Products: ABAQUS/Standard ABAQUS/Explicit

DC1D2 DC1D3

DC2D3 DC2D4 DC2D6 DC2D8

DCAX3 DCAX4 DCAX6 DCAX8

CAX3T CAX4RHT CAX4RT CAX4T

CPE3T CPE4RHT CPE4RT CPE4T CPE6MHT CPE6MT

CPS3T CPS4RT CPS4T CPS6MT

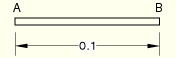

The geometry is shown above. A uniform mesh with 10 elements along the length of the bar is used. The thickness and width of the bar are each 0.01 m. In ABAQUS/Standard a steady-state simulation is performed, while in ABAQUS/Explicit a transient simulation is performed. The total simulation time in the latter case is 2500 seconds. This provides enough time for the transient solution to reach steady-state conditions in this problem.

Material:Conductivity = 55.6 W/m°C, specific heat = 460.0 J/kg°C, density = 7850 kg/m3. At end B emissivity = 0.98, Stefan-Boltzman constant = 5.67 × 10–8 W m2/ K4.

For the coupled temperature-displacement elements dummy mechanical properties are used to complete the material definition.

Boundary conditions:

Prescribed temperature of 1000 K at end A. Radiation to ambient temperature of 300 K at end B. No heat flux perpendicular to AB.

Loading:

Zero internal heat generation.

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test T2 from NAFEMS publication TNSB, Rev. 3, “The Standard NAFEMS Benchmarks,” October 1990.

Target solution: Temperature at B=927 K (653.85°C).

DC1D2 elements.

DC1D3 elements.

DC2D3 elements.

DC2D4 elements.

DC2D6 elements.

DC2D8 elements.

DCAX3 elements.

DCAX4 elements.

DCAX6 elements.

DCAX8 elements.

CPE4RHT elements.

CPE4RT elements.

CPE4T elements.

CPE6MHT elements.

CPE6MT elements.

CPS4RT elements.

CPS4T elements.

CPS6MT elements.

CAX4RHT elements.

CAX4RT elements.

CAX4T elements.

CAX6MHT elements.

CAX6MT elements.

C3D8RHT elements.

C3D8RT elements.

C3D8T elements.

CAX3T elements.

CAX4RT elements.

CPE3T elements.

CPE4RT elements.

CPS3T elements.

CPS4RT elements.

C3D4T elements.

C3D6T elements.

C3D8RT elements.