Product: ABAQUS/Explicit

This example illustrates the use of adaptive meshing and distortion control in deep indentation problems.

A deep indentation problem is solved for both axisymmetric and three-dimensional geometries, as shown in Figure 1.1.12–1. Each model consists of a rigid punch and a deformable blank. The punch has a semicircular nose section and a radius of 100 mm. The blank is modeled as a crushable foam with the elastic response given as follows (see Schluppkotten, 1999):

The material parameters for the isotropic hardening are given asand the density isIn both cases the punch is fully constrained except in the vertical direction. A deep indentation is made by moving the punch into the blank to a depth of 250 mm when adaptive meshing is used and to a depth of 285 mm when distortion control is used. The displacement of the punch is prescribed using the SMOOTH STEP parameter on the *AMPLITUDE option so that a quasi-static response is generated.

The blank is meshed with CAX4R elements and measures 300 × 300 mm. The punch is modeled as an analytical rigid surface using the *SURFACE, TYPE=SEGMENTS option in conjunction with the *RIGID BODY option. The bottom of the blank is constrained in the x- and z-directions, and symmetry boundary conditions are prescribed at r=0.

Two models are analyzed. For one model the blank is meshed uniformly, while for the other a graded mesh is used. For both models the blank is meshed with C3D8R elements and measures 600 × 300 × 600 mm. The punch is modeled as an analytical rigid surface using the *SURFACE, TYPE=REVOLUTION option in conjunction with the *RIGID BODY option. The bottom of the blank is fully constrained.

A single adaptive mesh domain that incorporates the entire blank is used for each model. A Lagrangian boundary region type (the default) is used to define the constraints along the bottom of the plate for both models and along the axis of symmetry in two dimensions. A sliding boundary region (the default) is used to define the contact surface on the plate. To obtain a good mesh throughout the simulation, the number of mesh sweeps is increased to 3 using the MESH SWEEPS parameter on the *ADAPTIVE MESH option. For the graded three-dimensional model the SMOOTHING OBJECTIVE parameter is set to GRADED on the *ADAPTIVE MESH CONTROLS option to preserve the gradation of the mesh while adaptive meshing is performed.

In contrast to the adaptive meshing technique, distortion control does not attempt to maintain a high-quality mesh throughout an analysis but instead tries to prevent negative element volumes or other excessive distortion from occurring during an analysis. By using distortion control, it is possible to prevent an analysis from failing prematurely when the mesh is coarse relative to the strain gradients and the amount of compression. The distortion control capability is tested for axisymmetric and three-dimensional models with a uniformly meshed blank.

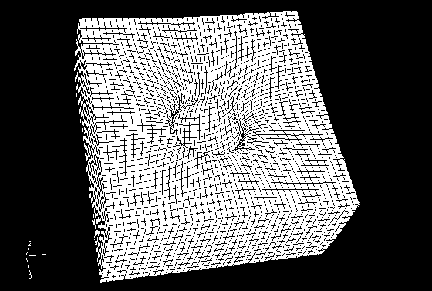

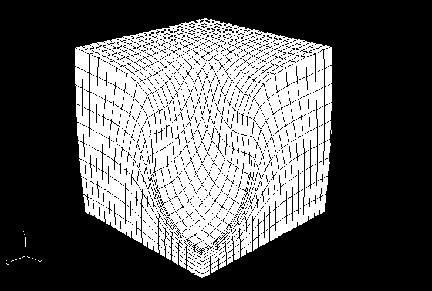

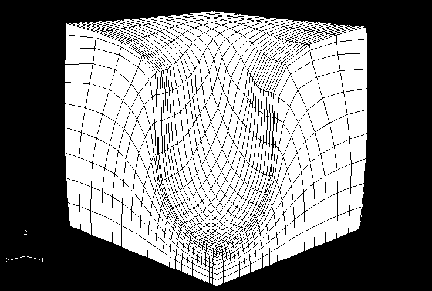

Figure 1.1.12–2 to Figure 1.1.12–4 show the initial configurations for the axisymmetric model, the three-dimensional uniform mesh model, and the three-dimensional graded mesh model. Although the punch is not shown in these figures, it is initially in contact with the plate. Figure 1.1.12–5 shows the final deformed mesh for the axisymmetric indentation. The meshing algorithm attempts to minimize element distortion both near and away from the contact surface with the punch. Figure 1.1.12–6 and Figure 1.1.12–7 show the deformed mesh of the entire blank and a quarter-symmetry, cutaway view, respectively, for the three-dimensional model with an initially uniform mesh. Even under this depth of indentation, elements appear to be nicely shaped both on the surface and throughout the cross-section of the plate.

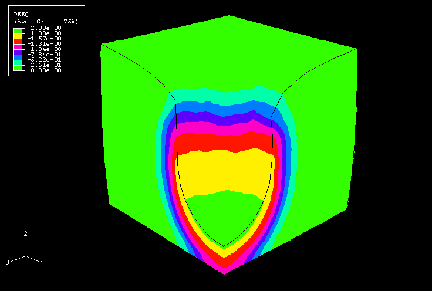

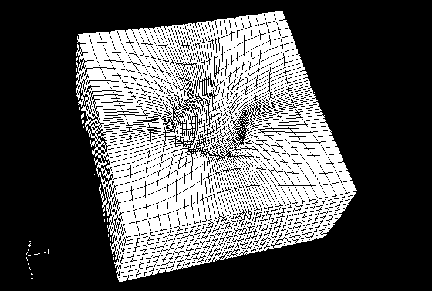

Figure 1.1.12–8 and Figure 1.1.12–9 show the deformed mesh of the entire plate and a quarter-symmetry, cutaway view, respectively, for the three-dimensional case with an initially graded mesh. Adaptive meshing with the graded smoothing objective preserves the mesh gradation throughout the indentation process while simultaneously minimizing element distortion. Preserving mesh gradation in adaptivity problems is a powerful capability that allows mesh refinement to be concentrated in the areas of highest strain gradients. A contour plot of equivalent plastic strain for the graded mesh case is shown in Figure 1.1.12–10.

Figure 1.1.12–11 shows the final deformed mesh for the axisymmetric indentation using distortion control without adaptive meshing. Figure 1.1.12–12 and Figure 1.1.12–13 show the deformed mesh of the entire blank and a quarter-symmetry, cutaway view, respectively, for the three-dimensional model with an initially uniform mesh using distortion control without adaptive meshing. The distortion control simply prevents element distortion near the contact surface with the punch. Without distortion control both of the analyses fail prematurely under this depth of indentation.

Case 1 using adaptive meshing.

Case 2 with a uniform mesh using adaptive meshing.

Case 2 with a graded mesh using adaptive meshing.

External file referenced by Case 2.

Case 1 using distortion control.

Case 2 with a uniform mesh using distortion control.

Schluppkotten, J., Investigation of the ABAQUS Crushable Foam Plasticity Model, Internal report of BMW AG, 1999.

Figure 1.1.12–6 Deformed configuration for the three-dimensional model with an initially uniform mesh.

Figure 1.1.12–7 Quarter-symmetry, cutaway view of the deformed configuration for the three-dimensional model with an initially uniform mesh.

Figure 1.1.12–8 Deformed configuration for the three-dimensional model with an initially graded mesh.

Figure 1.1.12–9 Quarter-symmetry, cutaway view of the deformed configuration for the three-dimensional model with an initially graded mesh.

Figure 1.1.12–10 Contours of equivalent plastic strain for the three-dimensional model with an initially graded mesh.