Difference between revisions of "Cheers! Weekly Log"

Jessieshi97 (talk | contribs) |

Jessieshi97 (talk | contribs) |

||

| Line 12: | Line 12: | ||

Haixiang finished the tutorial on Introduction to Solidworks and Tutorial 1. Jessie started drawing pictures for the mechanical design of the system and editing the project proposal page. We realized that 3D printing could only print a maximum length of 6 inches so we decided to print three supportive stands on each side to make a strong base, and each stand will be made out of 2 pieces of 3D printings. | Haixiang finished the tutorial on Introduction to Solidworks and Tutorial 1. Jessie started drawing pictures for the mechanical design of the system and editing the project proposal page. We realized that 3D printing could only print a maximum length of 6 inches so we decided to print three supportive stands on each side to make a strong base, and each stand will be made out of 2 pieces of 3D printings. | ||

| + | == Week 4 (2/13-2/19) == | ||

| + | |||

| + | We decided to change the stepper motor to servo motor so that it would not get so hot when operating at zero speed. Because of the limitation in the torque of the servo motor, we implemented a four pulley system so that we could reduce cut the weight of bottle(with soda) to 1/4 of its original weight as sensed by the motor. In addition we thought it should be best to put the motor in good air ventilated part. | ||

| + | |||

| + | We made a 3D printing for two vertical base and changed some idea for our wooden cover. We will build two vertical base at the top of lumber.(use screw to stabile it). | ||

[[Category:Logs]] | [[Category:Logs]] | ||

[[Category:Spring 2017 Logs]] | [[Category:Spring 2017 Logs]] | ||

Revision as of 19:52, 18 February 2017

Week 1 (1/23 - 1/29)

Formulate group and brainstorm about project ideas. We decided to replicate a beer pouring machine on youtube.

Week 2 (1/30 - 2/5)

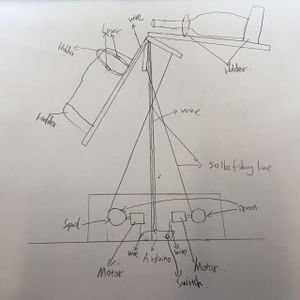

We met with Natalie (TA) to help us straighten the project objective, determine several potential challenges and write out the project proposal. We researched about the specific mechanism to control tilt angles as it was not clearly shown in the video It was decided that we use two 90 degrees lever, each for soda bottle and glassware, tied with a fishing line connected to a spool on a step motor to control the tilt angle (Figure 1). The start for the system is controlled by a push button and the stop pouring signal should be decided by laser detection. Arduino was found to be useful in the process in controlling this process. For a potentially successful project, the budget was determined after objective and challenges were identified.

Week 3 (2/6-2/12)

We compared the pros and cons of various available sensors (distance sensor, color sensor, laser sensor, liquid level sensor and weight sensors) and decided to change our laser sensor to weight sensor. Other sensors all have high chances of electric shock as it is very hard to cover the sensor to prevent liquid damage. Weight sensor could be hidden in the base holder of the glassware and the wires are sent to the Arduino board inside the support stands. In addition, we decided to put a wooden cover on the Arduino board and stepper motor. The fishing line will be sent out from the cover through a little hole and connect to the lever using four pulleys. We together altered the objective in the project proposal to make the mechanical models and its tilting mechanism more robust.

Haixiang finished the tutorial on Introduction to Solidworks and Tutorial 1. Jessie started drawing pictures for the mechanical design of the system and editing the project proposal page. We realized that 3D printing could only print a maximum length of 6 inches so we decided to print three supportive stands on each side to make a strong base, and each stand will be made out of 2 pieces of 3D printings.

Week 4 (2/13-2/19)

We decided to change the stepper motor to servo motor so that it would not get so hot when operating at zero speed. Because of the limitation in the torque of the servo motor, we implemented a four pulley system so that we could reduce cut the weight of bottle(with soda) to 1/4 of its original weight as sensed by the motor. In addition we thought it should be best to put the motor in good air ventilated part.

We made a 3D printing for two vertical base and changed some idea for our wooden cover. We will build two vertical base at the top of lumber.(use screw to stabile it).