Product: ABAQUS/Standard

Simple beam models are used to verify unidirectional, cylindrical, and spherical gap elements.

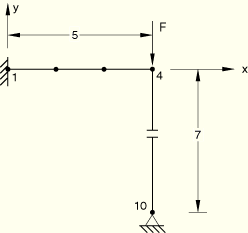

GAPUNI with positive gap clearance:

GAP data: Initial clearance = 0.5.

X, Y, Z direction cosine of the closure direction = (0., –1., 0.).

Boundary conditions: node 1 is clamped, and node 10 is fixed in the x- and y-directions.

Loading case 1: ![]() = –50 at node 4; Loading case 2:

= –50 at node 4; Loading case 2: ![]() = –100 at node 4.

= –100 at node 4.

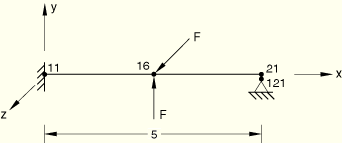

GAPCYL with positive gap clearance:

GAP data: Initial clearance = 0.0208 (positive gap clearance).

X, Y, Z direction cosine of the cylinder axis = (1., 0., 0.).

Boundary conditions: node 11 is clamped, node 121 is fixed in the x-, y- and z-directions.

Loading: Step 1: ![]() = 2.0 × 104 at node 16; Step 2:

= 2.0 × 104 at node 16; Step 2: ![]() = 3.0 × 104 at node 16.

= 3.0 × 104 at node 16.

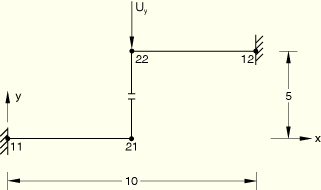

GAPCYL with negative gap clearance:

GAP data: Initial clearance = –1.0 (negative gap clearance).

X, Y, Z direction cosine of the cylinder axis = (1., 0., 0.).

Boundary conditions: nodes 11 and 12 are clamped, ![]() = –5.0 at node 22.

= –5.0 at node 22.

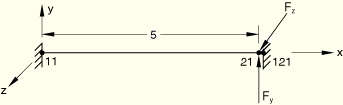

GAPSPHER with positive gap clearance:

GAP data: Initial clearance = 0.2080.

Boundary conditions: nodes 11 and 121 are clamped.

Loading case 1: ![]() = 2.0 × 104 and

= 2.0 × 104 and ![]() = 3.0 × 104 at node 21; Loading case 2:

= 3.0 × 104 at node 21; Loading case 2: ![]() = 4.0 × 104 and

= 4.0 × 104 and ![]() = 6.0 × 104 at node 21. The NLGEOM parameter is used.

= 6.0 × 104 at node 21. The NLGEOM parameter is used.

GAPUNI element with positive gap clearance, perturbation step with *LOAD CASE.

GAPCYL element with positive gap clearance.

GAPCYL element with negative gap clearance.

GAPSPHER element with positive gap clearance, perturbation step with *LOAD CASE.