Difference between revisions of "BetaDelta Log"

Jump to navigation

Jump to search

| Line 78: | Line 78: | ||

**[[File:Pick4.jpg]] | **[[File:Pick4.jpg]] | ||

**[[File:Pick3.jpg]] | **[[File:Pick3.jpg]] | ||

| − | |||

| − | |||

**3D printed (to a reduced scale) the first version of the case: | **3D printed (to a reduced scale) the first version of the case: | ||

**[[File:Pick10.jpg]] | **[[File:Pick10.jpg]] | ||

| Line 88: | Line 86: | ||

'''Week of March 24, 2017''' | '''Week of March 24, 2017''' | ||

*Team: met and put the code for the motion sensor into the raspberry pi using python. We are working on the final steps to getting our server running, dealing with the issue of an encrypted wifi path. | *Team: met and put the code for the motion sensor into the raspberry pi using python. We are working on the final steps to getting our server running, dealing with the issue of an encrypted wifi path. | ||

| + | **[[File:pic3.jpg]] | ||

*Nial: | *Nial: | ||

**Connected wifi dongle to the Wustl internet. | **Connected wifi dongle to the Wustl internet. | ||

*Bex: | *Bex: | ||

**Printed the to-scale version of the casing. We found that all pieces fit relatively well into the case, but are going to make a few adjustments to allow the motion sensor to protrude further out from the case as well as have the sound detector have a better-fitted box. A hole was also added for the power supply, which was mistakenly forgotten in the first versions of the model. A second piece will be printed, the wall mount, and superglued to the rectangular case that holds the raspberry pi and sensors itself. Two pieces are necessary because the 3D printers are limited in the size of model they can print at a time. A picture of the first to-scale model is below: | **Printed the to-scale version of the casing. We found that all pieces fit relatively well into the case, but are going to make a few adjustments to allow the motion sensor to protrude further out from the case as well as have the sound detector have a better-fitted box. A hole was also added for the power supply, which was mistakenly forgotten in the first versions of the model. A second piece will be printed, the wall mount, and superglued to the rectangular case that holds the raspberry pi and sensors itself. Two pieces are necessary because the 3D printers are limited in the size of model they can print at a time. A picture of the first to-scale model is below: | ||

| − | + | **[[File:Pic2.jpg]] | |

| + | **[[File:Pic1.jpg]] | ||

*JD: Connected the wifi dongle to the raspberry pi. | *JD: Connected the wifi dongle to the raspberry pi. | ||

Revision as of 21:12, 31 March 2017

Week of January 27, 2017

- Brainstormed project ideas

- Our main focus was on a website that provides realtime updates about the availability of South 40 study rooms

- Held first meeting with our TA

- Began work on our proposal

Week of February 3, 2017

- Met with TA to finalize our project idea as well as work on some of its highlights

- Highlights that we decided we would like to include:

- User input ability, where students can publicize which subjects are being studied in specific study rooms

- The detection of room occupation via light sensor

- A history log of past room availabilities, so that students can make predictions for future study plans

- Finished writing the proposal as a team

Week of February 10, 2017

- Refined proposal

- Edited Gantt chart and budget

- Team decisions:

- Add both motion and sound detectors to the light sensor, all of which will be hooked up to our raspberry pi

- This will allow more accurate prediction on whether or not the room is occupied

- Add both motion and sound detectors to the light sensor, all of which will be hooked up to our raspberry pi

- Began learning how to code in python

- Began brainstorming design ideas for Raspberry Pi casing

- Official design must wait until materials arrive

Week of February 17, 2017

- Edited Gantt chart and budget

- Worked on recommendations from our TA about our proposal:

- Streamlined our objectives

- Continued python education

- Edited design for Raspberry Pi casing

- Still waiting on materials to be ordered and shipped

Week of February 24, 2017

- Heavy exam week for systems engineers (includes all three team members)

- Downloaded Google SketchUp for 3D printing design and began learning how it works

- Continued brainstorming ideas for raspberry pi casing

- Continued learning python

- Obtained our raspberry pi

Week of March 3, 2017

- Added a highlight to the BetaDelta website: users can now see a ranking of study rooms based on their probability of being available

- Discussed how the website will display information for each study room

- Light sensor: "on" or "off"

- Motion and sound sensor - will report most recent indication of activity

- Edited our budget:

- Included the specific website host for BetaDelta

- Got rid of the ethernet cord (using a wifi dongle instead)

Week of March 10, 2017

- Bex:

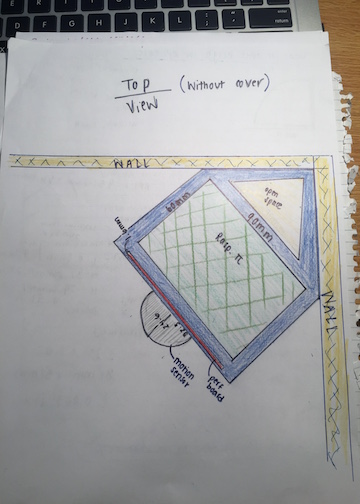

- drew final draft of device casing.

- Top View:

- The rectangular shape holds the raspberry pi in the bottom of the casing and the perf board built into the wall, with holes for each sensor to protrude.

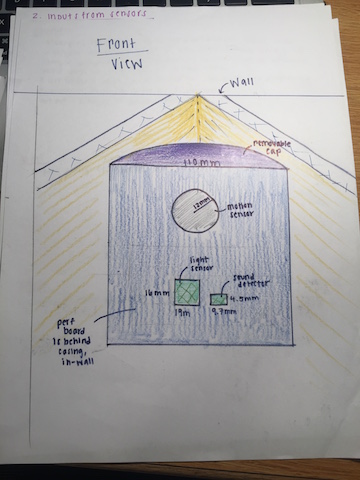

- Front View:

- The motion sensor is at the top, with the light and sound sensors below.

- Practiced drawing a wine bottle in sketchup:

- Converted drawing into a 3D model in sketchup

- Created first outline for an algorithm. 5 necessary steps have emerged for the algorithm.

- Before entering the algorithm:

- Convert information from sensors into comparable numbers

- Assign those numbers to a temporary variable

- In algorithm:

- Enter a conditional loop.

- If motion sensor is activated within the last 15 minutes, the room is occupied.

- If the light sensor and the sound sensor have both been activated within the last 5 minutes, the room is occupied.

- Else, the room is NOT occupied.

- Exit loop and refetch data.

- Before entering the algorithm:

- Created first outline for an algorithm. 5 necessary steps have emerged for the algorithm.

Week of March 17, 2017

- Bex:

- Ran into issues converting sketchup file to an STL, so the solution was to redrew the sketchup model in CAD with more accurate lines and measurements.

- In CAD:

- JD:

- Drew design for simulation box. We realized as a team that our simulation environment would need to support an easy way to turn a light on and off within the box, stop and start music, and have motion within the box while both other variables are negative (lights off, no sound) to show the first way that our algorithm loop breaks. Also built the circuit for the motion sensor and worked on its connection to the raspberry pi.

- Nial: worked on server and connection to instance.

Week of March 24, 2017

- Team: met and put the code for the motion sensor into the raspberry pi using python. We are working on the final steps to getting our server running, dealing with the issue of an encrypted wifi path.

- Nial:

- Connected wifi dongle to the Wustl internet.

- Bex:

- Printed the to-scale version of the casing. We found that all pieces fit relatively well into the case, but are going to make a few adjustments to allow the motion sensor to protrude further out from the case as well as have the sound detector have a better-fitted box. A hole was also added for the power supply, which was mistakenly forgotten in the first versions of the model. A second piece will be printed, the wall mount, and superglued to the rectangular case that holds the raspberry pi and sensors itself. Two pieces are necessary because the 3D printers are limited in the size of model they can print at a time. A picture of the first to-scale model is below:

- JD: Connected the wifi dongle to the raspberry pi.