ABAQUS/CAE can apply the swept meshing technique to solid regions that can be replicated by sweeping a source side along an edge to the target side. For a three-dimensional solid the sweep path is an edge, but the source and target sides are faces. The cross-section of a swept region must remain constant and planar from the source side to the target side. Figure 17–61 illustrates an extruded swept mesh—ABAQUS/CAE meshes the source side and extrudes that mesh along a straight edge to the target side.

Figure 17–61 The extruded swept meshing technique sweeps the mesh on the source side along a straight edge.

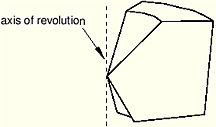

Figure 17–62 illustrates a revolved swept mesh—ABAQUS/CAE meshes the source side and revolves that mesh about the axis of the circular edge to the target side.

Figure 17–62 The revolved swept meshing technique sweeps the mesh on the source side along a circular edge.

If a region is swept meshable, ABAQUS/CAE can generate the swept mesh on a region that has been assigned the Hex, Hex-dominated, or Wedge element shape option. To generate the preliminary two-dimensional mesh on the source side, ABAQUS/CAE uses the free meshing technique with the Quad, Quad-dominated, or Tri element shape option, respectively.

You can choose between the medial axis and advancing front meshing algorithms when you mesh a solid region with hexahedral or hexahedral-dominated elements using the swept meshing technique. (ABAQUS/CAE generates hexahedral and hexahedral-dominated meshes by sweeping the quadrilateral and quadrilateral-dominated elements generated by the two algorithms from the source side to the target side.) For more information, see “What is the difference between the medial axis algorithm and the advancing front algorithm?,” Section 17.7.6, and “Free meshing with quadrilateral and quadrilateral-dominated elements,” Section 17.9.2.

The following limitations apply to three-dimensional swept meshing:

Every side that connects the source side to the target side must contain only a single face without isolated edges or isolated vertices. For example, the model in Figure 17–63 cannot be meshed using the swept meshing technique because one of the connecting sides is partitioned into two faces.

Similarly, Figure 17–64 shows a part that cannot be swept meshed with hexahedral elements because the connecting side contains six rings. To make the part swept meshable, you can create partitions at these rings using the N-sided patch partition tool. The part now consists of seven separate swept cells, and the connecting side of each cell contains only a single face. As a result, the part is now swept meshable.The target side must contain only a single face without isolated edges or isolated vertices. For example, the region on the left in Figure 17–65 can be meshed using the swept meshing technique because all of the isolated edges are on the source side; the region on the right, however, cannot be meshed using this technique because the target side contains two faces.

The cross-section of a swept region must remain constant and planar from the source side to the target side. As a result, a lofted part is not swept meshable. If the source or target face is not planar, you may be able to partition the solid into regions that can be meshed with the structured meshing technique, as shown in Figure 17–66.

A solid part is not swept meshable if the sweep path is comprised of multiple edges. However, the part instance may be swept meshable if you can partition the part into a sequence of sweep paths.

For a revolved region, the profile that was revolved to create the region must not touch the axis of revolution at one or more isolated points, as shown in Figure 17–67.

Figure 17–67 The swept meshing technique cannot mesh a part if an isolated point touches the axis of revolution.

Figure 17–68 ABAQUS/CAE cannot mesh a region with hexahedral elements if one or more edges lie along the axis of revolution.

A fully revolved region that does not touch the axis of revolution is meshable only if all the edges that are associated with the profile being revolved exist. However, the edges that bound the profile must not create a face. Figure 17–70 shows a meshable part instance where all of the edges of the revolved profile exist.

In this example the user sketched the profile, and ABAQUS/CAE revolved the profile to create the part; however, the edges that bound the profile do not form a face. In contrast, Figure 17–71 shows a part instance that is not meshable because some of the edges of the revolved profile are missing.A fully revolved region that touches the axis of revolution is meshable only if all of the edges that are associated with the profile being revolved exist except the edges along the axis of revolution. Figure 17–72 shows a part instance that is meshable because all of the edges of the revolved profile exist except for the edge along the axis of revolution. If the profile included the edge along the axis of revolution, the part instance would not be meshable.