Difference between revisions of "Cheers! Weekly Log"

Jessieshi97 (talk | contribs) |

Jessieshi97 (talk | contribs) |

||

| Line 1: | Line 1: | ||

| − | == Week 1 == | + | == Week 1 (1/23 - 1/29)== |

| − | Formulate group and brainstorm about project ideas. | + | Formulate group and brainstorm about project ideas. We decided to replicate a beer pouring machine on [https://www.youtube.com/watch?v=tyv5rVPUGLU&t=21s youtube]. |

| − | == Week 2 == | + | == Week 2 (1/30 - 2/5)== |

| − | + | [[File:Fig1.jpeg|thumb|Figure 1]] | |

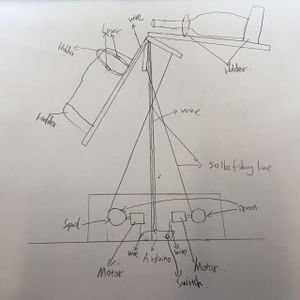

| + | We met with Natalie (TA) to help us straighten the project objective, determine several potential challenges and write out the project proposal. We researched about the specific mechanism to control tilt angles as it was not clearly shown in the [https://www.youtube.com/watch?v=tyv5rVPUGLU&t=21s video] It was decided that we use two 90 degrees lever, each for soda bottle and glassware, tied with a fishing line connected to a spool on a step motor to control the tilt angle (Figure 1). The start for the system is controlled by a push button and the stop pouring signal should be decided by laser detection. Arduino was found to be useful in the process in controlling this process. For a potentially successful project, the budget was determined after objective and challenges were identified. | ||

[[Category:Logs]] | [[Category:Logs]] | ||

[[Category:Spring 2017 Logs]] | [[Category:Spring 2017 Logs]] | ||

Revision as of 22:26, 3 February 2017

Week 1 (1/23 - 1/29)

Formulate group and brainstorm about project ideas. We decided to replicate a beer pouring machine on youtube.

Week 2 (1/30 - 2/5)

We met with Natalie (TA) to help us straighten the project objective, determine several potential challenges and write out the project proposal. We researched about the specific mechanism to control tilt angles as it was not clearly shown in the video It was decided that we use two 90 degrees lever, each for soda bottle and glassware, tied with a fishing line connected to a spool on a step motor to control the tilt angle (Figure 1). The start for the system is controlled by a push button and the stop pouring signal should be decided by laser detection. Arduino was found to be useful in the process in controlling this process. For a potentially successful project, the budget was determined after objective and challenges were identified.