Products: ABAQUS/Standard ABAQUS/Explicit

This example provides verification of the transverse shear stress calculations in ABAQUS for multilayer composite shells and demonstrates the use of the plane stress orthotropic failure measures. A discussion of the transverse shear stresses obtained by composite solids in ABAQUS/Standard is also included. The problem consists of a two- or three-layer plate subjected to a sinusoidal distributed load, as described by Pagano (1969). The resulting transverse shear and axial stresses through the thickness of the plate are compared to two existing analytical solutions by Pagano (1969). The first solution is derived from classical laminated plate theory (CPT), while the second is an exact solution from linear elasticity theory.

A schematic of the model is shown in Figure 1.1.3–1. The structure is a composite plate composed of orthotropic layers of equal thickness. It is simply supported at its ends and bounded along its edges to impose plane strain conditions in the ![]() -direction. Each layer models a fiber/matrix composite with the following properties:

-direction. Each layer models a fiber/matrix composite with the following properties:

| 172.4 GPa (25 × 106 lb/in2) | |

| 6.90 GPa (1.0 × 106 lb/in2) | |

| 3.45 GPa (0.5 × 106 lb/in2) | |

| 1.38 GPa (0.2 × 106 lb/in2) | |

| 0.25 |

In addition to the methods outlined above, a third method of stacking continuum shell elements is used to specify the lay-up definition for a composite model. This method can be used effectively to study localized behavior, since continuum shell elements handle high aspect ratios between the in-plane dimension and the thickness dimension well.

The lay-up definition for the continuum (solid) element model in ABAQUS/Standard is specified using the *SOLID SECTION, COMPOSITE option. The thickness, material name, and orientation definition for each layer are specified on the data lines following the *SOLID SECTION option.

A distributed load with a sinusoidal distribution in space, ![]() , is applied to the top of the composite plate. In ABAQUS/Standard the load is applied using user subroutine DLOAD in a static linear analysis step. In addition, an ABAQUS/Standard input file is included that demonstrates the use of the DCOUP3D element to apply this distributed load. In ABAQUS/Explicit the load is applied instantaneously at time

, is applied to the top of the composite plate. In ABAQUS/Standard the load is applied using user subroutine DLOAD in a static linear analysis step. In addition, an ABAQUS/Standard input file is included that demonstrates the use of the DCOUP3D element to apply this distributed load. In ABAQUS/Explicit the load is applied instantaneously at time ![]() 0.

0.

Two composite plates are analyzed in this example. The first is a two-layer plate with the fibers oriented parallel and orthogonal to the ![]() -axis in the bottom and top layer, respectively. In the second plate, which has three layers of equal thickness, the fibers in the outer layers are oriented parallel to the

-axis in the bottom and top layer, respectively. In the second plate, which has three layers of equal thickness, the fibers in the outer layers are oriented parallel to the ![]() -axis, while the fibers in the middle layer are orthogonal to the

-axis, while the fibers in the middle layer are orthogonal to the ![]() -axis. The span-to-thickness ratio of the plates,

-axis. The span-to-thickness ratio of the plates, ![]() , is varied from 4 to 30 in the ABAQUS/Standard analysis; in ABAQUS/Explicit this ratio is 4 throughout the analysis.

, is varied from 4 to 30 in the ABAQUS/Standard analysis; in ABAQUS/Explicit this ratio is 4 throughout the analysis.

A 1 × 10 mesh of second-order S8R shell elements is used to model the plates in ABAQUS/Standard. A 2 × 10 mesh of first-order S4R shell elements is used to model the plates in ABAQUS/Explicit. The S4R, S8R, and S8RT shell elements are well-suited for modeling thick composite shells since they account for transverse shear flexibility. Five integration points are specified through the thickness of each layer with the models that use the *SHELL SECTION option. This provides sufficient data to describe the stress distributions through the thickness of each layer. For the models that use the *SHELL GENERAL SECTION option, only three points are available for output. (Since the analysis is linear elastic, three points are sufficient to determine all fields through the thickness.) The plate with the lowest span-to-thickness ratio is also analyzed with ABAQUS/Standard using a 1 × 10 mesh of second-order C3D20R composite solid elements.

To illustrate the stacking capability of continuum shell elements, several meshes are provided for the three-layer plate with the lowest span-to-thickness ratio. The first model is a 1 × 10 mesh of SC8R elements using a single element through the thickness with a composite section definition. The second model consists of three elements stacked in the thickness direction, each element representing a single layer of the 0/90/0 composite plate. Additional models with 6, 12, and 24 elements through the thickness are provided. In these models each composite layer is modeled with 2, 4, and 8 elements through the thickness, respectively.

Additional input files using the SC8R element are included to illustrate the use of the STACK DIRECTION parameter to define the stacking and thickness direction independent of the element nodal connectivity.

The plane stress orthotropic failure measures are defined in “Plane stress orthotropic failure measures,” Section 10.2.3 of the ABAQUS Analysis User's Manual. To demonstrate their use, let the limit stresses and limit strains be given as follows (defined with *FAIL STRESS and *FAIL STRAIN):

| Stress Values: | |||||

| (GPa) | 2.07 × 10–4 | –8.28 × 10–5 | 3.45 × 10–6 | –1.03 × 10–5 | 6.89 × 10–6 |

| (lb/in2) | 30.0 | –12.0 | 0.5 | –1.5 | 1.0 |

| Strain Values: | |||||

| 17. × 10–2 | –7. × 10–2 | 5. × 10–2 | –1.3 × 10–2 | 11. × 10–2 |

The results for each of the analyses are discussed in the following sections.

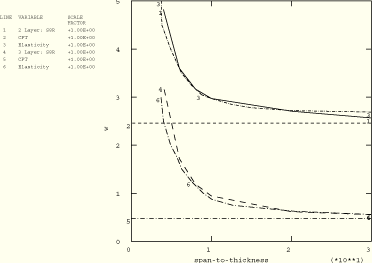

Figure 1.1.3–2 shows the maximum ![]() -displacement as a function of the span-to-thickness ratio of the two- and three-layer plates in a normalized form as

-displacement as a function of the span-to-thickness ratio of the two- and three-layer plates in a normalized form as

![]()

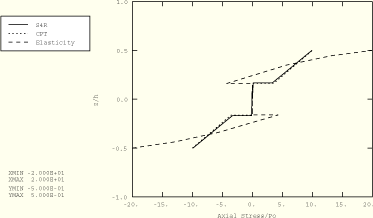

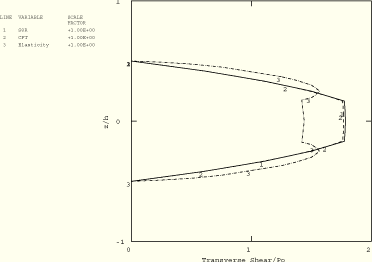

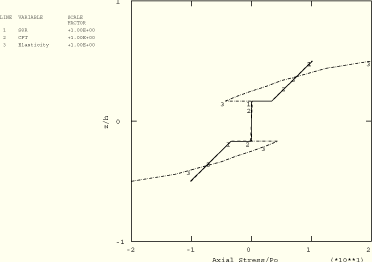

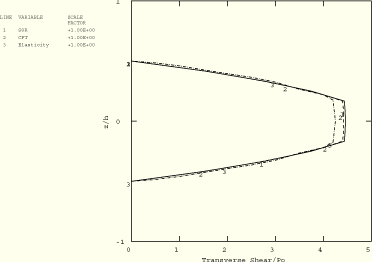

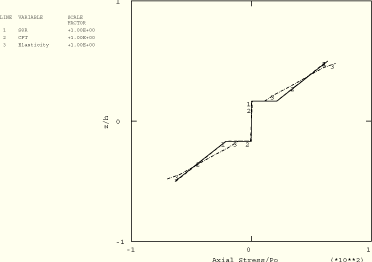

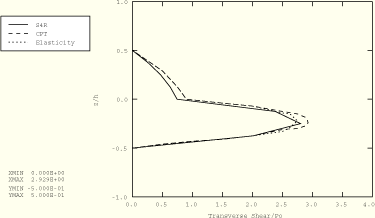

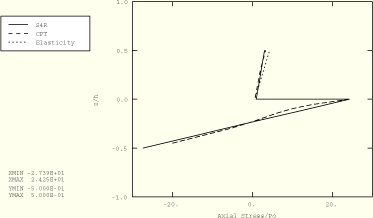

For ![]() 4, Figure 1.1.3–3 and Figure 1.1.3–4 show the transverse shear stress (TSHR13) and the axial stress (S11) distributions through the plate thickness for the two-layer plate normalized as

4, Figure 1.1.3–3 and Figure 1.1.3–4 show the transverse shear stress (TSHR13) and the axial stress (S11) distributions through the plate thickness for the two-layer plate normalized as

![]()

![]()

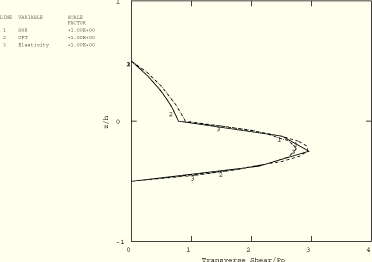

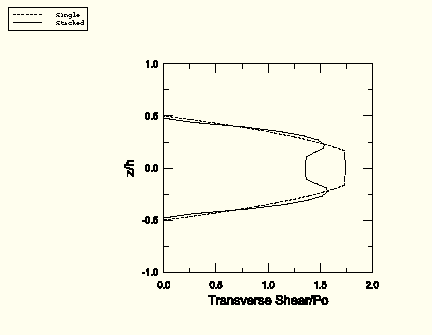

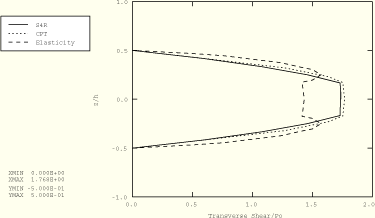

Figure 1.1.3–7 compares the transverse shear distribution of the continuum shell meshes using a single element and 24 elements stacked in the thickness direction. For the case with a single element in the thickness direction the results come close to the CPT prediction. With mesh refinement in the thickness direction, the results agree with the elasticity solution.

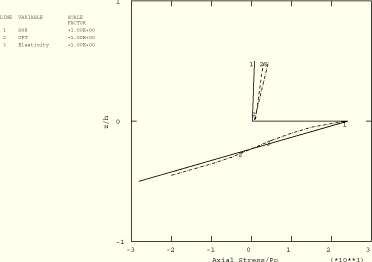

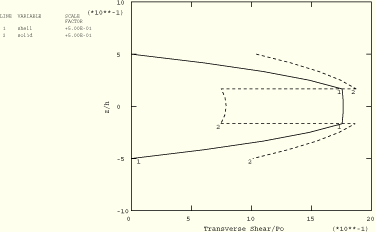

Figure 1.1.3–8 compares the transverse shear stress distribution obtained with the solid element model with the shell element result. The figure shows that the transverse shear stresses predicted by solid elements do not vanish at the free surfaces of the structure. It also shows that the stress is discontinuous at layer interfaces. The reason for this is that in the composite solid element, the transverse shear stresses are obtained directly from the displacement field in contrast to the shell element, where the transverse shear stresses are obtained from an equilibrium calculation. These deficiencies decrease if the number of solid elements used in the discretization through the section thickness is increased. Although the transverse shear stresses are inaccurate, the displacement field and components of stress in the plane of the layer (not shown here) are in much better agreement with the analytical result. In fact, these results are somewhat better than the results obtained with the S8R elements. The composite solid elements were not used to analyze the thinner plates since the solid elements would not have any advantage over plate elements in that case.

For ![]() 10, Figure 1.1.3–9 and Figure 1.1.3–10 show that the transverse shear and axial stress distributions of the finite element results—along with the CPT predictions—agree with elasticity theory. The stress distributions become more accurate with increasing span-to-thickness ratio (as the plate becomes thinner in comparison to the span).

10, Figure 1.1.3–9 and Figure 1.1.3–10 show that the transverse shear and axial stress distributions of the finite element results—along with the CPT predictions—agree with elasticity theory. The stress distributions become more accurate with increasing span-to-thickness ratio (as the plate becomes thinner in comparison to the span).

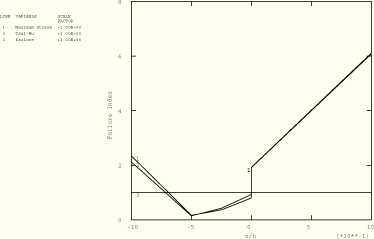

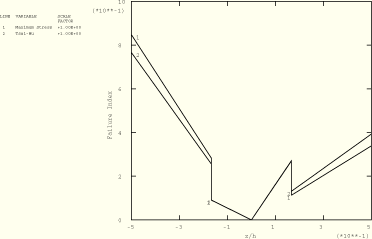

In Figure 1.1.3–11 and Figure 1.1.3–12 the maximum stress theory and Tsai-Wu theory failure indices are plotted as a function of the normalized distance from the midsurface for the two- and three-layer cases, respectively. The indices are calculated at the center of the plate for S8R elements with ![]() 4. Values of the failure index greater than or equal to 1.0 indicate failure. Discontinuous jumps in the failure index occur at layer boundaries as a result of the orientation of the material. The strain levels are well below those required for failure, so no strain-based failure indices are plotted.

4. Values of the failure index greater than or equal to 1.0 indicate failure. Discontinuous jumps in the failure index occur at layer boundaries as a result of the orientation of the material. The strain levels are well below those required for failure, so no strain-based failure indices are plotted.

The explicit dynamic analysis is run for a sufficiently long time so that a quasi-static state is reached—that is, the plates are in steady-state vibration. Since step loadings are applied, static solutions of stresses can be obtained as half of their vibration amplitudes.

Figure 1.1.3–13 and Figure 1.1.3–14 show the transverse shear stress (TSHR13) and the axial stress (S11) distributions through the plate thickness for the two-layer S4R model normalized as:

![]()

![]()

Figure 1.1.3–15 and Figure 1.1.3–16 show the corresponding results for the three-layer plate. In Figure 1.1.3–17 and Figure 1.1.3–18, the maximum stress theory and Tsai-Wu theory failure indices are plotted as a function of the normalized distance from the midsurface for the two- and three-layer cases, respectively. The indices are calculated at the center of the plate. Values of the failure index greater than or equal to 1.0 indicate failure. Discontinuous jumps in the failure index occur at layer boundaries due to the orientation of the material. The strain levels are well below those required for failure, so no strain-based failure indices are plotted.

Three-layer plate with ![]() 4 using S8R elements.

4 using S8R elements.

User subroutine defining nonuniform distributed load for use with compositeshells_s8r.inp.

Three-layer plate with ![]() 4 using S8R elements and *SHELL GENERAL SECTION.

4 using S8R elements and *SHELL GENERAL SECTION.

User subroutine DLOAD used in compositeshells_s8r_gensect.inp.

S4 element model.

User subroutine DLOAD used in compositeshells_s4.inp.

S4 element model with *SHELL GENERAL SECTION.

User subroutine DLOAD used in compositeshells_s4_gensect.inp.

S4 element model loaded using a DCOUP3D element.

S4R element model.

User subroutine DLOAD used in compositeshells_s4r.inp.

S4R element model with *SHELL GENERAL SECTION.

User subroutine DLOAD used in compositeshells_s4r_gensect.inp.

C3D20R composite solid element model.

User subroutine DLOAD used in compositeshells_c3d20r.inp.

SC8R model using STACK DIRECTION=1.

SC8R model using STACK DIRECTION=2.

SC8R model using STACK DIRECTION=3.

SC8R model using *SHELL GENERAL SECTION.

Three-layer plate with SC8R elements, single element through the thickness.

Three-layer plate with SC8R elements, three elements stacked through the thickness.

Three-layer plate with SC8R elements, six elements stacked through the thickness.

Three-layer plate with SC8R elements, twelve elements stacked through the thickness.

Three-layer plate with SC8R elements, twenty-four elements stacked through the thickness.

User subroutine DLOAD used with the SC8R models.

Three-layer plate modeled with S4R elements.

Three-layer plate modeled with SC8R elements.

Three-layer plate modeled with SC8R elements using STACK DIRECTION=1.

Three-layer plate modeled with SC8R elements using STACK DIRECTION=2.

Three-layer plate modeled with SC8R elements using STACK DIRECTION=3.

Three-layer plate with a different thickness and modeled with S4R elements.

Two-layer plate modeled with S4R elements.

Two-layer plate modeled with S4R elements.

Two-layer plate modeled with SC8R elements.

Pagano, N. J., “Exact Solutions for Composite Laminates in Cylindrical Bending,” Journal of Composite Materials, vol. 3, pp. 398–411, 1969.

Figure 1.1.3–2 Maximum deflection of two- and three-layer plates with various span-to-thickness ratios; ABAQUS/Standard analysis.

Figure 1.1.3–3 Transverse shear stress distribution through the thickness of a two-layer plate (![]() 4); ABAQUS/Standard analysis.

4); ABAQUS/Standard analysis.

Figure 1.1.3–4 Axial stress distribution through the thickness of a two-layer plate (![]() 4); ABAQUS/Standard analysis.

4); ABAQUS/Standard analysis.

Figure 1.1.3–5 Transverse shear stress distribution through the thickness of a three-layer plate (![]() 4); ABAQUS/Standard analysis.

4); ABAQUS/Standard analysis.

Figure 1.1.3–6 Axial stress distribution through the thickness of a three-layer plate (![]() 4); ABAQUS/Standard analysis.

4); ABAQUS/Standard analysis.

Figure 1.1.3–7 Comparison of transverse shear stress distribution for single and 24 continuum shells stacked through the thickness; ABAQUS/Standard analysis.

Figure 1.1.3–8 Transverse shear stress distribution through the thickness of a three-layer plate (![]() 4): shells versus solid elements; ABAQUS/Standard analysis.

4): shells versus solid elements; ABAQUS/Standard analysis.

Figure 1.1.3–9 Transverse shear stress distribution through the thickness of a three-layer plate (![]() 10); ABAQUS/Standard analysis.

10); ABAQUS/Standard analysis.

Figure 1.1.3–10 Axial stress distribution through the thickness of a three-layer plate (![]() 10); ABAQUS/Standard analysis.

10); ABAQUS/Standard analysis.

Figure 1.1.3–11 Maximum stress theory and Tsai-Wu theory (![]() 0.0) failure indices as a function of normalized distance from the midsurface. Two-layer plate,

0.0) failure indices as a function of normalized distance from the midsurface. Two-layer plate, ![]() 4; ABAQUS/Standard analysis.

4; ABAQUS/Standard analysis.

Figure 1.1.3–12 Maximum stress theory and Tsai-Wu theory (![]() 0.0) failure indices as a function of normalized distance from the midsurface. Three-layer plate,

0.0) failure indices as a function of normalized distance from the midsurface. Three-layer plate, ![]() 4; ABAQUS/Standard analysis.

4; ABAQUS/Standard analysis.

Figure 1.1.3–13 Transverse shear stress distribution through the thickness of a two-layer plate; ABAQUS/Explicit analysis.

Figure 1.1.3–14 Axial stress distribution through the thickness of a two-layer plate; ABAQUS/Explicit analysis.

Figure 1.1.3–15 Transverse shear stress distribution through the thickness of a three-layer plate; ABAQUS/Explicit analysis.

Figure 1.1.3–16 Axial stress distribution through the thickness of a three-layer plate; ABAQUS/Explicit analysis.