparametric-mapped cube

in the rebar layer is 45°. In the isoparametric-mapped cube ![]() ,

, ![]() ,

, ![]() , and

, and ![]() .

.

Since an isoparametric rebar layer always lies in two of the isoparametric directions, an alternative but equivalent definition can be given. For example, layer ![]() also lies in isoparametric direction 1, with the intersecting face having nodes 1-4-8-5. The fractional distance for layer

also lies in isoparametric direction 1, with the intersecting face having nodes 1-4-8-5. The fractional distance for layer ![]() , measured from edge 1 (edge with nodes 1–4), is

, measured from edge 1 (edge with nodes 1–4), is ![]() . The positive sense of the line of intersection is from edge 2 (edge with nodes 4–8) to edge 4 (edge with nodes 5–1); therefore,

. The positive sense of the line of intersection is from edge 2 (edge with nodes 4–8) to edge 4 (edge with nodes 5–1); therefore, ![]() ,

, ![]() ,

, ![]() , and

, and ![]() .

.

Layer ![]() also lies in isoparametric direction 3, with the intersecting face having nodes 1-2-3-4. The fractional distance for layer

also lies in isoparametric direction 3, with the intersecting face having nodes 1-2-3-4. The fractional distance for layer ![]() , measured from edge 2 (edge with nodes 2–3), is

, measured from edge 2 (edge with nodes 2–3), is ![]() . The positive sense of the intersecting line is from edge 1 (edge with nodes 1–2) to edge 3 (edge with nodes 3–4); therefore, the orientation angle of the rebar in physical space is

. The positive sense of the intersecting line is from edge 1 (edge with nodes 1–2) to edge 3 (edge with nodes 3–4); therefore, the orientation angle of the rebar in physical space is ![]() ,

, ![]() ,

, ![]() , and in the isoparametric-mapped cube

, and in the isoparametric-mapped cube ![]() .

.

You specify the elements that contain the rebars; the cross-sectional area, ![]() , of each rebar; the rebar spacing,

, of each rebar; the rebar spacing, ![]() ; the rebar orientation,

; the rebar orientation, ![]() (as described above); and the isoparametric direction. In addition, you specify the fractional distance

(as described above); and the isoparametric direction. In addition, you specify the fractional distance ![]() along the element edge for each edge of the intersecting face defined in Figure 2.2.4–12. Only the values corresponding to the two edges that the rebar intersects can be nonzero.

along the element edge for each edge of the intersecting face defined in Figure 2.2.4–12. Only the values corresponding to the two edges that the rebar intersects can be nonzero.

| Input File Usage: | Use the following option to define layers of skew rebars in three-dimensional continuum elements: |

*REBAR, ELEMENT=CONTINUUM, MATERIAL=mat, GEOMETRY=SKEW |

For example, the following input defines the skew rebar shown in Figure 2.2.4–16:

*HEADING *NODE 1, 0., 0. 2, 10., 0. 3, 10., 5. 4, 0., 5. 5, 0., 0., 7.5 6, 10., 0., 12.5 7, 10., 5., 12.5 8, 0., 5., 7.5 *ELEMENT, TYPE=C3D8R, ELSET=ONE 1,1,2,3,4,5,6,7,8 *REBAR, ELEMENT=CONTINUUM, MATERIAL=STEEL, GEOMETRY=SKEW, NAME=LAYER_A ONE, .04, 2.5, 55.28, , 2 .2, 0., .4, .0 *MATERIAL, NAME=STEEL *ELASTIC 30.E6, …

You can define single rebars in three-dimensional continuum elements; in this case the rebar is assumed to be placed along one of the element's isoparametric directions. The rebar is then located by its intersection with the intersecting face (defined in Figure 2.2.4–12). The intersections of constant isoparametric lines with edges 1 and 2 of the intersecting face are given by fractional distances along edges 1 and 2, measured from the first node of each edge, as shown in Figure 2.2.4–11.

You specify the elements that contain the rebars; the cross-sectional area, ![]() , of each rebar; the fractional distances locating the rebar's position in the element,

, of each rebar; the fractional distances locating the rebar's position in the element, ![]() and

and ![]() ; and the isoparametric direction. Give the fractional distances with respect to edge 1 and edge 2 for the isoparametric direction chosen, as defined in Figure 2.2.4–12.

; and the isoparametric direction. Give the fractional distances with respect to edge 1 and edge 2 for the isoparametric direction chosen, as defined in Figure 2.2.4–12.

| Input File Usage: | Use the following option to define single rebars in three-dimensional continuum elements: |

*REBAR, ELEMENT=CONTINUUM, MATERIAL=mat, SINGLE |

The material properties of the rebars are distinct from those of the underlying element and are defined by a separate material definition (“Material data definition,” Section 9.1.2). You must associate each rebar definition with a set of material properties.

The following material behavior cannot be used in ABAQUS/Standard to define rebar materials:

The following material behaviors cannot be used in ABAQUS/Explicit to define rebar materials:Although ABAQUS/Standard will allow for a rebar material to be defined with orthotropic elasticity (“Defining orthotropic elasticity by specifying the terms in the elastic stiffness matrix” in “Linear elastic behavior,” Section 10.2.1) or anisotropic elasticity (“Defining fully anisotropic elasticity” in “Linear elastic behavior,” Section 10.2.1), ![]() is the only meaningful material constant in these definitions.

is the only meaningful material constant in these definitions. ![]() is used to compute the strain in the rebar direction,

is used to compute the strain in the rebar direction, ![]() , using the corresponding stress component,

, using the corresponding stress component, ![]() , as discussed in “Linear elastic behavior,” Section 10.2.1; no other strain or stress components exist in rebars.

, as discussed in “Linear elastic behavior,” Section 10.2.1; no other strain or stress components exist in rebars.

In ABAQUS/Standard density is ignored for the rebar material properties. Hence, the mass of the rebar is neglected in eigenvalue extraction and implicit dynamic procedures and for gravity, centrifugal, and rotary acceleration distributed loads.

| Input File Usage: | Use the following option to associate a material definition with a rebar definition: |

*REBAR, ELEMENT=elem, MATERIAL=mat |

Initial conditions (“Initial conditions,” Section 19.2.1) can be used to define rebar prestress or solution-dependent values for rebars.

For structures in which reinforcing is defined (such as reinforced concrete structures), you can use initial conditions to define the prestress in the rebars.

In such cases in ABAQUS/Standard the structure must be brought to a state of equilibrium before it is actively loaded by means of an initial static analysis step (“Static stress analysis,” Section 6.2.2) with no external loads applied (or, perhaps, with the “dead” loads only)—see “Defining initial stresses” in “Initial conditions,” Section 19.2.1.

| Input File Usage: | *INITIAL CONDITIONS, TYPE=STRESS, REBAR element number or element set name, rebar name, prestress value |

If prestress is defined in the rebars and unless the prestress is held fixed, it will be allowed to change during an equilibrating static analysis step; this is a result of the straining of the structure as the self-equilibrating stress state establishes itself. An example is the pretension type of concrete prestressing in which reinforcing tendons are initially stretched to a desired tension before being covered by concrete. After the concrete cures and bonds to the rebar, release of the initial rebar tension transfers load to the concrete, introducing compressive stresses in the concrete. The resulting deformation in the concrete reduces the stress in the rebar.

Alternatively, you can keep the initial stress defined in some or all of the rebars constant during this initial equilibrium solution. An example is the post-tension type of concrete prestressing; the rebars are allowed to slide through the concrete (normally they are in conduits), and the prestress loading is maintained by some external source (prestressing jacks). The magnitude of the prestress in the rebar is normally part of the design requirements and must not be reduced as the concrete compresses under the loading of the prestressing. Normally, the prestress is held constant only in the first step of an analysis. This is generally the more common assumption for prestressing.

If the prestress is not held constant in analysis steps following the step in which it is held constant, the stress in the rebar will change due to additional deformation in the concrete. If there is no additional deformation, the stress in the rebar will remain at the level set by the initial conditions. If the loading history is such that no plastic deformation is induced in the concrete or rebar in steps subsequent to the steps in which the prestress is held constant, the stress in the rebar will return to the level set by the initial conditions upon removal of the loading applied in those steps.

| Input File Usage: | *PRESTRESS HOLD |

You can define the initial values of solution-dependent state variables for rebars within elements. See “Initial conditions,” Section 19.2.1, for details.

| Input File Usage: | *INITIAL CONDITIONS, TYPE=SOLUTION, REBAR |

Rebar force output is available at the rebar integration locations with output variable RBFOR. The rebar force is equal to the rebar stress times the current rebar cross-sectional area. The current cross-sectional area of the rebar is calculated by assuming the rebar is made of an incompressible material, regardless of the actual material definition. For rebars in membrane or shell elements output variables RBANG and RBROT identify the current orientation of isoparametric or skew rebar within the element and the relative rotation of the rebar as a result of finite deformation, respectively. These quantities are measured with respect to the user-specified isoparametric direction in the element, not the default local element system or the orientation-defined system. See “Rebar modeling in shell, membrane, and surface elements,” Section 3.7.3 of the ABAQUS Theory Manual.

See “ABAQUS/Standard output variable identifiers,” Section 4.2.1, and “ABAQUS/Explicit output variable identifiers,” Section 4.2.2, for information on additional output quantities such as stress and strain. For rebars in membrane or shell elements with multiple integration points, output quantities are available at the integration points and at the centroid of the element.

The output quantities RBANG and RBROT can be measured from either of the isoparametric directions in the plane of the shell or the membrane. You can specify the desired isoparametric direction from which the rebar angle will be measured (1 or 2). In axisymmetric shells and membranes the first isoparametric direction coincides with the meridional direction, and the second isoparametric direction coincides with the hoop direction. The rebar angle is measured from the isoparametric direction to the rebar with a positive angle defined as a counterclockwise rotation around the element's normal direction. The default direction is the first isoparametric direction.

| Input File Usage: | Use any of the following options: |

*REBAR, ELEMENT=SHELL, MATERIAL=mat, ISODIRECTION=n *REBAR, ELEMENT=AXISHELL, MATERIAL=mat, ISODIRECTION=n *REBAR, ELEMENT=MEMBRANE, MATERIAL=mat, ISODIRECTION=n *REBAR, ELEMENT=AXIMEMBRANE, MATERIAL=mat, ISODIRECTION=n |

As an example, a user-defined local coordinate system is used to define skewed rebar in a shell element (skew angle ![]() ), and the output value of RBANG is 75°, as illustrated in Figure 2.2.4–17:

), and the output value of RBANG is 75°, as illustrated in Figure 2.2.4–17:

Figure 2.2.4–17 RBANG measurement for skew rebar defined relative to user-defined local coordinate directions.

*REBAR, ELEMENT=SHELL, MATERIAL=MAT1, NAME=REBARB, GEOMETRY=SKEW, ORIENTATION=ORIENT, ISODIRECTION=2 ELSET1, 0.01, 0.1, 0.0, 30. *ORIENTATION, SYSTEM=RECTANGULAR, NAME=ORIENT -0.7071, 0.7071, 0.0, -0.7071, -0.7071, 0.0 3, 0.0

ABAQUS/CAE does not support visualization of element-based rebar or rebar results. ABAQUS/CAE does support visualization of rebar defined as described in “Defining reinforcement,” Section 2.2.3.