Products: ABAQUS/Standard ABAQUS/Explicit ABAQUS/CAE

A surface-based tie constraint:

ties two surfaces together for the duration of a simulation;

can be used only with surface-based constraint definitions;

can be used in mechanical, coupled temperature-displacement, acoustic pressure, coupled acoustic pressure-displacement, coupled pore pressure–displacement, coupled thermal-electrical, or heat transfer simulations;

can also be used to create a constraint on a surface so that it follows the motion of a three-dimensional beam;

is useful for mesh refinement purposes, especially for three-dimensional problems;

allows for rapid transitions in mesh density within the model;

constrains each of the nodes on the slave surface to have the same motion and the same value of temperature, pore pressure, acoustic pressure, or electrical potential as the point on the master surface to which it is closest;

will take the initial thickness and offset of shell elements underlying the surface into account by default; and

eliminates the degrees of freedom of the slave surface nodes that are constrained, where possible.

A surface-based tie constraint can be used to make the translational and rotational motion as well as all other active degrees of freedom equal for a pair of surfaces. By default, as discussed below, nodes are tied only where the surfaces are close to one another. One surface in the constraint is designated to be the slave surface; the other surface is the master surface. A name must be assigned to this constraint and may be used in postprocessing with ABAQUS/CAE.

| Input File Usage: | *TIE, NAME=name slave_surface_name, master_surface_name |

| ABAQUS/CAE Usage: | Interaction module: Create Constraint: Tie |

Either element-based or node-based surfaces can be used as the slave surface. Any surface type (element-based, node-based, or analytical) can be used as the master surface. Element-based surfaces can be single-sided, double-sided, or edge-based. When the master surface is node-based, the slave node is constrained to the closest master node.

| Input File Usage: | Use the *SURFACE option to define the slave and master surfaces used in the constraint (see “Surfaces: overview,” Section 2.3.1): |

*SURFACE, NAME=slave_surface_name *SURFACE, NAME=master_surface_name |

| ABAQUS/CAE Usage: | In ABAQUS/CAE you can select one or more faces directly in the viewport when you are prompted to select a surface. In addition, you can define surfaces as collections of faces and edges using the Surface toolset. |

By default, ABAQUS uses a position tolerance criterion to determine the constrained nodes based on the distance between the slave nodes and the master surface. Alternatively, you can specify a node set containing the slave nodes to be constrained regardless of their distance to the master surface.

The default position tolerance criterion ensures that nodes are tied only where the slave and master surfaces are close to one another in the initial configuration. For example, consider the case shown in Figure 20.3.1–1. Surfaces Comp1_surf and Comp2_surf are defined to cover all exposed faces of Component 1 and Component 2, respectively. These two surfaces can be used as the slave and master surfaces in a tie constraint to tie the two components in the desired region, because only the nodes at the initial interface between the two surfaces are tied.

The default value of the position tolerance, ![]() , typically results in desired tie constraints with little effort. Details regarding the calculation of distances between surfaces and default values of the position tolerances are provided below. You can modify the position tolerance if desired.

, typically results in desired tie constraints with little effort. Details regarding the calculation of distances between surfaces and default values of the position tolerances are provided below. You can modify the position tolerance if desired.

| Input File Usage: | Use the following option to use the default position tolerance: |

*TIE Use the following option to specify a position tolerance: *TIE, POSITION TOLERANCE=distance |

| ABAQUS/CAE Usage: | Interaction module: Create Constraint: Tie: Position Tolerance: Specify distance |

The following factors influence the calculation of the distance between surfaces for a particular slave node:

Shell thickness. By default, calculations of distances between surfaces account for shell thickness and offset effects for element-based slave or master surfaces: the distance is measured from the actual top or bottom side of the surface, whichever is closer to the other surface. Alternatively, you can specify that surface thicknesses and offsets should be ignored, which also has implications for nodal position adjustments for resolving initial gaps (discussed later).

| Input File Usage: | Use the following option to ignore surface thicknesses and offsets in the distance calculations: |

*TIE, NO THICKNESS |

| ABAQUS/CAE Usage: | Interaction module: Create Constraint: Tie: Exclude shell element thickness |

Whether the surface-to-surface or node-to-surface constraint formulation (discussed below) is used. If a position tolerance is in effect, a constraint is generated at a slave node for either formulation if the distance between the surfaces, as calculated at the slave node, does not exceed ![]() . Additional slave nodes may be tied if the surface-to-surface constraint formulation is used along with an element-based slave surface and a master surface that is not node-based, because the following addendum to the position tolerance criterion applies in such cases: if the distance between the surfaces is within

. Additional slave nodes may be tied if the surface-to-surface constraint formulation is used along with an element-based slave surface and a master surface that is not node-based, because the following addendum to the position tolerance criterion applies in such cases: if the distance between the surfaces is within ![]() over a significant portion of a slave face (or segment in two dimensions) that forms an angle of less than 30° with the master surface, all slave nodes attached to such a face (or segment) are considered to satisfy the position tolerance.

over a significant portion of a slave face (or segment in two dimensions) that forms an angle of less than 30° with the master surface, all slave nodes attached to such a face (or segment) are considered to satisfy the position tolerance.

The types of surfaces involved (element-based, node-based, or analytical).

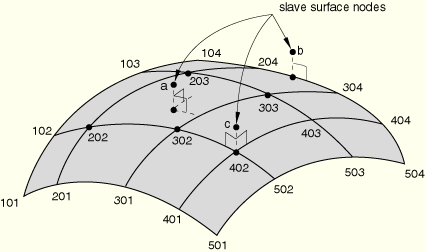

The default position tolerance for element-based master surfaces is 5% of the typical element size in the master surface. When using an element-based master surface, the distance between surfaces for a particular point on a slave surface is based on the closest point on the master surface (which may be on the edge of the master surface or within a facet). Figure 20.3.1–2 shows an example with no thickness: nodes 2–14 satisfy the position tolerance criterion for the node-to-surface and surface-to-surface constraint formulations. Significant portions of the end slave segments (that is, the segment connecting nodes 1 and 2 and the segment connecting nodes 14 and 15) are within the position tolerance shown, so nodes 1 and 15 would also satisfy the position tolerance criterion for the surface-to-surface constraint formulation except for the fact that the angle between the slave and master surfaces is slightly greater than 30° at those locations.

The default position tolerance for a node-based master surface is based on the average distance between nodes in the master surface. The surface-to-surface constraint formulation reverts to the node-to-surface constraint formulation for a node-based master surface. The distance between the surfaces for a particular slave node is based on the closest master node. For mismatched meshes across a tied interface, the distance between slave and master nodes can be much larger than the “normal” distance between the surfaces, which can lead to confusion when using a position tolerance criterion with a node-based master surface. Figure 20.3.1–3 shows how the tolerance region is defined around a node-based master surface.

The default position tolerance for analytical rigid master surfaces is 5% of the typical element size in the slave surface. When using an analytical rigid master surface, the distance between surfaces for a particular point on the slave surface is based on the closest point on the master surface.

This method allows you direct control over which slave nodes are tied.

| Input File Usage: | *TIE, TIED NSET=node_set_label |

| ABAQUS/CAE Usage: | Use one of the following options: |

Interaction module: Create Constraint: Tie: select the master surface: choose Node Region as the slave type: select the slave nodes Create Constraint: Tie: select the master surface: choose Surface as the slave type: select the slave surface |

ABAQUS does not constrain slave nodes to the master surface unless they are included in the tied node set or within the tolerance distance from the master surface at the start of the analysis, as discussed above. Any slave nodes not satisfying these criteria will remain unconstrained for the duration of the simulation; they will never interact with the master surface as part of the tie constraint. In mechanical simulations an unconstrained slave node can penetrate the master surface freely unless contact is defined between the slave node and master surface. The general contact algorithm in ABAQUS/Explicit will generate contact exclusions automatically for slave node–master surface combinations corresponding to constrained nodes of tie constraint pairs, but no such contact exclusions are generated for nodes outside the position tolerance of the constraints. In a thermal, acoustic, electrical, or pore pressure simulation an unconstrained slave node will not exchange heat, fluid pressure, electrical current, or pore fluid pressure with the master surface.

For each tie constraint pair, ABAQUS creates a node set comprising slave nodes that will be tied and a node set comprising slave nodes that will be left unconstrained. These node sets are available for display during postprocessing in ABAQUS/CAE, where they are listed as internal node sets.

In addition, ABAQUS prints a table in the data (.dat) file listing each slave node and the master surface nodes to which it will be tied if model definition data are requested (see “Controlling the amount of analysis input file processor information written to the data file” in “Output,” Section 4.1.1). If a constraint cannot be formed for a given slave node, ABAQUS/Standard will issue a warning message in the data file.

When creating a model with surface-based tie constraints, it is important to use the information provided by ABAQUS to identify any unconstrained nodes and to make any necessary modifications to the model to constrain them.

By default, ABAQUS will constrain the rotational degrees of freedom when they exist on both slave and master surfaces (see Figure 20.3.1–4).

You can specify that the rotational degrees of freedom should not be tied.| Input File Usage: | *TIE, NO ROTATION |

| ABAQUS/CAE Usage: | Interaction module: Create Constraint: Tie: toggle off Tie rotational DOFs if applicable |

You can enforce proper constraints on the faces bounding a repetitive sector of a cyclic symmetric structure (see “Analysis of models that exhibit cyclic symmetry,” Section 7.8.3). This makes it possible to define a single sector of the cyclic symmetry model together with its axis of cyclic symmetry to define the behavior of the 360° model. Cyclic symmetry models can be used within the following procedures: static; quasi-static; eigenfrequency extraction, based on the Lanczos solver technique; steady-state dynamics, based on modal superposition; and heat transfer. If an eigenfrequency extraction is performed on a cyclic symmetric model, the nodes involved in the cyclic symmetry constraint cannot be used in any other constraint (e.g., multi-point constraints, equations, rigid bodies, couplings, or kinematic couplings).

| Input File Usage: | *TIE, CYCLIC SYMMETRY |

| This parameter can be used only with the *CYCLIC SYMMETRY MODEL option. |

| ABAQUS/CAE Usage: | Cyclic symmetry is not supported in ABAQUS/CAE. |

ABAQUS uses the criteria discussed above to determine which slave nodes will be tied to the master surface. ABAQUS then forms constraints between these slave nodes and the nodes on the master surface. A key aspect in forming the constraint for each slave node is determining the tie coefficients. These coefficients are used to interpolate quantities from the master nodes to the tie point. ABAQUS can use one of two approaches to generate the coefficients: the “surface-to-surface” approach or the “node-to-surface” approach.

If an analysis carried out with ABAQUS/Standard is imported into ABAQUS/Explicit or vice-versa, the tie constraints are not imported and must be redefined. If the imported analysis is essentially a continuation of the original analysis, it is important that the tie constraints are as similar as possible. Hence, you should make sure that the same constraint type is used. If the default approach was used in the original ABAQUS/Standard analysis, the surface-to-surface approach should be specified in the ABAQUS/Explicit analysis. Similarly, if the default approach was used in the original ABAQUS/Explicit analysis, the node-to-surface approach should be specified in the ABAQUS/Standard analysis.

The true “surface-to-surface” approach (which is used by default with one exception in ABAQUS/Standard and is optional in ABAQUS/Explicit) optimizes the stress accuracy for a given surface pairing. The improved stress accuracy with the surface-to-surface approach is realized only if neither surface of the tie pairing is node-based. The surface-to-surface approach can result in increased computational cost during preprocessing if the surfaces being tied are large. The surface-to-surface approach generally involves more master nodes per constraint than the node-to-surface approach, which tends to increase the solver bandwidth in ABAQUS/Standard and, therefore, can increase solution cost. In most applications the extra cost is fairly small, but the cost can become significant in some cases. The following factors (especially in combination) can lead to the surface-to-surface approach being quite costly:

A large fraction of tied nodes (degrees of freedom) in the model

The master surface being more refined than the slave surface

Multiple layers of tied shells, such that the master surface of one tie constraint acts as the slave surface of another tie constraint

The surface-to-surface method for establishing the tie coefficients involves a more complex algorithm than the node-to-node method; it generally uses more master nodes per constraint.

| Input File Usage: | *TIE, TYPE=SURFACE TO SURFACE |

| ABAQUS/CAE Usage: | Interaction module: Create Constraint: Tie: Constraint enforcement method: Surface to surface |

The traditional “node-to-surface” approach (which is used by default in ABAQUS/Explicit and is optional in ABAQUS/Standard) sets the coefficients equal to the interpolation functions at the point where the slave node projects onto the master surface. This approach is somewhat more efficient and robust for complex surfaces.

For the node-to-surface method of establishing the tie coefficients with an element-based master surface, the point on the surface closest to each slave node is calculated and used to determine the master nodes that are going to form the constraint (see Figure 20.3.1–5). For example, nodes 202, 203, 302, and 303 are used to constrain node ![]() ; nodes 204 and 304 are used to constrain node

; nodes 204 and 304 are used to constrain node ![]() ; and node 402 is used to constrain node

; and node 402 is used to constrain node ![]() .

.

Figure 20.3.1–5 Searching for the points on an element-based master surface that are closest to nodes ![]() ,

, ![]() , and

, and ![]() .

.

| Input File Usage: | *TIE, TYPE=NODE TO SURFACE |

| ABAQUS/CAE Usage: | Interaction module: Create Constraint: Tie: Constraint enforcement method: Node to surface |

The choice of slave and master surfaces can have a significant effect on the accuracy of the solution, in particular if the “node-to-surface” approach is used. The effect is much less (and the accuracy generally better) for the “surface-to-surface” approach. In either case, if both surfaces in a constraint pair are deformable surfaces, the master surface should be chosen as the surface with the coarser mesh for best accuracy.

In ABAQUS/Standard a rigid surface cannot act as a slave surface in a tie constraint. To comply with this rule, the capability to automatically resolve overconstraints in ABAQUS/Standard (see “Overconstraint checks,” Section 20.6.1) will modify tie constraint definitions in the following cases:

Tie constraints between two surfaces of the same rigid body are removed.

Tie constraints between two surfaces of two rigid bodies are replaced by a BEAM-type connector between the respective rigid body reference nodes.

Tie constraints specified with a purely rigid slave surface and a purely deformable master surface are modified to reverse the master and slave assignments unless this is not possible due to other modeling restrictions (in which case an error message is issued).

In acoustic, structural-acoustic, and elastic wave propagation problems care should be exercised when tying meshes of highly dissimilar refinement. If two media have different wave speeds, the optimal meshes for each of the media will have different characteristic element lengths: the faster medium will have larger elements. If surfaces of these meshes are used in a tie constraint, the surface of the finer mesh (of the slower medium) should be designated as the slave. Nevertheless, in the region near the tied surfaces, the physical wave phenomena in both fast and slow media will typically have length scales characteristic of the slower medium; that is, of the shortest length scale in the physical problem. Therefore, if these phenomena are important, the mesh of the faster medium should be refined to the scale of the slower medium in the vicinity of the contact region.

By default, with the exceptions mentioned below, ABAQUS will automatically reposition the slave nodes to be tied in the initial configuration without causing strain to resolve gaps such that the surfaces are just touching, accounting for any shell thickness (unless you have specified that thickness should not be accounted for, as discussed above in the context of the position tolerance criterion) but not accounting for beam or membrane thickness. One exception is that no adjustments are made where tied surfaces are closer together than the combined half-shell thickness. All adjustments are performed such that the slave and master surfaces are never pushed apart; that is, the reference surfaces will only become closer as a result of the adjustments.

It is recommended that you allow the automatic adjustments to occur, especially if neither surface has rotations; in this case a constant offset vector is used, so incorrect behavior of the constraint under rigid body rotation can occur when slave nodes are not lying exactly on the master surface. Adjustments are not made if the slave surface belongs to a substructure or when either the slave or master surface is a beam element-based surface; in the latter cases you should locate the beam element nodes with the desired offset from the other surface.

| Input File Usage: | *TIE, ADJUST=YES or NO |

| ABAQUS/CAE Usage: | Interaction module: Create Constraint: Tie: toggle Adjust slave node initial position |

A slave node is considered for adjustment if both of the following conditions are met:

The slave node satisfies whatever criterion is in effect for generating a constraint (either because it satisfies the position tolerance criterion or belongs to the specified node set of constrained slave nodes, as previously discussed).

The slave node is more than the combined half-shell thickness of the master and the slave surface away from its projection point on the master reference surface.

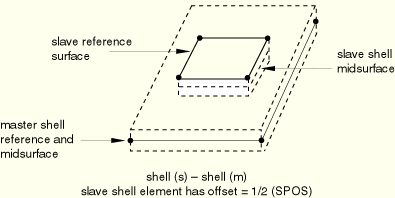

Figure 20.3.1–6 Adjusted slave node position for two shell element-based surfaces tied together. The slave shell element has an offset of 0.5.

Adjustments are made only for slave nodes that are included in the user-specified tied node set or that meet the tolerance criteria described above.

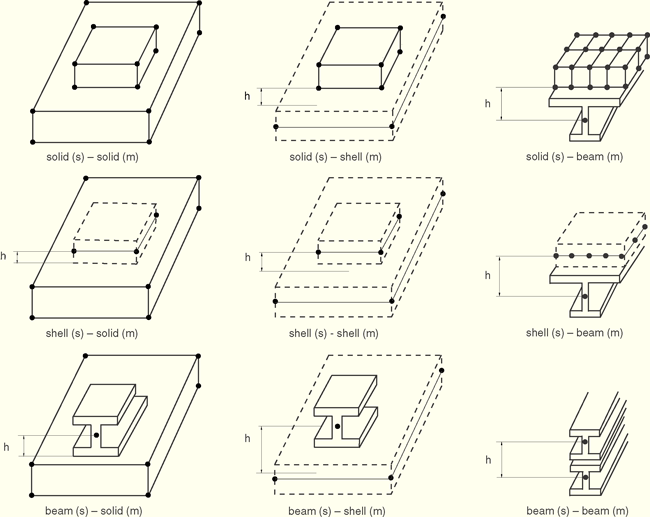

ABAQUS allows a gap to exist between tied surfaces. Such gaps may exist if you prevent nodal adjustments for tied surfaces. A gap between the reference surfaces may remain due to the presence of shell thickness even if nodal adjustments are performed. Figure 20.3.1–7 shows some cases where an offset between the reference surfaces may be desirable for tied surface pairs to account for shell or beam thickness. Rigid body motion is properly accounted for when the nodes are separated by a finite distance when at least one of the surfaces is based on shell or beam elements; when the master surface is an analytical rigid surface; or, in the case of node-based surfaces, when the nodes on at least one surface have active rotational degrees of freedom.

The nature of the constraint on translational motion between surfaces in ABAQUS depends on whether there is an offset between the surfaces and on which surfaces have rotational degrees of freedom, as discussed below.

Figure 20.3.1–7 Tie constraints being applied between surfaces based on various element types (h = offset between slave and master surfaces).

If neither surface has rotational degrees of freedom, the global translational degrees of freedom of the slave node and the closest point on the master surface are constrained to be the same. When an offset exists, ABAQUS will enforce the constraint through the fixed offset like a PIN-type MPC when the nodes in the MPC are not coincident. Because the fixed offset does not rotate, the surface-based constraint will not represent rigid body rotation correctly. The constraint will represent rigid body motion correctly when the offset is zero. This behavior can be ensured by specifying that all tied slave nodes should be moved onto the master surface.

If the slave surface has rotational degrees of freedom and the master surface does not, the translational motion is constrained at the closest point on the master reference surface. When the reference surfaces are offset, a moment will be applied to each slave node based on the constraint force times the offset distance. Similarly, if the master surface has rotational degrees of freedom and the slave surface does not, the translational motion is constrained at each slave node and a moment will be applied to the relevant nodes on the master surface if an offset exists. In either case the surface-based constraint will behave correctly under rigid body rotation regardless of the amount of offset.

If both surfaces have rotational degrees of freedom, are not offset, and the rotations are tied, each slave node is constrained to the master surface like a TIE-type MPC. If an offset exists between the surfaces, the constraint acts like a BEAM-type MPC between the slave node and the closest point on the master reference surface.

If the rotations are not tied, ABAQUS allows you to choose the location of the translational constraint. It can be enforced at the master reference surface, the slave reference surface, or anywhere in between. The location of the translational constraint enforcement for surfaces where the rotations are not tied will affect the distribution of moment to each of the surfaces. The most physically reasonable choice is to locate the constraint at the point where the actual top or bottom sides of each surface meet. The constraint then models a perfect adhesive between the surfaces, which transfers shear stress to each surface. ABAQUS will choose the location of the translational constraint as follows:

If the master surface is shell element-based, the translational constraint is enforced on the top or bottom side of the master surface.

If the slave surface is shell element-based and the master surface is not, the translational constraint is enforced at the top or bottom side of the slave surface.

Otherwise, the translational constraint is enforced at the master reference surface.

To override these default locations, you can specify a constraint ratio for the tie constraint equal to the fractional distance between the master reference surface and the slave node at which the translational constraint should act. Figure 20.3.1–8 shows an example of the use of a constraint ratio to prescribe the location of the translational constraint between two shell surfaces that are tied together with no rotational constraints. The distance between the master reference surface and the slave reference surface is ![]() . The prescribed constraint ratio,

. The prescribed constraint ratio, ![]() , is then used to locate the translational constraint at a distance

, is then used to locate the translational constraint at a distance ![]() from the master reference surface. All distances are measured along the vector between the slave node and its projection point onto the master reference surface. The constraint behavior is then similar to that of two rigid beams pinned together, as shown.

from the master reference surface. All distances are measured along the vector between the slave node and its projection point onto the master reference surface. The constraint behavior is then similar to that of two rigid beams pinned together, as shown.

| Input File Usage: | *TIE, CONSTRAINT RATIO=value |

| ABAQUS/CAE Usage: | Interaction module: Create Constraint: Tie: Constraint ratio |

The master surface for a tie constraint can be based on three-dimensional beam elements. For this case each slave node is projected onto the line formed by the nodes of the beam elements in the undeformed configuration to find the projection point. During the subsequent analysis the motion of each slave node is rigidly constrained to the motion (translation and rotation) of its projection point; i.e., each slave node and its projection point are connected by a rigid beam. Constraining other elements to a beam element-based master surface allows modeling of interactions between the surface of a (complex) beam section and its surroundings, without having to model the beam with continuum and/or shell elements. This feature can be particularly useful for modeling acoustic-structural interactions.

Note: ABAQUS/CAE currently does not support master surfaces based on beam elements.

The surface-based tie constraint capability can be used in models where the nodal degrees of freedom on both the slave and master surfaces include electrical potential, pore pressure, acoustic pressure, and/or temperature. Except for the type of nodal degree of freedom being constrained, ABAQUS uses exactly the same formulation for the tie constraint in nonmechanical simulations as it does for mechanical simulations. In general, degrees of freedom common to both surfaces are tied, and any other degrees of freedom are unconstrained.

The case of structural-acoustic constraints is the exception to this rule. Here, appropriate relations between the acoustic pressure on the fluid surface and displacements on the solid surface are formed internally (see “Acoustic, shock, and coupled acoustic-structural analysis,” Section 6.9.1). The displacements and/or pressure degrees of freedom on the surfaces are the only ones affected; rotations are ignored by the tie constraint in this case.

The internally computed structural-acoustic coupling conditions use the surface areas of the slave surface elements. In two-dimensional analyses the out-of-plane thickness of the slave elements is, therefore, required. Generally, this thickness is the thickness specified on the section definition for the slave surface elements. However, when beam elements form the slave surface in a tie constraint pair with acoustic elements, a unit thickness in the out-of-plane direction is assumed for the beams.

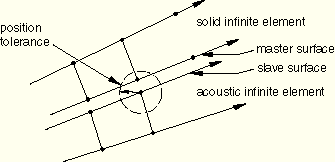

In ABAQUS/Standard you can define coupling between solid medium and acoustic medium infinite elements along the surfaces that extend to infinity. These surfaces are defined using the edges of the acoustic elements and sides numbered “2” and higher of the solid medium infinite elements. The infinite surfaces of solid medium and acoustic infinite elements can be coupled only through the use of a surface-based tie constraint. As shown in Figure 20.3.1–9, the acoustic infinite elements must be the slave elements and the edges of the acoustic infinite elements should lie within the specified position tolerance to the solid medium infinite element base facets. If the base facets of acoustic infinite elements are to be coupled to solid medium finite elements, to solid medium infinite elements, or to structural elements, either a surface-based tie constraint or acoustic-structural interaction elements can be used. Surfaces defined on solid medium infinite elements cannot be used in a surface-based tie constraint in ABAQUS/Explicit.

Figure 20.3.1–9 Use of a surface-based tie constraint to prescribe the coupling between solid medium and acoustic medium infinite elements.

Table 20.3.1–1 enumerates all possible cases. For other slave-master pairings not listed in this table, an error message will be issued.

Table 20.3.1–1 Possible slave-master surface pairings.

| Slave Surface | Master Surface | Degrees of Freedom Tied |

|---|---|---|

| Acoustic | Acoustic | Acoustic pressure |

| Acoustic | Stress | Translations |

| Stress | Acoustic | Acoustic pressure |

| Stress | Stress | Translations and/or rotations |

| Heat-Stress | Stress | Translations and/or rotations |

| Stress | Heat-Stress | Translations and/or rotations |

| Heat-Stress | Heat-Stress | Temperature, translations and/or rotations |

| The following surface pairings are available only in ABAQUS/Standard: | ||

| Heat transfer | Heat transfer | Temperature |

| Electrical-Heat | Heat transfer | Temperature |

| Heat transfer | Electrical-Heat | Temperature |

| Electrical-Heat | Electrical-Heat | Temperature and electric potential |

| Pore-Stress | Pore-Stress | Pore pressure and translations |

| Pore-Stress | Stress | Translations |

| Stress | Pore-Stress | Translations |

There are the following advantages to using a surface-based tie constraint in ABAQUS/Standard instead of defining tied contact as discussed in “Defining tied contact in ABAQUS/Standard,” Section 21.2.5:

Degrees of freedom of the slave surface nodes will be eliminated.

The tie constraint is more efficient in terms of the size of the fronts of the operator matrix because fewer master surface nodes are associated with each slave node.

Rotational degrees of freedom as well as translational degrees of freedom can be tied.

Tie constraints are much more general since they allow the use of general surfaces.

Surface offsets and shell thickness are taken into account.

In a model with multiple tie constraint definitions it is possible that the slave and master surfaces of different tie constraint definitions may intersect. If two tie constraint definitions have part or all of their master surfaces in common or if the surfaces tied are layered (i.e., the master surface of one tie constraint definition acts as the slave surface of a subsequent tie constraint definition), ABAQUS will attempt to chain the constraint definitions together. This will reduce the number of degrees of freedom and lower the computational expense, resulting in faster run times. However, in a model with multiple tie constraint definitions if nodes on the slave surface of one tie constraint definition are part of the slave surface of other tie constraint definitions, an overconstraint occurs. In most cases the overconstraint is due to the existence of redundant constraints, and it is safe to eliminate this redundancy. However, the overconstraint may also be due to conflicting constraints, in which case the problem is due to a modeling error that you should correct. It is recommended that, wherever possible, you order the slave and master surfaces of the constraint definitions to avoid intersecting slave surfaces.

If an overconstraint occurs, ABAQUS/Standard issues an error message unless the constraints are redundant or nearly redundant, as discussed below. As discussed previously, each tie constraint involves a single slave node and a set of master nodes with nonzero tie coefficents. ABAQUS/Standard considers tie constraints involving the same slave node to be nearly redundant if at least one node is common among the respective sets of master nodes with nonzero tie coefficients. In such cases, rather than issuing an error message, ABAQUS/Standard issues a warning message and only enforces one of the constraints.

The surface-based tie constraint is imposed in ABAQUS/Standard by eliminating the degrees of freedom on the slave surface; therefore, nodes on the slave surface should not be used to apply boundary conditions, nor should they be used in any subsequent tie, multi-point, equation, or kinematic coupling constraint (see “Overconstraint checks,” Section 20.6.1, for a more complete discussion of overconstraints in ABAQUS/Standard).

In contrast, ABAQUS/Explicit treats overconstraints with a penalty method, thus enforcing the constraints in an average sense; the computational cost of the analysis may increase in these cases.

In addition, if the slave surface for a tie constraint definition in ABAQUS/Explicit is part of a rigid body while the master surface comprises a deformable element- or node-based surface and the master surface acts as the slave surface in a subsequent tie constraint definition, the resolution of the resulting constraints can prove to be computationally intensive. It is recommended that, wherever possible, you order the slave and master surfaces of the constraint definitions to avoid such a situation.

The following limitations exist for tie constraints:

Surface-based tie constraints cannot be used to connect gasket elements that model thickness-direction behavior only.

A rigid surface cannot act as a slave surface in a constraint pair in ABAQUS/Standard.

A slave node of a tie constraint cannot act as a slave node of another constraint in ABAQUS/Standard.