Products: ABAQUS/Standard ABAQUS/Explicit

DSAX1 DSAX2 DS3 DS4 DS6 DS8 DCAX8 DC3D20

SAX1 SAX2 STRI65 S4R5 S8R5

CAX8R C3D20R

SAX2T S8RT CAX8RT CGAX8RT C3D20RT

Steady-state conditions are assumed in the ABAQUS/Standard simulation. A transient simulation is performed in ABAQUS/Explicit. The total simulation time is 0.4 seconds. This provides enough time for the transient solution to reach steady-state conditions in this problem. Mass scaling is used to reduce the computational cost of the ABAQUS/Explicit analyses.

Material:| Density | 7800 kg/m3 |

| Conductivity | 52 J/ms °C |

| Specific heat | 586 J/kg °C |

| Thermal expansion coefficient | 1.2 × 10–5 |

| Young's modulus | 200 × 103 MPa |

| Poisson's ratio | 0.3 |

Boundary conditions:

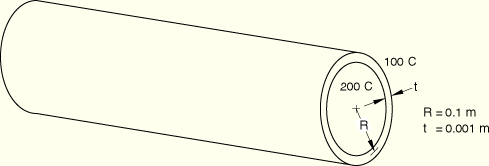

For the thermal analyses the temperatures of the inside and outside surfaces are prescribed to be 200°C and 100°C, respectively. For the stress analyses the rotation vector in the circumferential direction is constrained, but the cylinder is free to expand axially. For the continuum element meshes equations are used to provide the rotational constraints. For the nonaxisymmetric cases symmetrical constraints are applied in the circumferential direction to model the complete cylinder.

In the ABAQUS/Explicit simulations the temperatures are applied gradually to ensure a quasi-static response.

For all of the analyses except those using the coupled temperature-displacement elements (SAX2T, S8RT, CAX4RT, CAX4RHT, CGAX4RT, CGAX4RHT, CAX8RT, CGAX8RT, and C3D20RT in ABAQUS/Standard and CAX3T, CAX4RT, C3D4T, C3D6T, and C3D8RT in ABAQUS/Explicit), the analyses are run in pairs: a thermal analysis followed by its corresponding stress analysis.

Gauss integration is used for the shell cross-section for input file es54sxsj.inp.

The temperature distribution through the thickness of the cylinder is given by

![]()

The analytical solution for the stresses is given in Chapter 15 of “Theory of Plates and Shells,” second edition, by Timoshenko and Woinowsky-Krieger. The stresses at the outer and inner surfaces are given by

![]()

This gives a theoretical stress of 171.43 MPa.

The axisymmetric and second-order shell elements agree exactly with the theory. The first-order three-dimensional shells (S4R5) show an error of –5.1%. The continuum elements show small discrepancies (< 1%) from the reference solution.

The results obtained with ABAQUS/Explicit are in close agreement with those obtained with ABAQUS/Standard.

DSAX1 elements.

DSAX2 elements.

DS3 elements.

DS4 elements.

DS6 elements.

DS8 elements.

DCAX8 elements.

DC3D20 elements.

SAX1 elements.

SAX2 elements.

STRI65 elements.

S4R5 elements.

S8R5 elements.

CAX8R elements.

C3D20R elements.

SAX2T elements.

S8RT elements.

CAX4RT elements.

CAX4RHT elements.

CGAX4RT elements.

CGAX4RHT elements.

CAX8RT elements.

CGAX8RT elements.

C3D20RT elements.

CAX3T elements.

CAX4RT elements.

C3D4T elements.

C3D6T elements.

C3D8RT elements.