Difference between revisions of "Cheers!"

Jump to navigation

Jump to search

Jessieshi97 (talk | contribs) |

Jessieshi97 (talk | contribs) |

||

| Line 1: | Line 1: | ||

== Overview== | == Overview== | ||

| − | Have you ever feel frustrated that the soda liquid line always rises higher than your expectation that it spilled all over your table? We are here to help. 'Cheers' is a automated soda pouring machine that takes a bottled soda and pour it into glassware without spilling the fizz. It utilizes 3D printing techniques for contructing the mechanical framework and Arduino to control the system. 'Cheers' tilts your soda bottle and glass to a | + | Have you ever feel frustrated that the soda liquid line always rises higher than your expectation that it spilled all over your table? We are here to help. 'Cheers' is a automated soda pouring machine that takes a bottled soda and pour it into glassware without spilling the fizz. It utilizes 3D printing techniques for contructing the mechanical framework and Arduino to control the system. 'Cheers' tilts your soda bottle and glass to a angle towards each other to minimize the fizzing and the tilting mechanism will stop after the beer height reached your desired level and voila, Cheers! |

== Team Members == | == Team Members == | ||

| Line 10: | Line 10: | ||

[[File:Fig1.jpeg|thumb|Figure 1]] | [[File:Fig1.jpeg|thumb|Figure 1]] | ||

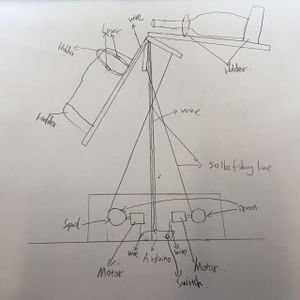

# Replicate the project found on [https://www.youtube.com/watch?v=tyv5rVPUGLU&t=21s youtube] but replace the beer bottle with soda glass bottle and a correct size glassware. There will also be no bottle rotating mechanism. The control for tilting mechanism will be changed to a pulley rope system outlined in Figure 1. | # Replicate the project found on [https://www.youtube.com/watch?v=tyv5rVPUGLU&t=21s youtube] but replace the beer bottle with soda glass bottle and a correct size glassware. There will also be no bottle rotating mechanism. The control for tilting mechanism will be changed to a pulley rope system outlined in Figure 1. | ||

| − | # Glassware can have two angles. Position 1 is | + | # Glassware can have two angles. Position 1 is perpendicular to the table (Figure 2) and position 2 is tilted by an angle to the horizont. Angle is determined through experiments that if the glassware were tilted to that angle and filled without spilling, the liquid will take up approximately 2/3 of the total volume of glassware. |

| − | # Soda bottle should be able to have | + | # Soda bottle should be able to have 3 positions, each is shown in Figures 2, 3 and 4 respectively. The latter two angles will be determined through experiments. Position 2 will be when the first drop of soda occurs and position 3 is when all the soda in bottle could be poured out. |

| − | # There will be | + | # There will be one pouring mechanisms, glassware and soda bottles should both tilt fast from position 1 (Figure 2) to position 2 (Figure 3) (reach this position at the same time). Glassware is kept at position 2 and the soda bottle is tilted very slowly from position 2 to position 3 to pour the soda slowly into the glassware. When the liquid in glassware reached approximately 3 cm to its tip, it will tilt back slowly to position 1 while soda is still pouring. Glassware reaching position 1 and soda bottle reaching position 3 should be at the same time. This is when the pouring mechanism ends, and then the soda bottle will return fast to position 1. |

| − | + | # Weight sensor will be used to estimate the amount of liquid in glassware and thus controls the tilting mechanism. | |

| − | # | ||

# Start of the program is through pressing a push button. | # Start of the program is through pressing a push button. | ||

| − | # | + | # Wood protection cover will be used to on top of the Arduino, motors and spool. Four pulley will be used as shown in Figure 1 to eliminate the chances of electric shock. The wires to connect the weight sensor to the Arduino board will be inside the support stands (Figure 1). |

# The demo will include demonstration on pouring soda using the complete assembled model. | # The demo will include demonstration on pouring soda using the complete assembled model. | ||

| Line 56: | Line 55: | ||

# Power Pro Fishing Braided line – 50 lbs limit: owned | # Power Pro Fishing Braided line – 50 lbs limit: owned | ||

# Magnet Screw Driver tool kit - owned | # Magnet Screw Driver tool kit - owned | ||

| − | # | + | # Wooden base and wooden protection cover - provided |

# buy something for water | # buy something for water | ||

Total: $ 78.82 (recalculate required!!!!!!!!!!!!!!!!!!!) | Total: $ 78.82 (recalculate required!!!!!!!!!!!!!!!!!!!) | ||

Revision as of 03:14, 13 February 2017

Overview

Have you ever feel frustrated that the soda liquid line always rises higher than your expectation that it spilled all over your table? We are here to help. 'Cheers' is a automated soda pouring machine that takes a bottled soda and pour it into glassware without spilling the fizz. It utilizes 3D printing techniques for contructing the mechanical framework and Arduino to control the system. 'Cheers' tilts your soda bottle and glass to a angle towards each other to minimize the fizzing and the tilting mechanism will stop after the beer height reached your desired level and voila, Cheers!

Team Members

- Jessie Shi (Tianjiao): Chemical Engineering, System Engineering ’18

- Haixiang Ren: System Engineering ’18

- Natalie Ng: TA

Objective

- Replicate the project found on youtube but replace the beer bottle with soda glass bottle and a correct size glassware. There will also be no bottle rotating mechanism. The control for tilting mechanism will be changed to a pulley rope system outlined in Figure 1.

- Glassware can have two angles. Position 1 is perpendicular to the table (Figure 2) and position 2 is tilted by an angle to the horizont. Angle is determined through experiments that if the glassware were tilted to that angle and filled without spilling, the liquid will take up approximately 2/3 of the total volume of glassware.

- Soda bottle should be able to have 3 positions, each is shown in Figures 2, 3 and 4 respectively. The latter two angles will be determined through experiments. Position 2 will be when the first drop of soda occurs and position 3 is when all the soda in bottle could be poured out.

- There will be one pouring mechanisms, glassware and soda bottles should both tilt fast from position 1 (Figure 2) to position 2 (Figure 3) (reach this position at the same time). Glassware is kept at position 2 and the soda bottle is tilted very slowly from position 2 to position 3 to pour the soda slowly into the glassware. When the liquid in glassware reached approximately 3 cm to its tip, it will tilt back slowly to position 1 while soda is still pouring. Glassware reaching position 1 and soda bottle reaching position 3 should be at the same time. This is when the pouring mechanism ends, and then the soda bottle will return fast to position 1.

- Weight sensor will be used to estimate the amount of liquid in glassware and thus controls the tilting mechanism.

- Start of the program is through pressing a push button.

- Wood protection cover will be used to on top of the Arduino, motors and spool. Four pulley will be used as shown in Figure 1 to eliminate the chances of electric shock. The wires to connect the weight sensor to the Arduino board will be inside the support stands (Figure 1).

- The demo will include demonstration on pouring soda using the complete assembled model.

- we will attach new picture of the specified glassware and kind of soda bottle by friday and new figure 1, figure 2 (with estimated positions of 2s for bottle and glassware **************

Challenges

- 3D printing

- learn solidworks

- design the soda bottle and glassware holder.

- design two spools that could fit onto the stepper motor to control the rope length.

- Arduino

- Learn Arduino programming language.

- Implementing the Arduino code with laser and adjusting parameters to stable control the tilting mechanism.

- Hardware

- Stepper motor should keep control system stable during tilting mechanism and not going too fast/slow

- Design a circuit that connects the step motor, push button, laser sensor onto Arduino.

- Optimal height of laser pointer should be determined as the glassware is tilted.

- Determine the rpm value on step motor as the spool pulls the fishing line, which controls the tilt angle.

- The soda bottle should be able to tilt an angle more than 90 degrees from its original position.

- Safety

- Electricity hazard when circuit interacts with liquid

- Rope might break

Budget

- Nema 17 Stepper Motor x 2: $24.98

- Color Detector: $9.99

- Load Cell Amplifier HX-711: $9.95

- Load Cell, straight bar 10kg: $6.95

- Wall Adapter Power Supply: $5.69

- Epoxy Glue: $7.28

- Tack Switch Push Button: $1.99 (+$2.69 shipping)

- Extension Cord: $7.99

- Resistor Kit: $9.89

- Screw and Nut: $8.99

- Soda and glassware – $10 from walmart

- Arduino: provided

- 3D printing: provided

- Power Pro Fishing Braided line – 50 lbs limit: owned

- Magnet Screw Driver tool kit - owned

- Wooden base and wooden protection cover - provided

- buy something for water

Total: $ 78.82 (recalculate required!!!!!!!!!!!!!!!!!!!)