Products: ABAQUS/Standard ABAQUS/Explicit ABAQUS/CAE

Benefits: Cohesive elements can be used to model the behavior of adhesive joints, interfaces in composites, and other situations where the integrity and strength of interfaces may be of interest.

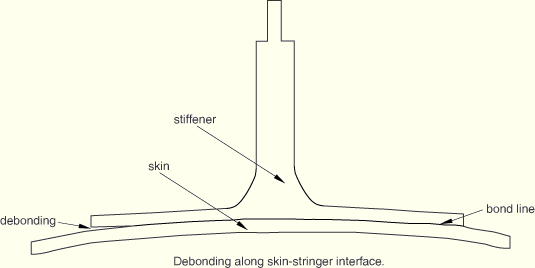

Description: A family of cohesive elements has been added. These elements can be used for detailed modeling of the deformation and damage of cohesive layers at an interface between bonded parts, such as in the applications shown in Figure 8–1 and Figure 8–2. Typically, the cohesive elements are connected to other elements in the model with surface-based tie constraints, so that the mesh used for the cohesive layer can be independent of the mesh used for the components being bonded.

Figure 8–2 Debonding along a skin-stringer interface: typical situation for traction-separation-based modeling.

The constitutive behavior of the cohesive elements can be defined with any of the following approaches:

a continuum-based constitutive model;

a uniaxial stress-based constitutive model; or

a constitutive model specified directly in terms of traction versus separation.

It is commonly desirable to model failure of bonded interfaces. Cohesive elements together with progressive damage modeling capabilities can be used to model debonding and fracture at an interface, without the need to introduce an initial crack (although this is allowed). In ABAQUS/Standard damage of a cohesive layer can be modeled only if the constitutive behavior is defined directly in terms of traction versus separation plus damage initiation and evolution models; whereas ABAQUS/Explicit also allows for damage modeling with continuum-based material models. In either case the damage behavior can be specified via material properties such as fracture toughness; however, these models do not rely on stress intensity factor calculations.

Cohesive elements are particularly attractive when interface strengths are relatively weak compared to the adjoining materials. There is some potential for numerical difficulties in the following cases:

Stiff, thin interfaces tend to reduce the stable time increment in ABAQUS/Explicit. You can mitigate this effect through mass scaling or decreasing the cohesive stiffness while preserving the fracture toughness.

Softening material response and sudden reduction in interface strength can lead to convergence difficulties in ABAQUS/Standard. Viscous regularization is provided to help overcome these difficulties. The automatic stabilization scheme in ABAQUS/Standard can also help with convergence issues.

Cohesive elements also have some limited capabilities for modeling gaskets. Compared to the family of gasket elements in ABAQUS/Standard, the cohesive elements:

are formulated to account for geometric nonlinearities;

can have mass; and

are available in both ABAQUS/Standard and ABAQUS/Explicit.

Mesh module: MeshElement Type