Product: ABAQUS/Standard

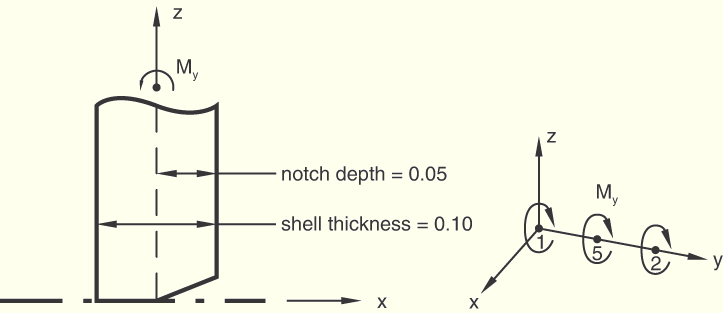

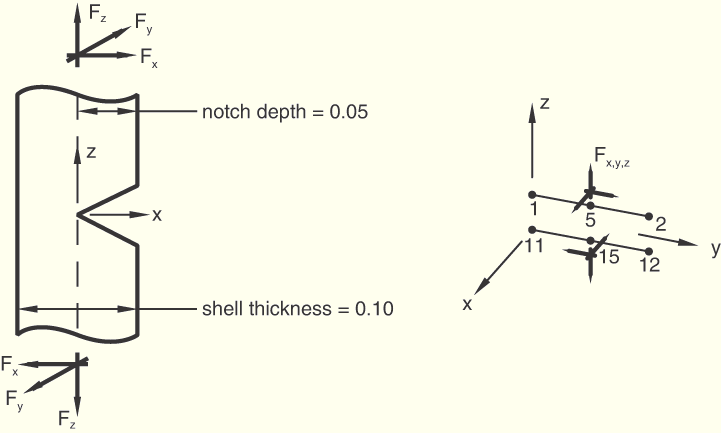

*ELEMENT, TYPE=LS3S, ELSET=ALL 1, 2, 5, 1 *SURFACE FLAW, SIDE=POSITIVE 1, .05 5, .05 2, .05 *SHELL SECTION, MAT=M1, ELSET=ALL .1,Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0.

Boundary conditions:

![]() 0 at nodes 1, 2, and 5.

0 at nodes 1, 2, and 5.

Loading:

M![]() –1.0 at nodes 1 and 2. M

–1.0 at nodes 1 and 2. M![]() –4.0 at node 5.

–4.0 at node 5.

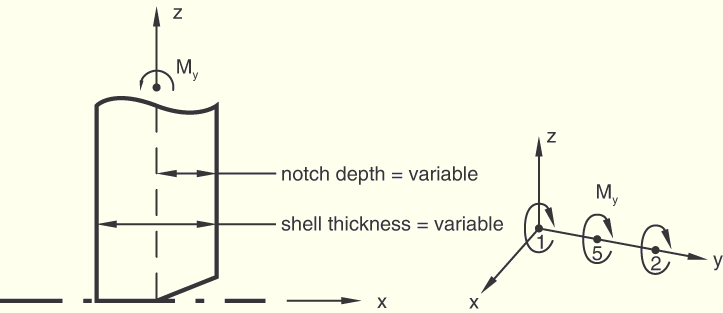

*ELEMENT, TYPE=LS3S, ELSET=ALL 1, 2, 5, 1 *SURFACE FLAW, SIDE=POSITIVE 1, .07 5, .05 2, .04 *SHELL SECTION, MAT=M1, ELSET=ALL, NODAL THICKNESS 99, *NODAL THICKNESS 1, 0.7 5, 0.5 2, 0.4 3, 0.1 4, 0.1 6, 0.1 7, 0.1 8, 0.1Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0.

Boundary conditions:

![]() 0 at nodes 1, 2, and 5.

0 at nodes 1, 2, and 5.

Loading:

M![]() –1.0 at nodes 1 and 2. M

–1.0 at nodes 1 and 2. M![]() –4.0 at node 5.

–4.0 at node 5.

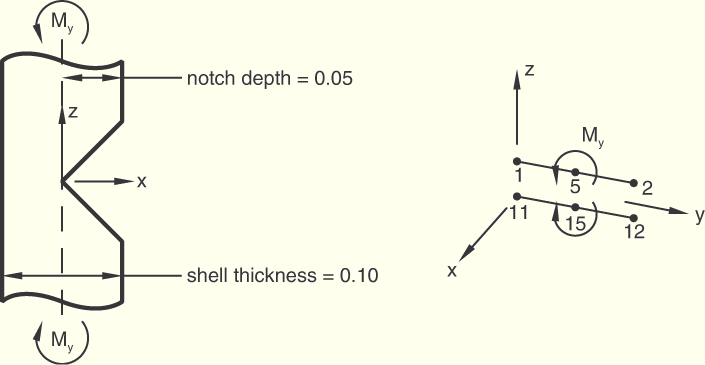

*ELEMENT, TYPE=LS6, ELSET=ALL 1, 2, 5, 1, 12, 15, 11 *SURFACE FLAW, SIDE=POSITIVE 1, .05 5, .05 2, .05 *SHELL SECTION, MAT=M1, ELSET=ALL .1,Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0.

Boundary conditions:

Node 17 is fully constrained. ![]() 0 for all nodes. Nodes 1, 2, and 5 are constrained to move together. Nodes 11, 12, and 15 are constrained to move together.

0 for all nodes. Nodes 1, 2, and 5 are constrained to move together. Nodes 11, 12, and 15 are constrained to move together.

Loading:

M![]() –6.0 at node 5. M

–6.0 at node 5. M![]() 6.0 at node 15.

6.0 at node 15.

Single-edge notch strip under far-field bending about an axis (along the crack-tip line).

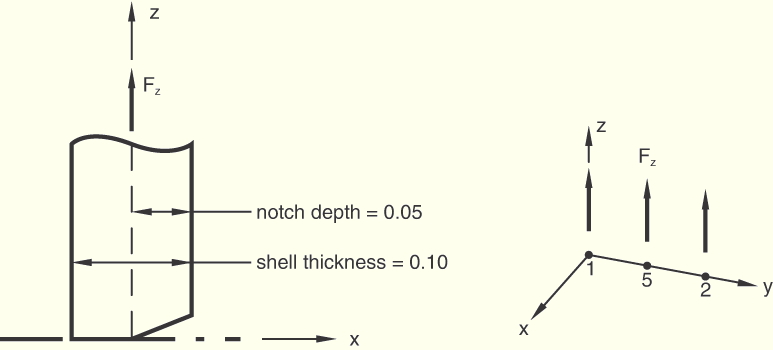

*ELEMENT, TYPE=LS3S, ELSET=ALL 1, 2, 5, 1 *SURFACE FLAW, SIDE=POSITIVE 1, .05 5, .05 2, .05 *SHELL SECTION, MAT=M1, ELSET=ALL .1,Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0.

Boundary conditions:

![]() 0 at nodes 1, 2, and 5.

0 at nodes 1, 2, and 5.

Loading:

F![]() 1.0 at nodes 3 and 4. F

1.0 at nodes 3 and 4. F![]() 4.0 at node 7.

4.0 at node 7.

*ELEMENT, TYPE=LS6, ELSET=ALL 1, 2, 5, 1, 12, 15, 11 *SURFACE FLAW, SIDE=POSITIVE 1, .05 5, .05 2, .05 *SHELL SECTION, MAT=M1, ELSET=ALL .1,Material:

Linear elastic, Young's modulus = 1.0, Poisson's ratio = 0.0.

Boundary conditions:

Node 17 is fully constrained. ![]() 0 for all nodes. Nodes 1, 2, and 5 are constrained to move together. Nodes 11, 12, and 15 are constrained to move together.

0 for all nodes. Nodes 1, 2, and 5 are constrained to move together. Nodes 11, 12, and 15 are constrained to move together.

Loading:

![]() 1.0 at node 5.

1.0 at node 5. ![]() –1.0 at node 15.

–1.0 at node 15.

Single-edge notch strip under far-field tension (Mode I), in-plane shear (Mode II), and uniform out-of-plane shear (Mode III).