Products: ABAQUS/Standard ABAQUS/Explicit

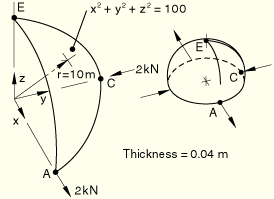

The model is illustrated in the figure above. In addition, two input files are provided for the continuum shell element model to illustrate the use of the STACK DIRECTION=ORIENTATION parameter to define the element thickness (stacking) direction independent of the nodal connectivity using a spherical system.

Material:Linear elastic, Young's modulus = 68.25 GPa, Poisson's ratio = 0.3.

Boundary conditions:

![]() 0 at point E. Along edge AE, symmetry about the z–x plane. Along edge CE, symmetry about the y–z plane.

0 at point E. Along edge AE, symmetry about the z–x plane. Along edge CE, symmetry about the y–z plane.

Loading:

Concentrated radial loads of 2 kN outward at A, inward at C.

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test LE3 from NAFEMS publication TNSB, Rev. 3, “The Standard NAFEMS Benchmarks,” October 1990.

Target solution: ![]() 185 mm at point A.

185 mm at point A.

The values enclosed in parentheses are percentage differences with respect to the reference solution.

| Element | ||

|---|---|---|

| S3/S3R | 0.080 (–57%) | 0.161 (–13%) |

| S4 | 0.083 (–55%) | 0.175 (–5%) |

| S4R | 0.180 (–2.7%) | 0.180 (–2.7%) |

| S4R* | 0.072 (–61%) | 0.170 (–8.1%) |

| S4R** | 0.058 (–68%) | 0.168 (–9.1%) |

| S4R5 | 0.190 (2.7%) | 0.183 (–1.1%) |

| S8R | 0.101 (–45%) | 0.178 (–3.8%) |

| S8R5 | 0.179 (–3.2%) | 0.185 (0.0%) |

| S9R5 | 0.179 (–3.2%) | 0.185 (0.0%) |

| STRI3 | 0.173 (–1.2%) | 0.185 (0.0%) |

| STRI65 | 0.169 (–8.6%) | 0.182 (–1.6%) |

| SC6R | 0.088 (–52.4%) | 0.167 (–9.7%) |

| SC8R | 0.210 (13.5%) | 0.188 (1.6%) |

| SC8R*** | 0.194(4.9%) | 0.185(0.0%) |

| SAXA12**** | 0.179 (–3.2%) | |

| SAXA22**** | 0.178 (–3.8%) |

The continuum shell element meshes using the STACK DIRECTION=ORIENTATION parameter yield identical results to the continuum shell element meshes in which the thickness direction is defined by the element nodal connectivity.

S3/S3R elements.

S4 elements.

S4R elements.

S4R elements with enhanced hourglass control.

S4R5 elements.

S8R elements.

S8R5 elements.

S9R5 elements.

STRI3 elements.

STRI65 elements.

SAXA12 elements.

SAXA22 elements.

SC6R elements.

SC8R elements.

SC6R elements using the STACK DIRECTION=ORIENTATION parameter with a spherical orientation system to define the element thickness direction.

SC8R elements using the STACK DIRECTION=ORIENTATION parameter with a spherical orientation system to define the element thickness direction.

SC8R elements using *SHELL GENERAL SECTION to define section properties.

S4R elements with enhanced hourglass control.

SC8R elements with the default “relax stiffness” hourglass control.