You can use the Partition toolset to divide parts or independent part instances into smaller regions. There are three reasons to create partitions in the Mesh module:

To divide a complex, three-dimensional part or instance into simpler regions that ABAQUS/CAE can mesh using primarily hexahedral elements with the structured or swept meshing techniques. (Almost all three-dimensional parts are meshable using the free meshing technique, but three-dimensional free meshes can include only tetrahedral elements.)

To gain more control over mesh generation.

To obtain regions to which you can assign different element types.

You can partition only parts or independent part instances. If you need to partition a dependent instance, you can partition the original part from which the dependent instance was created. Alternatively, you can create a copy of the original part and then create an independent instance of the copy. You can then replace the dependent instance with the new independent instance and partition the independent instance. For more information, see “What is the difference between a dependent and an independent part instance?,” Section 13.3.2.

By default, the free meshing technique with quadrilateral elements is applied to all two-dimensional parts and part instances. When you create the mesh using this default technique, ABAQUS/CAE implicitly creates partitions that divide the part into regions that can be meshed using the structured meshing technique. (For more information, see “Free meshing with quadrilateral and quadrilateral-dominated elements,” Section 17.9.2.) Therefore, all two-dimensional parts are meshable without any manual partitioning.

However, when a three-dimensional part or instance is unmeshable using hexahedral elements, you must take one of the following steps:

Change the element shape from hexahedra to tetrahedra so that the free meshing technique can be applied.

Partition into structured- or swept-meshable regions.

Even when a part or instance can be meshed without partitioning, you may still want to partition to gain more control over mesh generation. Without partitions, the mesh is aligned only along the exterior edges; with partitions, the resulting mesh will have rows or grids of elements aligned along the partitions. That is, the mesh “flows” along the partitions. For example, in Figure 17–24 the partition that divides the rectangle in two causes the mesh to flow at an angle along the partition.

You can use the additional edges created by partitioning a face to control the mesh characteristics. For example, Figure 17–25 illustrates how a partition and local mesh seeds allow you to control the mesh flow and density.

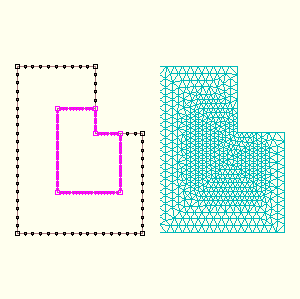

Similarly, Figure 17–26 shows how partitioning and local mesh seeds allow you to refine the mesh in the area of a stress concentration.Figure 17–26 Partitioning and local mesh seeds allow you to refine the mesh in the area of a stress concentration.

When partitioning, remember that partitions will become element boundaries. Therefore, try to ensure that partitions make angles as close to 90° as possible with other partitions or edges. In addition, you should avoid creating unwanted short edges that will distort the mesh.