Products: ABAQUS/Standard ABAQUS/Explicit

Two indentation problems are considered: a square plate of polyurethane foam indented by a rigid, cylindrical punch and a cylindrical plate of the same kind of foam indented by a rigid, hemispherical punch. The examples illustrate a typical application of crushable foam materials used as energy absorption devices. The effect of rate dependence of the foam is shown. Results are presented for ABAQUS/Standard and for both the isotropic and volumetric hardening foam models in ABAQUS/Explicit.

The model consists of a rigid impactor and a deformable plate made of polyurethane foam. The undeformed square plate is 30 mm thick and extends 180 mm on each side. The plate is assumed to deform in a symmetric manner, so only half of it is discretized, as shown in Figure 3.2.10–1. The half plate is modeled with 10 × 30 CPE4 elements in ABAQUS/Standard and 10 × 30 and 15 × 45 CPE4R elements in ABAQUS/Explicit. The undeformed cylindrical plate has a radius of 90 mm and a thickness of 30 mm, as shown in Figure 3.2.10–1. It is modeled with 10 × 30 CAX4 elements in ABAQUS/Standard and 10 × 30 and 15 × 45 CAX4R elements in ABAQUS/Explicit. In both cases the impactors are assumed to have a radius of 82.5 mm. The bottom nodes of the mesh are fixed, while the outer boundary is free to move.

Uniaxial and hydrostatic compression tests have been conducted on a block of sample polyurethane foam material by Schluppkotten (1999). The yield stress in uniaxial compression is plotted against the axial plastic strain in Figure 3.2.10–2. Insignificant lateral deformation is observed during uniaxial compression. The hydrostatic compression test results show that the initial yield stress in hydrostatic compression, ![]() , is almost the same as that in uniaxial compression,

, is almost the same as that in uniaxial compression, ![]() . The elastic response is approximated by the following constants:

. The elastic response is approximated by the following constants:

The contact between the top exterior surface of the foam plate and the rigid punch is modeled with the *CONTACT PAIR option. Both the cylindrical and hemispherical rigid punches are modeled as analytical rigid surfaces using the *SURFACE option in conjunction with the *RIGID BODY option. Coulomb friction is modeled between the punch and the plate with a friction coefficient of 0.2. The maximum shear traction due to friction is assumed to be ![]() , or 0.115 MPa.

, or 0.115 MPa.

The punch is fully constrained except in the vertical direction, in which motion is prescribed such that the maximum indentation depth is about 90% of the thickness of the plate.

The impactor is displaced statically to indent the foam. To model the large deformations of the foam, the NLGEOM parameter is used on the *STEP option. For nonassociated flow cases UNSYMM=YES is used on the *STEP option. This is important to obtain an acceptable rate of convergence during the equilibrium iterations, since the nonassociated flow plasticity model used for the foam has a nonsymmetric stiffness matrix.

The accuracy of the equilibrium solution within a time increment is controlled by iterating until the out-of-balance forces reduce to a small fraction of an average force magnitude calculated internally by ABAQUS. The rough punch causes an inhomogeneous stress state: stresses are higher in the region of the mesh near the punch. This tends to cause an underestimation of the average force magnitude since the reference force magnitude is averaged over the entire mesh. To avoid an excessive number of iterations, the *CONTROLS, PARAMETERS=FIELD option is used to relax the convergence tolerance.

The plate is indented quasi-statically when the foam is modeled without rate dependence. The SMOOTH parameter on the *AMPLITUDE option is used to specify the displacement of the punch and to promote a quasi-static solution. The plate is indented dynamically when the foam is modeled with rate effects. For this case a ramped velocity profile is prescribed such that the maximum velocity is 5.4 m/sec.

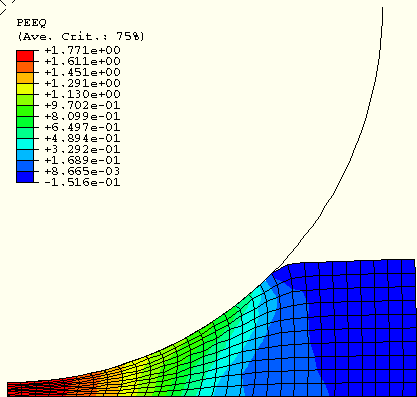

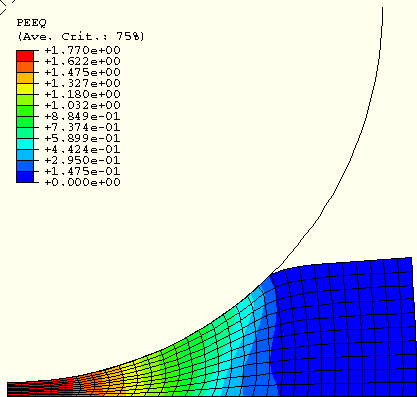

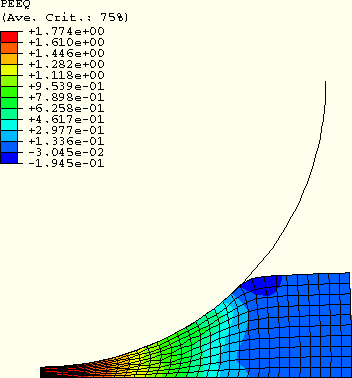

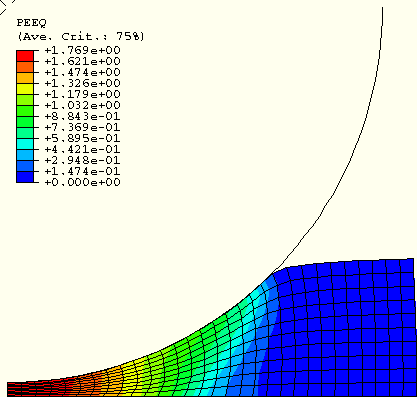

The same response is obtained in ABAQUS/Explicit using the coarse mesh and the fine mesh. The overall load-deflection response of the foam plate is plotted in Figure 3.2.10–3 for indentation with the cylindrical punch and in Figure 3.2.10–4 for indentation with the hemispherical punch. In both cases the simulated load-deflection responses are in good agreement with the experimental results by Schluppkotten (1999). The deformed configuration of the mesh at the end of the loading step (showing actual displacements) and the contour plots of the equivalent plastic strain (for the isotropic hardening foam model in ABAQUS/Explicit) or the volumetric compacting plastic strain (for the volumetric hardening foam model in ABAQUS/Explicit and the crushable foam model in ABAQUS/Standard) are shown in Figure 3.2.10–5 through Figure 3.2.10–10. The figures show that the plastic strain magnitude in the vicinity of the punch approaches 180%.

Rate-independent case with cylindrical impactor and coarse mesh of the plate.

Rate-independent case with hemispherical impactor and coarse mesh of the plate.

Rate-independent case with cylindrical impactor, coarse mesh of the plate, and the isotropic hardening foam model.

Rate-independent case with cylindrical impactor, fine mesh of the plate, and the isotropic hardening foam model.

Rate-dependent case with cylindrical impactor, coarse mesh of the plate, and the isotropic hardening foam model.

Rate-independent case with cylindrical impactor, coarse mesh of the plate, and the volumetric hardening foam model.

Rate-independent case with cylindrical impactor, fine mesh of the plate, and the volumetric hardening foam model.

Rate-dependent case with cylindrical impactor, coarse mesh of the plate, and the volumetric hardening foam model.

Rate-independent case with hemispherical impactor, coarse mesh of the plate, and the isotropic hardening foam model.

Rate-independent case with hemispherical impactor, fine mesh of the plate, and the isotropic hardening foam model.

Rate-dependent case with hemispherical impactor, coarse mesh of the plate, and the isotropic hardening foam model.

Rate-independent case with hemispherical impactor, coarse mesh of the plate, and the volumetric hardening foam model.

Rate-independent case with hemispherical impactor, fine mesh of the plate, and the volumetric hardening foam model.

Rate-dependent case with hemispherical impactor, coarse mesh of the plate, and the volumetric hardening foam model.

Schluppkotten, J., Investigation of the ABAQUS/Crushable Foam Plasticity Model, Internal report of BMW AG, 1999.

Figure 3.2.10–5 Deformed configuration and contours of the equivalent plastic strain for indentation with cylindrical impactor and the isotropic hardening foam model in ABAQUS/Explicit.

Figure 3.2.10–6 Deformed configuration and contours of the volumetric compacting plastic strain for indentation with cylindrical impactor and the volumetric hardening foam model in ABAQUS/Explicit.

Figure 3.2.10–7 Deformed configuration and contours of the equivalent plastic strain for indentation with hemispherical impactor and the isotropic hardening foam model in ABAQUS/Explicit.

Figure 3.2.10–8 Deformed configuration and contours of the volumetric compacting plastic strain for indentation with hemispherical impactor and the volumetric hardening foam model in ABAQUS/Explicit.