Products: ABAQUS/Explicit ABAQUS/CAE

This section highlights the difficulties that are most commonly encountered when modeling contact interactions with contact pairs in ABAQUS/Explicit. Most of these issues are not relevant when the general contact algorithm is used; refer to “Defining general contact interactions,” Section 21.3.1, for more information on the issues involved with general contact interactions. Recommendations on how to circumvent these problems are presented.

When defining three-dimensional surfaces formed by element faces, avoid defining two surface nodes with the same coordinates. Such a definition can give rise to a seam, or crack, in the surface as shown in Figure 21.4.6–1.

If viewed with the default plotting options in ABAQUS/CAE, this surface will appear to be a valid, continuous surface; however, a node sliding along this surface can fall through this crack and violate the contact conditions. If this were to happen, ABAQUS/Explicit would enforce the contact conditions by applying a large acceleration to the node once overclosure is detected. The large resulting acceleration may create a noisy solution or cause the elements to distort badly.Use the edge display options in the Visualization module of ABAQUS/CAE to identify any unwanted cracks in the surfaces used in the model. The cracks will appear as extra perimeter lines in the interior of the surface. Duplicate nodes can be avoided easily by equivalencing nodes when creating the model in a preprocessor.

Occasionally, surface definitions may not be suitable for modeling the desired contact conditions in a problem. Figure 21.4.6–2 shows a two-dimensional model of a simple connection between two parts.

The surfaces shown in the figure are inadequate for the desired contact conditions that are also shown. At the start of the simulation, ABAQUS/Explicit will detect that some of the nodes on surface 3 are behind surfaces 1 and 2. When the contact conditions are enforced, the motions of the surfaces will likely cause badly distorted elements. One solution to this problem is shown in Figure 21.4.6–3. The surfaces shown in that figure are suitable for the desired contact definition. Other solutions, such as using a pure master-slave contact pair, exist for this problem and may be more suitable, depending on the details of the intended simulation.

Several problems are caused by surfaces created on very coarse meshes.

When a coarsely discretized surface is used as the slave surface in a pure master-slave contact pair with hard surface behavior, an inaccurate solution may be produced as a result of the gross penetration of the master surface into the slave surface. This situation is shown in Figure 21.4.6–4. This problem can be minimized if the contact pair can be switched to a balanced master-slave contact pair. However, some contact pairs in ABAQUS/Explicit must always use a pure master-slave formulation. In these cases the only solution to gross penetration is to refine the slave surface.

For rigid surfaces formed by element faces, inaccurate results may be obtained if too few elements are used to represent a curved geometry. When a very coarse mesh is used on a curved geometry, it is possible for slave nodes to get “snagged” on the sharp vertices.

In general, using a reasonable number of element faces to represent a curved surface will not increase the computational time of the simulations. However, a large number of element faces can significantly increase the memory that ABAQUS/Explicit will need for the simulation. When a specific curved surface geometry can be modeled, using an analytical rigid surface may provide a more accurate geometric description while minimizing computational expense; see “Defining analytical rigid surfaces,” Section 2.3.4.

Calculating the correct contact conditions along a surface that is highly warped is very difficult, especially when the relative velocity of the contacting surfaces is very large. By default, ABAQUS/Explicit monitors the orientation of every deformable master surface formed by element faces every 20 increments to check that the surface is not highly warped; rigid faceted surfaces are checked for large warping only at the beginning of a step. If a surface becomes highly warped, a warning message is issued in the status (.sta) file, and a more accurate algorithm is used to calculate each slave node's nearest point on the warped master surface. The alternate algorithm provides a more accurate solution but uses slightly more computational time.

By default, ABAQUS/Explicit considers a surface to be highly warped when the angle between surface normals at the nodes of a facet varies by more than 20°. The maximum variation of the surface normal over a facet is called the out-of-plane warping angle. You can change the default value of the out-of-plane warping angle cutoff from step to step for any contact pair in the model.

| Input File Usage: | *CONTACT CONTROLS, CPSET=contact_pair_set_name, WARP CUT OFF=angle |

| ABAQUS/CAE Usage: | Interaction module: |

Create Contact Controls: Name: contact_controls_name, ABAQUS/Explicit contact controls: Angle criteria for highly warped facet (degrees): angle Interaction editor: Contact controls: contact_controls_name |

You can specify the frequency, in increments, at which ABAQUS/Explicit checks for warped surfaces for any contact pair in the model. The frequency can be changed from step to step. Checking for warped surfaces more frequently (the default is every 20 increments) will cause a slight increase in computational time for the analysis.

| Input File Usage: | *CONTACT CONTROLS, CPSET=contact_pair_set_name, WARP CHECK PERIOD=n |

| ABAQUS/CAE Usage: | Interaction module: |

Create Contact Controls: Name: contact_controls_name, ABAQUS/Explicit contact controls: Warp check increment: n Interaction editor: Contact controls: contact_controls_name |

By default, ABAQUS/Explicit writes a warning message in the status (.sta) file the first time that it detects that a surface is highly warped. The message is brief; it states only which surface has a highly warped facet. If additional facets on this surface become highly warped later in the analysis, no additional warning messages are issued.

You can request more detailed diagnostic warning messages, if desired. In this case the message file will contain a warning every time a warped facet is found on a particular surface. The warnings will give the parent element associated with the warped facet (the parent element is the element whose face forms the facet) and the warping angle of the facet.

The computation time and the size of the message file can increase significantly if detailed warnings are requested. You can switch back to the summary warnings in subsequent steps or suppress the warped surface warnings entirely.

If the analysis terminates with a fatal error, the preselected output variables will be added automatically to the output database as field data for the last increment.

| Input File Usage: | Use the following option to request detailed diagnostic warning output for warped surfaces: |

*DIAGNOSTICS, WARPED SURFACE=DETAIL Use the following option to request the default summary diagnostic output for warped surfaces: *DIAGNOSTICS, WARPED SURFACE=SUMMARY Use the following option to suppress diagnostic warning output for warped surfaces entirely: *DIAGNOSTICS, WARPED SURFACE=OFF |

| ABAQUS/CAE Usage: | Diagnostic output requests for warped surfaces are not supported in ABAQUS/CAE. |

If boundary constraints are applied to contact nodes on both surfaces of a contact pair in the direction that the contact constraints are active, the boundary constraints may override the contact constraints. For kinematic contact, contact force related quantities will be output as the force necessary to resolve the contact constraint in a single increment, causing misleading results for these output quantities if the boundary constraints violate the contact constraints. Contact force output for penalty contact does not show this behavior since the contact force is proportional only to the current penetration and does not depend on the time increment. Boundary constraints are not affected by contact constraints.

Using a multi-point constraint (MPC) with a node on a surface that is part of an active kinematic contact pair can generate conflicting kinematic constraints in the model. ABAQUS/Explicit will not prevent you from using multi-point constraints on the nodes forming a surface. If the contact constraints and the constraints formed by the MPC are orthogonal, there will be no problems with the simulations. If they are not orthogonal, the solution may be noisy as ABAQUS/Explicit tries to satisfy the conflicting constraints. Since within each increment kinematic contact constraints are applied after MPCs are applied, the MPCs on kinematic contact surfaces may be slightly out of compliance.

In the case of an interaction between an MPC and penalty contact, the MPC is strictly enforced and any noncompliance in the contact pair will be resisted by penalty forces.

When a shell or membrane is pinched between two master surfaces using two kinematic contact pairs with hard contact behavior, one of the contact constraints will not be enforced exactly. In a quasi-static analysis it may be observed that the pinched slave node will oscillate about an “equilibrium” penetration depth with a decay rate that depends on the time increment and the ratio of the mass of the pinched node and the mass of the master surfaces. Decreasing the time increment size will increase the decay rate (quasi-static equilibrium will be reached more quickly). Reducing the mass of the nodes on the master surfaces (or increasing the mass of the pinched nodes) will also increase the decay rate, although a high ratio of slave mass to master mass can also lead to numerical difficulties for kinematic contact, as discussed below in “Large mass mismatch between contact surfaces.” Applying the loads to the model gradually will reduce the amplitude of the oscillation. In most analyses it is not desirable to alter the time increment or nodal masses arbitrarily, so the decay rate of the oscillation will be fixed. Either the loading rate can be modified or a softened contact model with contact damping can be used to control this oscillatory behavior.

The quasi-static equilibrium penetration magnitude, ![]() , is approximately given by

, is approximately given by

![]()

If one kinematic contact pair and one penalty contact pair are used to model the same type of pinching problem, the kinematic constraint is enforced exactly and the static value of the penetration in the penalty contact pair is somewhat larger than that which occurs when kinematic contact is used for both contact pairs (assuming that the penalty stiffness is set such that the analysis is numerically stable for the time increment being used).

If a node that is not attached to shell or membrane elements acts as a slave node in two or more simultaneous, kinematic contact constraints, the resulting contact corrections may be erroneous, possibly causing the analysis to abort with excessive element distortion. By “not attached to shell or membrane elements” we are referring to nodes attached to solid elements or point masses, for example. The majority of solid nodes typically are not involved in simultaneous contacts, but there are common exceptions where three or more bodies meet at corners. This limitation can be avoided by using penalty contact. For example, if a solid surface acts as a slave in two contact pairs and there is a possibility of simultaneous contacts for individual slave nodes, penalty enforcement of contact should be specified for one or both of the contact pairs.

Redundant contact constraints are caused by overlapping or adjoining surfaces. For example, if contact is specified between a single surface and multiple overlapping surfaces, the contact constraints associated with the common nodes of the overlapping surfaces are redundant. Degenerate contact constraints occur if the slave surface and master surface of the same contact pair contain common nodes (a contact constraint cannot be formed between a node and itself).

If redundant kinematic contact constraints are specified, ABAQUS/Explicit will consolidate the constraints if both contact pairs use pure master-slave contact, the slave surfaces do not share facets, and the surface interaction and contact pair set names are identical. If the contact pair definitions differ, the analysis will terminate with an error, and one of the redundant constraints must be removed from the model definition to continue the analysis.

Redundant penalty contact constraints may cause excessive initial overclosure adjustments, creating gaps in the place of initial overclosures. To correct this behavior, one of the constraints must be removed from the model definition.

Redundant contact constraints involving both a penalty contact pair and a kinematic contact pair cause inefficiencies in the analysis. The kinematic contact constraints will override the penalty contact constraints, but the penalty contact constraints will still be considered in the automatic time increment estimate.

If the surfaces in a two-surface contact pair contain common nodes, the contact constraint for each shared node cannot be generated. This is the equivalent of defining self-contact between the shared nodes and each surface. However, the two-surface contact logic (unlike the specialized self-contact logic) would erroneously detect contact between each shared node and itself. When this condition occurs, ABAQUS/Explicit redefines the slave surfaces so that the shared nodes will not act as slave nodes in the contact pair. However, the shared nodes will still be used in the definition of a master surface in the contact pair.

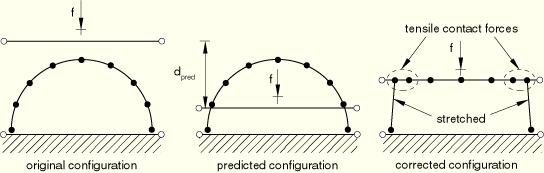

Often very little mass is assigned to rigid bodies in quasi-static simulations because the mass has little influence on the physical problem. However, specifying a small rigid body mass can adversely affect the kinematic contact enforcement method. A force applied to a rigid body with very little mass can cause a large predicted displacement of the rigid body within an increment prior to the enforcement of contact constraints, so significant penetration may be present in the “predicted” configuration for kinematic contact, as shown in Figure 21.4.6–5.

Figure 21.4.6–5 Undesirable numerical behavior of contact algorithm resulting from small rigid body mass.

Similar undesirable numerical behavior can occur for deformable-to-deformable contact if the nodal masses of the master nodes are orders of magnitude less than those of the slave nodes. This problem can often be avoided in such cases by using the pure master-slave algorithm with the master surface containing the more massive nodes.

Some contact noise may occur with hard contact models because of limited computer precision. This noise is rarely significant in an analysis, but it may be noticeable at the beginning of an analysis if initial displacements are used to make the mesh comply with contact constraints. For example, if an adjustment of ![]() is made for an initial overclosure, a penetration of up to

is made for an initial overclosure, a penetration of up to ![]() may still exist in the first increment, where

may still exist in the first increment, where ![]() is the “machine epsilon” of the computer. The machine epsilon of a given computer is defined as the smallest positive number that can be added to 1 with the computed result being greater than 1; on most systems

is the “machine epsilon” of the computer. The machine epsilon of a given computer is defined as the smallest positive number that can be added to 1 with the computed result being greater than 1; on most systems ![]() is approximately 6E–8 for single precision and 1E–16 for double precision. With the kinematic contact algorithm you can attribute initial accelerations of up to

is approximately 6E–8 for single precision and 1E–16 for double precision. With the kinematic contact algorithm you can attribute initial accelerations of up to ![]() to limited machine precision, where

to limited machine precision, where ![]() is the time increment. For a single precision analysis in which

is the time increment. For a single precision analysis in which ![]() =1E–6 sec, initial accelerations of up to 6E4 sec–2

=1E–6 sec, initial accelerations of up to 6E4 sec–2![]() can be attributed to limited machine precision. These accelerations are typically insignificant. They can be reduced by conducting the analysis with double precision or by specifying the nodal coordinates to be more compliant with contact constraints.

can be attributed to limited machine precision. These accelerations are typically insignificant. They can be reduced by conducting the analysis with double precision or by specifying the nodal coordinates to be more compliant with contact constraints.

When a pure master-slave contact constraint with finite sliding is defined near a symmetry plane in the master surface, the corner slave node (node ![]() in Figure 21.4.6–6) can, under some circumstances, slide freely along the symmetry plane without experiencing contact. If the master surface wraps around the corner (node 1), the slave node

in Figure 21.4.6–6) can, under some circumstances, slide freely along the symmetry plane without experiencing contact. If the master surface wraps around the corner (node 1), the slave node ![]() may “track” on the master segment (1–6) on the symmetry plane, rather than on master segment (1–2). The result may be an inaccurate representation of the contact constraint as shown by the shaded area.

may “track” on the master segment (1–6) on the symmetry plane, rather than on master segment (1–2). The result may be an inaccurate representation of the contact constraint as shown by the shaded area.

If the master surface does not wrap around the corner (node 1 in Figure 21.4.6–7), the contact logic may give different results depending on how the symmetry boundary conditions have been defined for the master node 1 on the symmetry plane. If the symmetry boundary conditions on the master node are specified using boundary “type” format (i.e., XSYMM, YSYMM, or ZSYMM—see “Boundary conditions,” Section 19.3.1), the master surface is effectively extended beyond the symmetry plane (Figure 21.4.6–7); thus, the slave node ![]() will be detected as a “penetrated” node (penetrated by distance

will be detected as a “penetrated” node (penetrated by distance ![]() ). Therefore, a correcting force would be applied on slave node

). Therefore, a correcting force would be applied on slave node ![]() to push it below the master surface.

to push it below the master surface.

If the symmetry boundary conditions on the master node 1 are specified using “direct” format (i.e., specifying the components of translations and rotations that are fixed), the master surface is not extended beyond the symmetry plane (Figure 21.4.6–8) and it is possible that contact will not be enforced correctly.

To ensure proper enforcement of finite-sliding contact near symmetry planes, use balanced master-slave contact or use pure master-slave contact without extending the surface onto the symmetry plane and use symmetry “type” boundary conditions on the perimeter of the master surface nodes as discussed above. Special consideration of small-sliding contact near a symmetry plane is discussed in “Contact formulation for ABAQUS/Explicit contact pairs,” Section 21.4.4.

You can define initial clearances and contact directions precisely for the nodes on the slave surface (see “Specifying initial clearance values precisely” in “Adjusting initial surface positions and specifying initial clearances in ABAQUS/Explicit contact pairs,” Section 21.4.5). The initial clearance or overclosure value calculated at every slave node based on the coordinates of the slave node and the master surface is overwritten by the value that you specify; the coordinates of the slave nodes are not altered. This technique permits exact specification of initial clearances (and, possibly, contact directions) when they would not be computed accurately enough from the nodal coordinates; for example, if the initial clearance is very small compared to the coordinate values. It can be used only in small-sliding contact analyses (“Contact formulation for ABAQUS/Explicit contact pairs,” Section 21.4.4).

When the balanced-master slave contact algorithm is invoked for the contact pair, the initial clearance values can be defined on one or both of the surfaces. Initial clearances defined on contact surfaces that act only as master surfaces will be ignored.

ABAQUS/Explicit does not adjust the coordinates of the slave surface when precise initial clearances are specified for small-sliding contact pairs (see “Adjusting initial surface positions and specifying initial clearances in ABAQUS/Explicit contact pairs,” Section 21.4.5). Therefore, the specified clearances cannot be seen in a postprocessor such as the Visualization module of ABAQUS/CAE. Thus, depending on the initial geometry of the surfaces and the magnitude of the clearances or overclosures, the surfaces may appear open or closed in the postprocessor when they are actually just in contact.