Andrew Wiens - Study Abroad SU10

Contents

About the Trip

Albert Einstein once said, "Israel can win the battle for survival only by developing expert knowledge in technology." As we learned, the Technion, located in Haifa, Israel, was conceived largely to realize this ambition; it is the oldest technical institution for higher learning in that part of the world. Over the years it has grown from its humble roots in downtown Haifa to become the heart of Israeli technology and industry. As a lowly undergraduate who just finished his freshman year, being invited to the Technion halfway around the world was no small matter.

Our visit to the Technion, covering five days of the trip, introduced us to nearly every engineering department at the university. The departments of Electrical, Mechanical, Aerospace, Computer Science, and Biomedical Engineering were among those that we had the privilege to see. Professors, students, and researchers presented their departments’ projects and academic disciplines with slide show presentations and live demonstrations. Projects at the Technion ranged from flying quadcopters to surgical aids, from “fire-fighting” robots and hexapods to bipedal robots and UAV airplanes. As we learned, such tangible engineering projects are a staple of an undergraduate education at the Technion.

In addition to learning about engineering at the Technion, we also actively participated in engineering during our many lab sessions. We used methods and concepts such as proportional-integral-derivative algorithms to solve problems such as balancing a pole with an electronic stepper motor. Other labs served more as an overview of a specific area of signal processing by introducing us to areas such as audio signal processing and speech synthesis.

On the whole, the trip inspired me to seek out my own independent study project. Although we do have the senior design projects at the end of our undergraduate careers here at Washington University, students at the Technion often complete two or more research or design projects as undergraduates in addition to working 15+ hours a week in industry! In light of this it seems that, rather than distracting from an education in electrical engineeirng, engaging in self-motivated projects can be a rewarding experience that enhances and expands students' knowledge of electronics and real-world problem solving.

Report

While visiting the Technion we saw a few helicopter projects. One project, which was completed by a team of two undergraduate students, was a remotely controlled quadcopter utilizing four vertical propellers to generate lift and control. Another project, which was an ongoing research project conducted by graduate students, faculty members, and lab technicians, was a single-rotor helicopter designed to autonomously follow and track a land-based vehicle with a target application for urban law enforcement situations. In order to understand these projects better the devices and methods used to localize an unmanned helicopter’s position must first be investigated.

UAV Design – Sensors for Object Avoidance with Unmanned Helicopters

There are many problems encountered when designing a robotic helicopter. First, a stable, airworthy helicopter platform must be designed. This task alone encompasses a vast range of disciplines including materials, mechanics, control, structure, and aerospace engineering. Luckily, there are many commercial small-scale helicopter platforms available on the market, the use of which relieves the electrical engineer from the task of designing the helicopter platform. Once a worthy helicopter platform is obtained, control and navigational systems must be designed to enable the robot to travel about its environment. The focus of this report is on the latter and explores the use of various types of sensors to provide object avoidance for a small-scale autonomous robotic helicopter.

Ultrasound

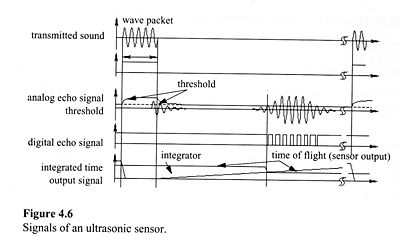

Ultrasonic sensors are one means to enable the robot to determine its distance from nearby objects. Ultrasonic distance sensors operate by the time-of-flight paradigm: a wave packet is emitted from a transmitter and the onboard computer waits to hear the packet echoed back to a receiver. Using the difference between the time of arrival and the time of transmission, the distance can be calculated based on the speed of sound.

This technique poses a few problems. First, because the speed of sound is relatively slow, the propagation time of the ultrasonic waves is quite high leading to a slow refresh rate. For example, finding the distance of an object that is only three meters away with a single ultrasonic sensor takes twenty milliseconds resulting in a refresh rate limited to 50 Hz.

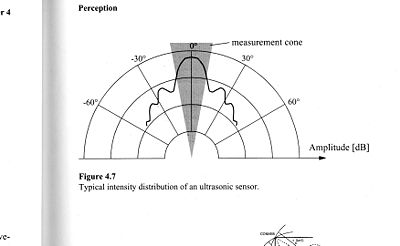

Additionally, the attenuation of ultrasonic waves in air is quite high and results in a low effective distance; typical robotic ultrasonic sensors have a range of no more than five meters. Also, ultrasonic waves propagate in a cone-like shape and cannot be used to determine the distance of a small point. Thus, the sensor’s spacial resolution decreases as the object’s distance increases until the distance is large enough to render the sensor unusable.