Product: ABAQUS/Standard

Linear elastic, Young's modulus = 100 GPa, Poisson's ratio = 0.3.

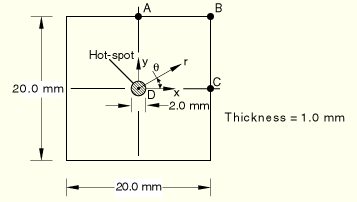

Boundary conditions:

A quarter-section is modeled with the symmetry conditions ![]() 0 along

0 along ![]() 0 and

0 and ![]() 0 along

0 along ![]() 0.

0.

Loading:

Within the hot-spot, thermal strain (![]() ) = 1.0 × 10–3. Outside the hot-spot, thermal strain (

) = 1.0 × 10–3. Outside the hot-spot, thermal strain (![]() ) = 0.

) = 0.

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test T1 from NAFEMS publication TNSB, Rev. 3, “The Standard NAFEMS Benchmarks,” October 1990.

Target solution: ![]() at point D (outside the hot-spot) = 50.0 MPa.

at point D (outside the hot-spot) = 50.0 MPa.

The results are shown in the following table. The values enclosed in parentheses are percentage differences with respect to the reference solution.

*A comparison of the results for reduced-integration and full-integration elements indicates that the full-integration elements perform significantly better for problems with stress concentrations of this type.CPS3 elements.

CPS4 elements.

CPS6 elements.

CPS8 elements.

CPS4I elements.

CPS6M elements.

CPS4R elements.

CPS8R elements.