Difference between revisions of "Visual Beats Log"

| (11 intermediate revisions by 2 users not shown) | |||

| Line 16: | Line 16: | ||

===10/21/2016=== | ===10/21/2016=== | ||

| − | Our exciter and amplifier worked perfectly together! We were able to set up a prototype of our design using a corrugated plastic plate we bought and random PVC scraps available to salvage and use. We set up the plate and attached the exciter to it with duct tape, not the perfect design but we wanted to create a quick set up in order to see what our challenges will be when finalizing the design. Unfortunately, we weren't able to find a symmetrical design but this was because the plate wasn't leveling properly while attached to the exciter. Another thing to note was that at max amp volume, we were only able to get physical vibration under ~800Hz. We deduced that this is because of the way the corrugated plastic plate is formed and believe the aluminum plate will manage better results. We plan on extending our experimenting to a week in order to finalize on the design, use the aluminum plate, and make sure the plate is leveled properly. | + | Our exciter and amplifier worked perfectly together! We were able to set up a prototype of our design using a corrugated plastic plate we bought and random PVC scraps available to salvage and use. We set up the plate and attached the exciter to it with duct tape, not the perfect design but we wanted to create a quick set up in order to see what our challenges will be when finalizing the design. |

| − | + | [[File:Vbcorrugatedplastic.mov|400px|thumb|upright|Here is a quick video of a trial at 440Hz]] | |

| − | + | Unfortunately, we weren't able to find a symmetrical design but this was because the plate wasn't leveling properly while attached to the exciter. Another thing to note was that at max amp volume, we were only able to get physical vibration under ~800Hz. We deduced that this is because of the way the corrugated plastic plate is formed and believe the aluminum plate will manage better results. We plan on extending our experimenting to a week in order to finalize on the design, use the aluminum plate, and make sure the plate is leveled properly. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | ===10/28/2016=== | ||

| + | For the Arduino: | ||

| + | We have connected a button to the breadboard which is ready for use once we finally put together our mechanical design this weekend. For the doing part, we mainly use the syntax "tone", which generates a square wave of the specified frequency (and 50% duty cycle) on a pin. A duration can be specified, otherwise the wave continues until a call to "noTone()". The pin can be connected to a speaker/DAC to play tones. Our board can generate from a frequency range of 31 Hz to 65535 Hz (although we will only be using 100 to 1k Hz). | ||

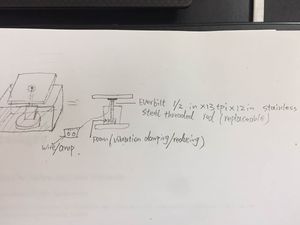

| + | [[File:Design.jpg|thumb|upleft|Rough sketch of new design]] | ||

| + | For our final mechanical design: | ||

| + | We have tested several ways to connect our plate to the exciter, and the exciter to the supporting platform. For the first part, plate to the exciter, we can simply use some tape or glue to make them attached to each other. The point is it will give us decent sand patterns if both elements are directly attached. To optimize the sand pattern, the exciter should be placed, and measured at the center of the plate, so that the patterns will be symmetrical. | ||

| + | For the second part, it took us some time to test and find the way to install the platform and attach the exciter(plate) to it, which will ideally help generate the decent patterns and stable enough so that it won’t lean to any side while vibrating. In the end, we decide to use a rod with threaded end to stick in to the exciter and connect it to the platform. Our solutions are, first, we can make the rod comparatively short, so that the torque will be lower and the plate will be more likely to remain balanced; second, using a foam to the wrap the connecting part of rod and the platform to damp/reduce the vibration effect to the platform. One benefit of doing this will be it makes us easier to adjust. However, it has not been tested during experiment. We are getting the desirable stuff from stores around the city this weekend to improve our project mechanically. | ||

| + | ===11/04/2016=== | ||

| + | We finished our final mechanical design this week and super glued our aluminum plate to the exciter. After some testing, we found 5 frequencies that resulted in nice decent patterns. Our best pattern came from 528Hz creating a butterfly-like shape out of 4 squares. | ||

| + | [[File:528hz.jpeg|thumb|upright]] | ||

| + | We tried out a melody we found on youtube that was said to be also "528Hz" and it gave us a pattern that was very different to the butterfly (no symmetry/ set of lines and circles). Our only downside is that the plate didn't end up leveling that way we wanted it to. This has shown to affect the simpler shapes we tried to form as it was clear one side of the plate had more sand built up than the other sides. Our next mission is to set up our Arduino/DAC circuit and find a way to solve the balancing problem. | ||

| + | ===11/11/2016=== | ||

| + | We have the DAC and button hooked up and ready for testing. Li will be spending this weekend testing it with the Arduino alongside figuring out how to use one of the buttons to control the on/off of the DAC. We are beginning to get behind with the mechanical as we have been contemplating how to deal with 3 main issues with it. 1st: Dealing with the noise of the plate, 2nd: balancing the plate, 3rd: having a strong base to hold the exciter and plate down. Since our apparatus functions well as it is, we believe priority must take place with dealing with the noise (this also is the most significant change since we could lose the accuracy of the patterns formed by using dampeners). After a brief discussion with Dr. Peters, we have concluded to try placing elastomeric pads between the coil structure and black plate of the exciter. We have also been investigating harmonics and figuring out what filter might be the best to use. A low pass filter currently seems to be ideal, but we need to do more research and organize a plan on what variations of harmonics we will be experimenting synthesis with. | ||

| + | ===11/18/2016=== | ||

| + | We have just received our two elastomeric padded screws and plan on placing them on corners under the aluminum plate using steel couplings to elevate them. Also, since we will have control of how far both padded screws extend from the coupling, we can rebalance the plate. The DAC/Arduino are working fine so far and we also have a potentiometer connected. We are mainly waiting for the RCA converter to show up in order to test the circuit with the plate. After we attach the pads this weekend, we will record the shapes again in order to see how much the pads/readjustment influence the standing waves. | ||

| − | === | + | ===11/22/2016=== |

| + | This week, we drilled and placed two dampeners between the wooden platform and aluminum plate in order to cancel out some of the noise and balance the plate. Next week, we plan to connect the Arduino/DAC to the plate and start recording the patterns. | ||

| − | + | ===12/3/2016=== | |

| − | + | Our last piece (the breakout board for an auxiliary cord) of the Arduino set up arrived on Friday and we are having trouble connecting it as there is limited information online for us to follow. We plan on talking to Li's TA (who recommended the breakout board) from his CSE132 class to help us connect it. We emailed him this morning, but if he doesn't respond, Li plans to go into his TA hours tomorrow. We are also currently working on the poster and taking pictures of a few significant patterns we plan to present on demo day. | |

| − | |||

| − | |||

| + | ===12/9/2016=== | ||

| + | The demo went well except at the start when people wanted to see the different patterns we presented on the poster. We only coded the potentiometer to perform 2 patterns (one based off a melody and another the 528 Hz). Thankfully, it took us only a few minutes to add the extra patterns that people wanted to see. | ||

[[Category:Logs]] | [[Category:Logs]] | ||

[[Category:Fall 2016 Logs]] | [[Category:Fall 2016 Logs]] | ||

Latest revision as of 22:51, 9 December 2016

Welcome to the Log!

Contents

9/23/2016

This week we established our schematic of visual-beats and has worked on the proposal. Instead of simply generating frequencies from speaker/amplifier, we decide to connect a xylophone to the Arduino board. So that we can see different patterns generated from different xylophone musics. We talked with our TA, Will about the theoretical feasibility and other potential improvements.

9/30/2016

We are in the process of completing multiple sketches and finalizing our plan before purchasing items. We are working on laying out a detailed process of the piezo signal transmission from GarageBand to the Amplifier and the figuring out the computation of the Kirchoff-Love Plate theory into 3-D Models. We might be choosing to use a smaller speaker, but need to do more research in order to understand the level of sound we will be working with. We have considered using surface transducers/oscillator motors, but since we would rather have an output that plays music, we chose to stick with an optimal speaker. Understanding the audio engineering to how speakers work is a must before we begin building anything.

10/07/2016

We spent this week "coming down to Earth" with our ideas and decided to let go of the xylophone as our project is already dense without it. Instead of using a speaker and having to hassle with connecting its coil to the plate, we found an object called the Exciter which is an electromagnetic coil used to impact sound on plates. This caused our prototype model to be rearranged with new materials as well, which you can view from our wiki page.

Our plan with the Arduino is to connect a DAC to the Arduino board so the digital signal would be converted to analog signal. Then we "amplify" the signal by connecting an amp to the DAC.

10/14/2016

For now, we've decided to place our plate/speaker set up into a cardboard box so that we won't make a mess for our experiments next week. We hope to find a better way to catch the sand, but our ideas all require us to attach material to our plate. We do not know if this will mess up our chances with gaining patterns and so we decided to keep our set up as simple as possible and slowly build from what works. We have obtained our amplifier and have tested it to make sure it was in good condition. We also decided that we will use corrugated plastic just for our prototype, but will eventually replace it with an aluminum plate. We need the exciter and plate to be placed over something and we chose to use a pvc pipe that is slightly smaller in radius than the exciter and 3-4 inches in length. We plan on connecting the pipe to the exciter with adhesives and the other end of the pipe to ply wood. We aren't sure how stable the plate will be in this format, hence why we decided to start with the corrugated plastic rather than jumping to the aluminum plate.

10/21/2016

Our exciter and amplifier worked perfectly together! We were able to set up a prototype of our design using a corrugated plastic plate we bought and random PVC scraps available to salvage and use. We set up the plate and attached the exciter to it with duct tape, not the perfect design but we wanted to create a quick set up in order to see what our challenges will be when finalizing the design.

Unfortunately, we weren't able to find a symmetrical design but this was because the plate wasn't leveling properly while attached to the exciter. Another thing to note was that at max amp volume, we were only able to get physical vibration under ~800Hz. We deduced that this is because of the way the corrugated plastic plate is formed and believe the aluminum plate will manage better results. We plan on extending our experimenting to a week in order to finalize on the design, use the aluminum plate, and make sure the plate is leveled properly.

10/28/2016

For the Arduino: We have connected a button to the breadboard which is ready for use once we finally put together our mechanical design this weekend. For the doing part, we mainly use the syntax "tone", which generates a square wave of the specified frequency (and 50% duty cycle) on a pin. A duration can be specified, otherwise the wave continues until a call to "noTone()". The pin can be connected to a speaker/DAC to play tones. Our board can generate from a frequency range of 31 Hz to 65535 Hz (although we will only be using 100 to 1k Hz).

For our final mechanical design: We have tested several ways to connect our plate to the exciter, and the exciter to the supporting platform. For the first part, plate to the exciter, we can simply use some tape or glue to make them attached to each other. The point is it will give us decent sand patterns if both elements are directly attached. To optimize the sand pattern, the exciter should be placed, and measured at the center of the plate, so that the patterns will be symmetrical. For the second part, it took us some time to test and find the way to install the platform and attach the exciter(plate) to it, which will ideally help generate the decent patterns and stable enough so that it won’t lean to any side while vibrating. In the end, we decide to use a rod with threaded end to stick in to the exciter and connect it to the platform. Our solutions are, first, we can make the rod comparatively short, so that the torque will be lower and the plate will be more likely to remain balanced; second, using a foam to the wrap the connecting part of rod and the platform to damp/reduce the vibration effect to the platform. One benefit of doing this will be it makes us easier to adjust. However, it has not been tested during experiment. We are getting the desirable stuff from stores around the city this weekend to improve our project mechanically.

11/04/2016

We finished our final mechanical design this week and super glued our aluminum plate to the exciter. After some testing, we found 5 frequencies that resulted in nice decent patterns. Our best pattern came from 528Hz creating a butterfly-like shape out of 4 squares.

We tried out a melody we found on youtube that was said to be also "528Hz" and it gave us a pattern that was very different to the butterfly (no symmetry/ set of lines and circles). Our only downside is that the plate didn't end up leveling that way we wanted it to. This has shown to affect the simpler shapes we tried to form as it was clear one side of the plate had more sand built up than the other sides. Our next mission is to set up our Arduino/DAC circuit and find a way to solve the balancing problem.

11/11/2016

We have the DAC and button hooked up and ready for testing. Li will be spending this weekend testing it with the Arduino alongside figuring out how to use one of the buttons to control the on/off of the DAC. We are beginning to get behind with the mechanical as we have been contemplating how to deal with 3 main issues with it. 1st: Dealing with the noise of the plate, 2nd: balancing the plate, 3rd: having a strong base to hold the exciter and plate down. Since our apparatus functions well as it is, we believe priority must take place with dealing with the noise (this also is the most significant change since we could lose the accuracy of the patterns formed by using dampeners). After a brief discussion with Dr. Peters, we have concluded to try placing elastomeric pads between the coil structure and black plate of the exciter. We have also been investigating harmonics and figuring out what filter might be the best to use. A low pass filter currently seems to be ideal, but we need to do more research and organize a plan on what variations of harmonics we will be experimenting synthesis with.

11/18/2016

We have just received our two elastomeric padded screws and plan on placing them on corners under the aluminum plate using steel couplings to elevate them. Also, since we will have control of how far both padded screws extend from the coupling, we can rebalance the plate. The DAC/Arduino are working fine so far and we also have a potentiometer connected. We are mainly waiting for the RCA converter to show up in order to test the circuit with the plate. After we attach the pads this weekend, we will record the shapes again in order to see how much the pads/readjustment influence the standing waves.

11/22/2016

This week, we drilled and placed two dampeners between the wooden platform and aluminum plate in order to cancel out some of the noise and balance the plate. Next week, we plan to connect the Arduino/DAC to the plate and start recording the patterns.

12/3/2016

Our last piece (the breakout board for an auxiliary cord) of the Arduino set up arrived on Friday and we are having trouble connecting it as there is limited information online for us to follow. We plan on talking to Li's TA (who recommended the breakout board) from his CSE132 class to help us connect it. We emailed him this morning, but if he doesn't respond, Li plans to go into his TA hours tomorrow. We are also currently working on the poster and taking pictures of a few significant patterns we plan to present on demo day.

12/9/2016

The demo went well except at the start when people wanted to see the different patterns we presented on the poster. We only coded the potentiometer to perform 2 patterns (one based off a melody and another the 528 Hz). Thankfully, it took us only a few minutes to add the extra patterns that people wanted to see.