Difference between revisions of "BetaDelta"

| Line 119: | Line 119: | ||

===3D Printing=== | ===3D Printing=== | ||

First, we created a model of our design in CAD. Next, we printed a scaled-down version to see if the printer could handle its shape and intricacies. Then we printed our first to-scale version, and soon after printed our final version. | First, we created a model of our design in CAD. Next, we printed a scaled-down version to see if the printer could handle its shape and intricacies. Then we printed our first to-scale version, and soon after printed our final version. | ||

| − | ====Evolution of 3D Models==== | + | =====Evolution of 3D Models===== |

[[File:P1.JPG|100px|caption =CAD drawing]] --> [[File:P2.JPG|100px|Down-Sized Print]] --> [[File:P3.JPG|100px|First To-Scale Print]] --> [[File:P4.JPG|100px|Final To-Scale Print]] | [[File:P1.JPG|100px|caption =CAD drawing]] --> [[File:P2.JPG|100px|Down-Sized Print]] --> [[File:P3.JPG|100px|First To-Scale Print]] --> [[File:P4.JPG|100px|Final To-Scale Print]] | ||

Revision as of 02:03, 2 May 2017

Contents

Overview

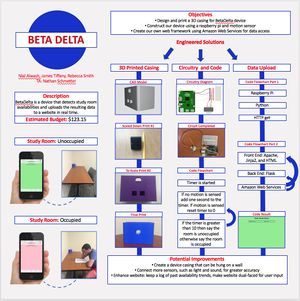

The purpose of BetaDelta is to provide real-time updates on the availability of a given study room. The information will be uploaded to a website, developed through Amazon Web Services, based on input from the BetaDelta device. The goal for the BetaDelta device is to detect occupancy via motion sensor, connected to a raspberry pi, and encased in a 3D printed shell.

Team Members

- James Tiffany

- Rebecca Smith

- Nial Alwash

- Nathan Schmetter (TA)

Objectives

Device

- Constructed with a raspberry pi and motion sensor

- Encased in a 3D printed shell

- Code the raspberry pi to receive input from the sensor and upload it onto our server

Website

- Developed with Amazon Web Services

- Have the to display updated room occupancy via wifi

- Change colors based on occupancy (red for occupied, green for available)

Challenges

- Learn Python coding techniques

- Learn how to use CAD and 3D print

- Recreate circuit tutorials for motions sensor to raspberry pi connection

- Create our own framework for the server and website using Amazon Web Services

Budget

Gantt Chart

Engineered Solutions

3D Printing

First, we created a model of our design in CAD. Next, we printed a scaled-down version to see if the printer could handle its shape and intricacies. Then we printed our first to-scale version, and soon after printed our final version.

Evolution of 3D Models

Circuitry and Code

We found a tutorial online for how to connect the motion sensor to the raspberry pi, completed the circuit, and then edited a version of code we found online using a counter technique to accept input from the sensor.

Evolution

Data Upload

We developed entirely our own framework, using bits and pieces from tens of tutorials. Our code was two-pronged, including a first set that interpreted the input from the motion sensor and raspberry pi, and a second set that handled the upload of data, display, and communication between our server and database.

Evolution

Results

Presentation Poster

Repository