Difference between revisions of "The Powers of Induction"

| Line 4: | Line 4: | ||

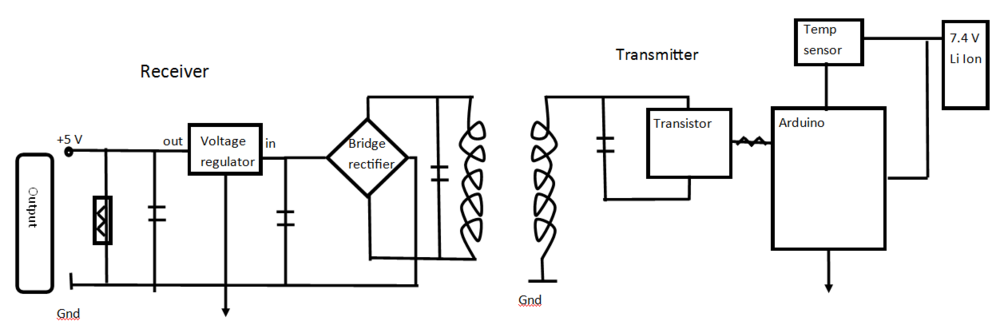

The goal of our project is to create a wireless charging pad capable of transferring power from a base station powered by a Lithium Ion battery to a receiver system that outputs power to a standard port at 5 V and .5 A. The device will consist of a transmitter base and a receiver, each of which will house an inductive coil capable of coupling at close distances. Unlike many wireless chargers on the market, our transmitter base will be powered by a 7.4 V lithium ion battery, rendering our transmitter pad portable. Switching and power delivery will be handled by an Arduino in the transmitter pad. The Arduino will switch a MOSFET transistor at a frequency between 10-20 kHz to allow for the delivery of alternating current to the primary coil. A battery management integrated circuit will be implemented in the transmitter base to prevent excessive spikes in current or voltage across our lithium ion battery. In addition, a LM60 temperature sensing IC will feed into the Arduino to allow for fail safe mechanism should the circuit get too hot. The alternating current in the primary coil should in turn produce a varying magnetic flux through the receiver coil, driving an oscillating current through the receiver. Both coils will be in parallel with capacitors in order to reduce some losses to parasitic impedance. Additional capacitors may be placed to filter the signals and to snub the inductive kickback on the transistor. The current passing through the receiver will then pass through a full bridge rectifier constructed from a diode bridge in parallel with a capacitor. This unregulated DC voltage (hovering around 7-10 V) will then pass through a 7805 Voltage Regulator to produce the desired 5 V output. Because we can control the switching frequency directly with the Arduino, we aim to experiment with our code in order to improve power delivery. | The goal of our project is to create a wireless charging pad capable of transferring power from a base station powered by a Lithium Ion battery to a receiver system that outputs power to a standard port at 5 V and .5 A. The device will consist of a transmitter base and a receiver, each of which will house an inductive coil capable of coupling at close distances. Unlike many wireless chargers on the market, our transmitter base will be powered by a 7.4 V lithium ion battery, rendering our transmitter pad portable. Switching and power delivery will be handled by an Arduino in the transmitter pad. The Arduino will switch a MOSFET transistor at a frequency between 10-20 kHz to allow for the delivery of alternating current to the primary coil. A battery management integrated circuit will be implemented in the transmitter base to prevent excessive spikes in current or voltage across our lithium ion battery. In addition, a LM60 temperature sensing IC will feed into the Arduino to allow for fail safe mechanism should the circuit get too hot. The alternating current in the primary coil should in turn produce a varying magnetic flux through the receiver coil, driving an oscillating current through the receiver. Both coils will be in parallel with capacitors in order to reduce some losses to parasitic impedance. Additional capacitors may be placed to filter the signals and to snub the inductive kickback on the transistor. The current passing through the receiver will then pass through a full bridge rectifier constructed from a diode bridge in parallel with a capacitor. This unregulated DC voltage (hovering around 7-10 V) will then pass through a 7805 Voltage Regulator to produce the desired 5 V output. Because we can control the switching frequency directly with the Arduino, we aim to experiment with our code in order to improve power delivery. | ||

| + | ==Block Diagram== | ||

[[File:Circuit1.PNG|1300px|1000px]] | [[File:Circuit1.PNG|1300px|1000px]] | ||

| Line 10: | Line 11: | ||

==Objectives== | ==Objectives== | ||

* The objective of this project is to create a working wireless power delivery system as described above. The device should be powered by the Li Ion battery and should be capable of transferring power over the coupled coils from several millimeters distance. | * The objective of this project is to create a working wireless power delivery system as described above. The device should be powered by the Li Ion battery and should be capable of transferring power over the coupled coils from several millimeters distance. | ||

| − | * For the demo, we intend to demonstrate power transfer by lighting an LED with our regulated power on the receiver end. | + | * For the demo, we intend to demonstrate power transfer by lighting an LED with our regulated power on the receiver end. Starting with the receiver module far away from the transmitter and the LED clearly off, we can move the receiver coil closer to the device. |

| + | |||

==Challenges== | ==Challenges== | ||

| − | + | * Lithium ion batteries can be dangerous if exposed to high temperatures or large fluctuations in current or voltage. Thus maintaining appropriate and safe conditions for the battery presents a significant challenge. To overcome this challenge, we aim to include a temperature fail safe from our temperature sensing IC as well as a battery management regulator IC. Should the temperature get too high, a switch should open to disconnect the battery from the circuit. | |

| − | * The | + | * Another significant challenge is the magnitude of the alternating voltage required in the receiver. The 7805 voltage regulator requires a voltage from ~7-18 V in order to produce the 5 V output. Thus the voltage across the coupled receiver coil must be around this magnitude. If we only use a 7.4 V DC battery on the transmitter side of the system, then we may not produce a high enough voltage on the receiver end to successfully produce a 5 V signal on the other side of the rectifier and 7805 voltage regulator. We may have to choose or design a receiver coil with more turns or a transmitter coil with less turns. |

| + | * We must learn: | ||

* How to use PSpice/MutliSim or some other circuit simulation software to create a schematic of our design and simulate its behavior under different parameters. | * How to use PSpice/MutliSim or some other circuit simulation software to create a schematic of our design and simulate its behavior under different parameters. | ||

| − | * How to use | + | * How to use AutoCad or equivalent 3D design software to design our iPad case and the body of the charging stand. |

| − | + | * How to program on Arduino to implement the safety features described above as well as switching a transistor at a frequency on the order of 10 kHz. | |

| − | * How to program on Arduino | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

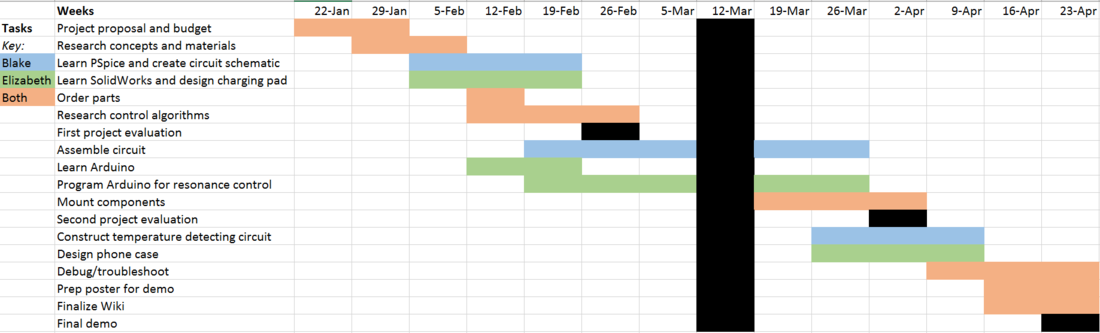

==Gantt Chart== | ==Gantt Chart== | ||

Revision as of 00:11, 14 February 2017

Contents

Blake Bordelon and Elizabeth Onder

Overview

The goal of our project is to create a wireless charging pad capable of transferring power from a base station powered by a Lithium Ion battery to a receiver system that outputs power to a standard port at 5 V and .5 A. The device will consist of a transmitter base and a receiver, each of which will house an inductive coil capable of coupling at close distances. Unlike many wireless chargers on the market, our transmitter base will be powered by a 7.4 V lithium ion battery, rendering our transmitter pad portable. Switching and power delivery will be handled by an Arduino in the transmitter pad. The Arduino will switch a MOSFET transistor at a frequency between 10-20 kHz to allow for the delivery of alternating current to the primary coil. A battery management integrated circuit will be implemented in the transmitter base to prevent excessive spikes in current or voltage across our lithium ion battery. In addition, a LM60 temperature sensing IC will feed into the Arduino to allow for fail safe mechanism should the circuit get too hot. The alternating current in the primary coil should in turn produce a varying magnetic flux through the receiver coil, driving an oscillating current through the receiver. Both coils will be in parallel with capacitors in order to reduce some losses to parasitic impedance. Additional capacitors may be placed to filter the signals and to snub the inductive kickback on the transistor. The current passing through the receiver will then pass through a full bridge rectifier constructed from a diode bridge in parallel with a capacitor. This unregulated DC voltage (hovering around 7-10 V) will then pass through a 7805 Voltage Regulator to produce the desired 5 V output. Because we can control the switching frequency directly with the Arduino, we aim to experiment with our code in order to improve power delivery.

Block Diagram

Objectives

- The objective of this project is to create a working wireless power delivery system as described above. The device should be powered by the Li Ion battery and should be capable of transferring power over the coupled coils from several millimeters distance.

- For the demo, we intend to demonstrate power transfer by lighting an LED with our regulated power on the receiver end. Starting with the receiver module far away from the transmitter and the LED clearly off, we can move the receiver coil closer to the device.

Challenges

- Lithium ion batteries can be dangerous if exposed to high temperatures or large fluctuations in current or voltage. Thus maintaining appropriate and safe conditions for the battery presents a significant challenge. To overcome this challenge, we aim to include a temperature fail safe from our temperature sensing IC as well as a battery management regulator IC. Should the temperature get too high, a switch should open to disconnect the battery from the circuit.

- Another significant challenge is the magnitude of the alternating voltage required in the receiver. The 7805 voltage regulator requires a voltage from ~7-18 V in order to produce the 5 V output. Thus the voltage across the coupled receiver coil must be around this magnitude. If we only use a 7.4 V DC battery on the transmitter side of the system, then we may not produce a high enough voltage on the receiver end to successfully produce a 5 V signal on the other side of the rectifier and 7805 voltage regulator. We may have to choose or design a receiver coil with more turns or a transmitter coil with less turns.

- We must learn:

- How to use PSpice/MutliSim or some other circuit simulation software to create a schematic of our design and simulate its behavior under different parameters.

- How to use AutoCad or equivalent 3D design software to design our iPad case and the body of the charging stand.

- How to program on Arduino to implement the safety features described above as well as switching a transistor at a frequency on the order of 10 kHz.

Gantt Chart

Budget

- Two wireless charging coils: 2 x $8.22 = $16.44 (Link)

- Battery Management IC: $4.50 (Link)

- 7805 Voltage Regulator: $0.95 (Link)

- Temperature Sensor: $0.69 (Link)

- 7.4 V Lithium Ion Battery: Supplied by Class

- 2 3.7 V Li Ion Batteries: Supplied by Class

- Lithium Ion Battery Charger: Supplied by Class

- Breadboard: Supplied by Class

- Arduino: supplied by class

- 3D-printed parts: supplied by class

- MultiSim Circuit simulation software: supplied by school

- MOSFET Transistor: $6.05 (Link)

- Resistors: $0.10+$0.10+$0.1+$0.56+$1.55= $2.41 (Link 1) (Link 2) (Link 3) (Link 4) (Link 5)

- Spark Fun Capacitor Kit: $6.95 (Link)

- Diodes (for Rectifier Bridge): $5.38 (Link)

- LED's: Supplied by Class

Total before tax and shipping: $43.37;