Difference between revisions of "Cheers! Weekly Log"

Jessieshi97 (talk | contribs) |

Jessieshi97 (talk | contribs) |

||

| Line 76: | Line 76: | ||

#* Followed a simple tutorial to control an LED with toggle switches. | #* Followed a simple tutorial to control an LED with toggle switches. | ||

| − | <gallery mode=packed heights= | + | <gallery mode=packed heights=250px style="text-align:left"> |

File:Cpic11.png | | File:Cpic11.png | | ||

File:Cpic12.jpeg | | File:Cpic12.jpeg | | ||

| − | |||

</gallery> | </gallery> | ||

| Line 92: | Line 91: | ||

#Mechanical System | #Mechanical System | ||

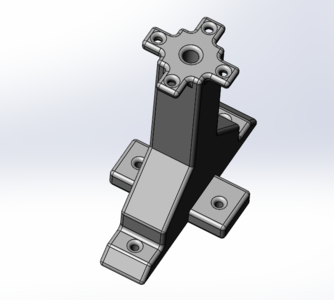

| − | #* Redesigned the bottle holder and swing so that it will be more stable and | + | #* Redesigned the bottle holder and swing so that it will be more stable and accommodate for two pair of holes for the two U bolts. |

#* Printed out the bottle holder and swing (picture shown below) | #* Printed out the bottle holder and swing (picture shown below) | ||

#* Decided to use two U bolts to keep the bottle in place better | #* Decided to use two U bolts to keep the bottle in place better | ||

| Line 101: | Line 100: | ||

#* Started Algorithm design of drawing a flowchart. | #* Started Algorithm design of drawing a flowchart. | ||

[[File:Cgif1.gif]] | [[File:Cgif1.gif]] | ||

| + | <gallery mode=packed heights=250px style="text-align:left"> | ||

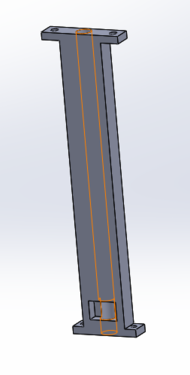

| + | File:Cpic14.png | Lower half of distance sensor suspension system | ||

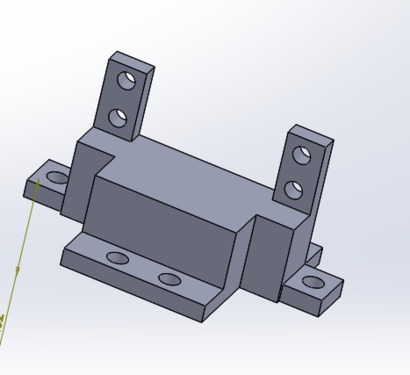

| + | File:Cpic15.png | Motor holder | ||

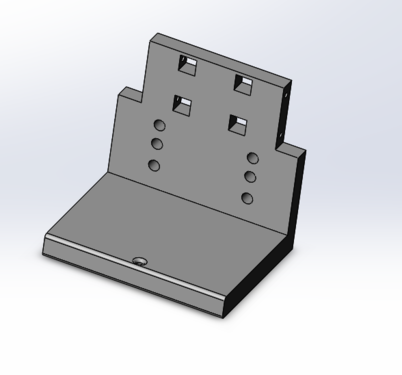

| + | File:Cpic16.png | Bottle holder base | ||

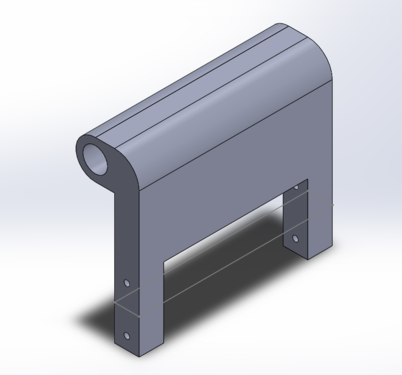

| + | File:Cpic17.png | Bottle holder swing | ||

| + | </gallery> | ||

== Week 10 (3/27-4/2) == | == Week 10 (3/27-4/2) == | ||

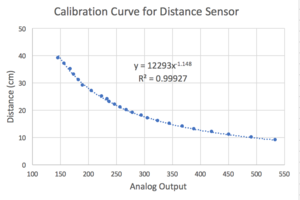

[[File:CIRCalibration.png|thumb|Calibration Curve for IR Infrared Sensor|300px]] | [[File:CIRCalibration.png|thumb|Calibration Curve for IR Infrared Sensor|300px]] | ||

Mechanical System | Mechanical System | ||

| − | |||

#* Bought wood from HomeDepot to make the wooden frame. | #* Bought wood from HomeDepot to make the wooden frame. | ||

#* Drilled holes and cut a piece off from the one of the wood to make room for pulley (took us total of 7 hours). | #* Drilled holes and cut a piece off from the one of the wood to make room for pulley (took us total of 7 hours). | ||

| Line 113: | Line 117: | ||

#* We calibrated the infrared distance sensor and generated a curve (shown on the right). We got a best fit line that translates to distance = 12293*(AnalogRead)^-1.148. | #* We calibrated the infrared distance sensor and generated a curve (shown on the right). We got a best fit line that translates to distance = 12293*(AnalogRead)^-1.148. | ||

#* Adjusted the algorithm flow chart. | #* Adjusted the algorithm flow chart. | ||

| − | + | <gallery mode=packed heights=250px style="text-align:left"> | |

| + | File:Cpic11.png | | ||

| + | File:Cpic12.jpeg | | ||

| + | File:Cpic19.png | Upper half of distance sensor suspension system | ||

| + | </gallery> | ||

== Week 11 (4/3-4/9) Second Evaluation == | == Week 11 (4/3-4/9) Second Evaluation == | ||

Revision as of 15:30, 4 April 2017

Contents

Week 1 (1/23 - 1/29)

Formulate group and brainstorm about project ideas. We decided to replicate a beer pouring machine on youtube.

Week 2 (1/30 - 2/5)

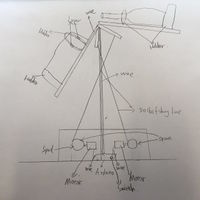

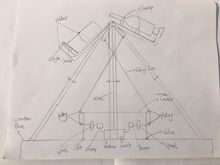

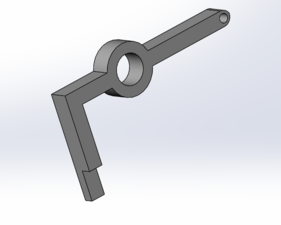

We met with Natalie (TA) to help us straighten the project objective, determine several potential challenges and write out the project proposal. We researched about the specific mechanism to control tilt angles as it was not clearly shown in the video It was decided that we use two 90 degrees lever, each for soda bottle and glassware, tied with a fishing line connected to a spool on a step motor to control the tilt angle (Figure 1). The start for the system is controlled by a push button and the stop pouring signal should be decided by laser detection. Arduino was found to be useful in the process in controlling this process. For a potentially successful project, the budget was determined after objective and challenges were identified.

Week 3 (2/6-2/12)

We compared the pros and cons of various available sensors (distance sensor, color sensor, laser sensor, liquid level sensor and weight sensors) and decided to change our laser sensor to weight sensor. Other sensors all have high chances of electric shock as it is very hard to cover the sensor to prevent liquid damage. Weight sensor could be hidden in the base holder of the glassware and the wires are sent to the Arduino board inside the support stands. In addition, we decided to put a wooden cover on the Arduino board and stepper motor. The fishing line will be sent out from the cover through a little hole and connect to the lever using four pulleys. We together altered the objective in the project proposal to make the mechanical models and its tilting mechanism more robust.

Haixiang finished the tutorial on Introduction to Solidworks and Tutorial 1. Jessie started drawing pictures for the mechanical design of the system and editing the project proposal page. We realized that 3D printing could only print a maximum length of 8 inches so we decided to print three supportive stands on each side to make a strong base, and each stand will be made out of 2 pieces of 3D printings.

Week 4 (2/13-2/19)

- Proposal

- Changed the stepper motor to servo motor to avoid from getting hot at zero speed.

- Added the 2 double pulley system to cut the weight of the bottle (with soda) to 1/4 of its original weight as sensed by the motor.

- Added the wooden cover idea to the proposal to separate the mechanical system from the electrical system. The mechanical system will be built on top of the electrical system and the wires to connect to the weight sensor is through the base (will not be out in air).

- Researched various ways of supplying power to the servo motor, whether is it through the Arduino board portal, using two separate power supplies or connecting the Arduino board and the two motor in parallel or series, etc. We decided to use a single power supply and connecting the two motors and Arduino board all parallel to each other. The power supply would be 6V 3A wall power adaptor. The two motors can operate at the voltage of 4.8V to 6V(correspond to maximum stall torque) and the Arduino board can operate at a minimum of 6V. As we will not need the Arduino board to supply a lot of power (push button and weight sensor), we thought it should be fine.

- Mechanical System

- Started building the model the part 1 of the base and learned to use the Ultimaker 2 Extended machine with Natalie and Nathan over the weekend.

- Printed the first model of base 1.

Week 5 (2/20-2/26)

- Proposal

- Went to Home Depot found a U-bolt that could serve as the bottle holder so that it can tilt more than 90 degrees.

- Ordered the pulleys.

- Mechanical System:

- Adjusted the part 1 base so that the attachment part to part 2 of the base will not interfere with the swing. The nut hole in base 1 was also adjusted.

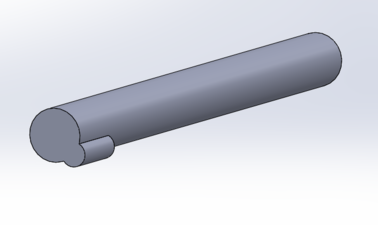

- Calculated exact parameters needed and designed part 2 of the base, the horizontal rotating axis.

- Built the 3D model for base 2 and horizontal rotation axis

- Start printing out an initial model for base 2 and horizontal axis.

- Had a rough sketch of the model for the bottle holder and the lever arm and how it will be attached to the horizontal arm.

Week 6 (2/27-3/5) First Evaluation

- Proposal

- Decided to put the electrical system on top of the mechanical system with a wooden stage, then the fishing line from the motor will be pulling from the bottom of the bottle.

- Decided to not let the glassware tilt but keep in on the table. This would make the weight sensor be more accurate in estimating the amount of soda in glassware. (as we will not be dealing with component forces of the weight of glassware with soda).

- Mechanical System

- Adjusted hole parameters on base 2 so that it could fit with base 1 and horizontal axis better.

- Redesigned the bottle holder and the swing so for the adjusted proposal.

- Printed out two base 2s and assembled the initial mechanism system without the bottle holder.

Week 7 (3/6-3/12)

- Proposal

- Ordered all parts.

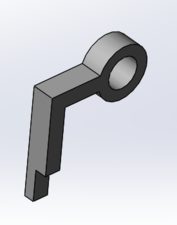

- Had a new picture representing the system (right) with target dimensions of the wooden frame.

- Added the support system for the bottle so that the motor do not have to withstand a large amount of torque while the bottle is at rest (position 1).

- Mechanical System

- Deleted the 45 degree angle to hold the bottle as it has a high chance of fracture.

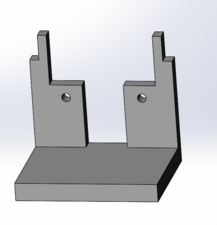

- Modified the bottle holder so that the fish lines would connect directly to the bottle holder base.

- Printed the bottle base edition 2 and assembled the mechanical design. (picture shown below)

- Electrical System

- Learned about Arduino board and breadboard.

- Followed a simple tutorial to control an LED with toggle switches.

Week 8 (3/13-3/19) Spring Break

- Mechanical System

- Designed the specific dimensions of the support system for the bottle.

- Decided to use the wood from HomeDepot instead of the provided one.

- Electrical System

- Learned how to control the motor (turning at different directions) using Arduino.

Week 9 (3/20-3/26)

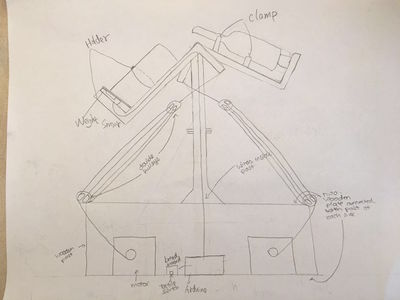

- Mechanical System

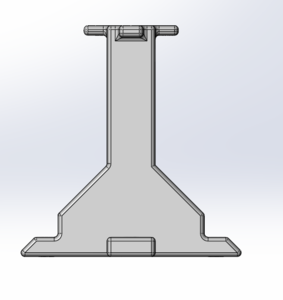

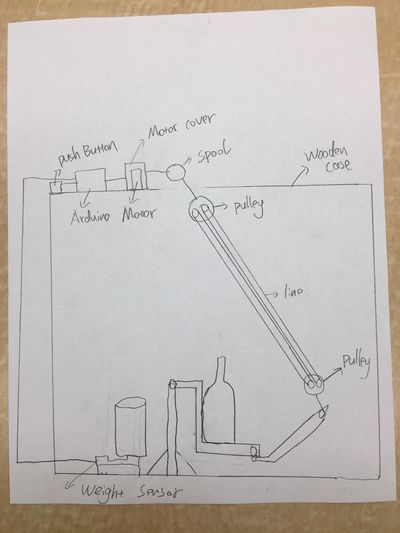

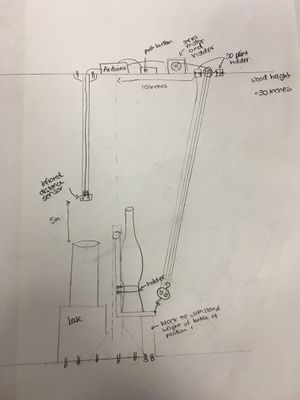

- Redesigned the bottle holder and swing so that it will be more stable and accommodate for two pair of holes for the two U bolts.

- Printed out the bottle holder and swing (picture shown below)

- Decided to use two U bolts to keep the bottle in place better

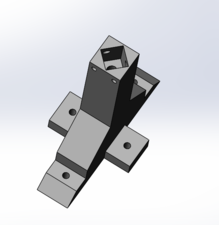

- Resigned the motor holder and printed it out.

- Designed the lower half of the IR distance sensor suspension system and printed out

- Electrical System

- Learned how to control the IR sensor using Arduino by following the link here.

- Started Algorithm design of drawing a flowchart.

Week 10 (3/27-4/2)

Mechanical System

- Bought wood from HomeDepot to make the wooden frame.

- Drilled holes and cut a piece off from the one of the wood to make room for pulley (took us total of 7 hours).

- Designed the spool to affix on the accessory on the servo motor.

- Designed the upper half of the IR distance sensor suspension system after have exact dimensions of the wooden frame.

Electrical System

- We calibrated the infrared distance sensor and generated a curve (shown on the right). We got a best fit line that translates to distance = 12293*(AnalogRead)^-1.148.

- Adjusted the algorithm flow chart.

Week 11 (4/3-4/9) Second Evaluation

Mechanical System

- Printed the spool and attached it to the servo motor.

- Designed and printed pulley stabilizer.

Electrical System

- Assembled the motor and IR distance sensor onto the wooden frame.