The Powers of Induction

Contents

Blake Bordelon and Elizabeth Onder

Overview

The goal of our project is to create a wireless charging pad capable of transferring power from a base station powered by a Lithium Ion battery to a receiver system that outputs power to a standard port at 5 V and .5 A. The device will consist of a transmitter base and a receiver, each of which will house an inductive coil capable of coupling at close distances. Unlike many wireless chargers on the market, our transmitter base will be powered by a 7.4 V lithium ion battery, rendering our transmitter pad portable. Switching and power delivery will be handled by an Arduino in the transmitter pad. The Arduino will switch a MOSFET transistor at a frequency between 10-20 kHz to allow for the delivery of alternating current to the primary coil. A battery management integrated circuit will be implemented in the transmitter base to prevent excessive spikes in current or voltage across our lithium ion battery. In addition, a LM60 temperature sensing IC will feed into the Arduino to allow for fail safe mechanism should the circuit get too hot. The alternating current in the primary coil should in turn produce a varying magnetic flux through the receiver coil, driving an oscillating current through the receiver. Both coils will be in parallel with capacitors in order to reduce some losses to parasitic impedance. Additional capacitors may be placed to filter the signals and to snub the inductive kickback on the transistor. The current passing through the receiver will then pass through a full bridge rectifier constructed from a diode bridge in parallel with a capacitor. This unregulated DC voltage (hovering around 7-10 V) will then pass through a 7805 Voltage Regulator to produce the desired 5 V output.

Things to mention: Arduino Transistor (switching at around 10-15 Hz) Snubbing Capacitor Temp Sensor Battery (and battery manager IC) Capacitor in parallel with the inductor. Rectifier on the side of the receiver. 7805 requires 7-18 V input and will output.

Unlike many other wireless chargers on the market, our transmitter will contain its own Lithium Ion battery in a "charge-float" circuit (charging at 4.0 V to avoid trickle charging). Safely charging the battery in the transmitter base will be handled by a battery manager IC. Thus the transmitter can provide power to the receiver while plugged into a standard 5 V USB port or while isolated from an outlet. Our charging station, therefore, will be portable unlike many similar devices on the market. The transmitter part of the device will contain an Arduino capable of smartly manipulating power delivery by switching a transistor to at a frequency near 12kHz. A current sensing circuit on the transmitter side will trip when a load receiver coil is introduced so that the transmitter does not waste power when there is no receiver present. The switching, which will allow for small changes in frequency to account for small perturbations in distance or orientation of the receiver, will be handled by an algorithm running on the Arduino. To avoid overheating, our charging base will contain a temperature sensing circuit, which will interface with the Arduino so that the device can shut off if the temperature gets too high. As power is transferred to the receiver coil, a rectifier will turn the AC into the 4.2 V DC required to charge the battery on the receiver side.

Objectives

- The objective of this project is to create a working wireless battery charger as described above. The station should be able to operate in a loosely coupled resonant state with the receiver when the phone is above the stand and in use and in a tightly coupled inductive state when the phone is placed on the pad. When operating at near resonance, power can be transferred from the charging stand to a phone held above the pad with minimized losses to complex impedance. However, at short distances, tight inductive coupling is preferred due to lower electromagnetic and heat emissions. The inclusion of microcontrollers in a feedback loop will help improve power delivery. For the demo, we intend to have people with compatible phone models place their phones on the charger. For those with iPhones, will also 3D print a phone case that will house an iPhone wireless adapter. The goal will be for the phones to give an indication that they are in fact charging.

Challenges

In order to accomplish the above stated goals, we must learn:

- How to use PSpice/MutliSim or some other circuit simulation software to create a schematic of our design and simulate its behavior under different parameters.

- How to use SolidWorks or equivalent 3D design software to design our iPad case and the body of the charging stand.

- How to configure the internal battery within the charging stand so that it can both be charged by an exterior wall outlet and can provide power to the transmitting coil.

- How to program on Arduino

- How to design and implement control algorithms to improve power delivery for multiple phone orientations.

- How to wind coils of wire to obtain desired specifications.

- About basic manufacturing standards for wireless compatible phones and other components that will be included in our design.

In addition, we will encounter the following safety challenge:

- To ensure user safety, we will need to figure out how to detect temperature of the charging stand with our microcontrollers so that the device can power off it it gets too hot (loose resonant coupling can have higher heat emissions than tight coupling).

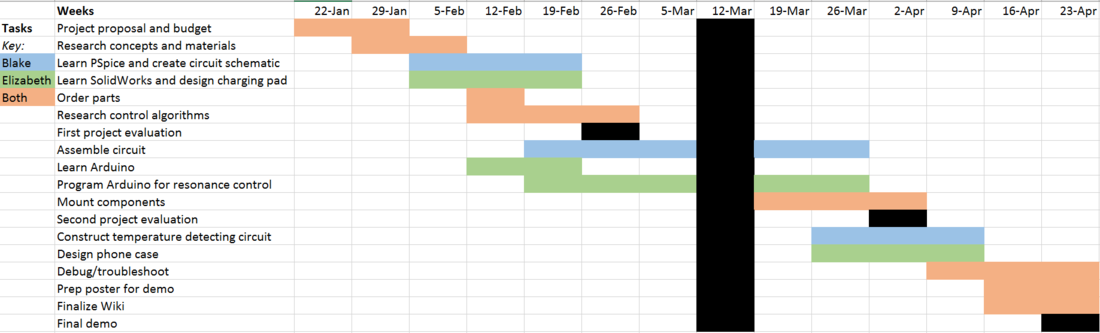

Gantt Chart

Budget

- Two wireless charging coils:2 x $8.22 = $16.44 (Link)

- Battery Management IC: $4.50 (Link)

- Lithium Ion Battery Charger: $14.99 (Link)

- 7805 Voltage Regulator: $0.95 (Link)

- Temperature Sensor: $0.69 (Link)

- Two 7.4 V, Lithium Ion Batteries: One supplied by class, one is $19.99 (Link)

- Arduino: supplied by class

- 3D-printed parts: supplied by class

- MultiSim Circuit simulation software: supplied by school

- MOSFET Transistor: $6.05 (Link)

- Resistors: $0.10+$0.10+$0.1+$0.56+$1.55= $2.41 (Link 1) (Link 2) (Link 3) (Link 4) (Link 5)

- Capacitors: $0.58 (Link)

- Voltage regulator: $1.68 (Link)

- Green LED: $0.35 (Link)

Total before tax and shipping: $51.51; Estimated tax: $2.17; Estimated shipping: $15; Estimated total: $68.68