Gravicase

Contents

Project Overview

Computers, tablets, smartphones all of these objects cost hundreds of dollars. We buy them for their sleek designs and fluid screens and buttons. Then in order to protect them, we seal them away in big bulky cases, trapping our smooth phones or computers behind sturdy yet cumbersome plastic while we cover the vibrant screens with a dull, always cloudy screen protector. And the worst part of all? We still hold our breath when we drop our hundred dollar investments until we see the screen unharmed. There is no confidence in the ability of current conventional cases to protect our electronics.

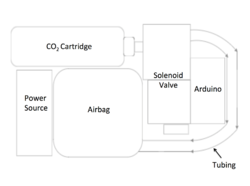

Our group has proposed Gravicase as a proof of concept solution to this problem. With Gravicase, we hope to create a device which can be attached to the back of one's personal electronics. Gravicase aims to maximize protection while minimizing the negative impact of one's experience with their electronics. Gravicase protects your precious possessions by deploying an airbag that envelopes your phone, computer, tablet, etc. and protects it from fall damage. While we do not have a quantifiable value for the effectiveness of Gravicase vs. conventional electronics protection, the effect of adding airbags in cars have improved survival rates in head on collisions by 30% (section 4 of link), even as the strength of the other materials in cars decreases (changes from heavier stronger steel to lighter aluminum). Similarly side airbags have increased survival rates in side collisions by 50% (section 4 of link). Gravicase adopts a similar approach. By surrounding your electronics with an airbag on all sides, Gravicase protects from blunt force drop damage at any angle.

Gravicase is an Arduino controlled device which attaches to your personal electronic devices and, when dropped, deploys a CO2 powered airbag that envelops and protects whatever it is attached to. The Arduino uses an accelerometer to sense when it is being dropped, as well as if it tumbling, so that it can accurately and safely differentiate a fall compared to other movements one would take (aka walking, running, jumping, etc). This dual safety measure allows for Gravicase to avoid activating in your bag or pocket and be ready when it counts! We will detail how we accomplished this as well as more in depth measures we took for safety and execution in the "Objective" and "Designs and Solutions" sections of our wiki.

Link to GraviCase Log: here

Link to the slides from our class presentation on Gravicase from 9.29.2017: here

Team Members

- Matt Rocco

- Michael Morgan

- Andrew O'Sullivan (TA)

Objectives

Our project objectives are as follows:

- 1) Designing a device which allows us to lay out all of the components of our device

- Houses the airbag in the middle so that it is centered on the device for even protection

- Trying to minimize our layout to be as discreet and form fitting as possible

- 2) Writing Arduino code which is both effective as well as safe

- Preventing our design from popping in your pocket or bag or any time other than when it is falling

- Developing durable and robust code which can handle constant data monitoring, and quickly analyze when it is being dropped from the real world information it receives

- 3) Creating an airtight system

- Preventing CO2 from escaping so that it is pressurized and ready to go when the device is dropped

- Ensuring that all of the CO2 cartridge's volume ends up in the airbag to maximize its efficiency

- Preventing CO2 from escaping so that it is pressurized and ready to go when the device is dropped

- 4) Designing an airbag which can absorb a blunt force impact as well as be easily deflated in order to be reused

- Sewing a shape that protects all parts of the device when inflated

- Finding a material that can easily be worked with as well as fits the design needs we desire (durability, as well as reusability)

- Protects all parts of the device (ex. phone screen as well as back and sides)

- Maintaining a compact and foldable form but being able to achieve the functions described above

- 5) The ability to pop the canister so that it is ready to fill the airbag upon being dropped

- Focusing on popping the canister prior to when it is necessary so that there is no delay related to the CO2 when the device is dropped

Challenges

- Safety

- Premature detonation of our airbag system (Literally blowing your pants off)

- Working with pressurized systems of CO2 which have the possibilities of exploding

- Cost

- Airbags are expensive and typically designed to only be used once

- CO2 canisters are going to be needed in large quantities for testing (this will inflate our actual cost)

- Power

- We need to power both an Arduino as well as a 12V solenoid valve, this requires an external power supply which will be part of our device

- Size

- Creating a device small enough to maintain the shape and convenience of your device without compromising safety or efficacy

- Working with sizing and space constraints of our parts and fitting them together in the most efficient way possible

- Airbag

- Building an airbag which will deploy in such a way as to maximize protection but still deploy in time with no snags.

- Able to absorb a blunt force impact

- Easily deflatable for reuse

- Arduino

- Code which effectively filters information in order to accurate determine if it is falling

Costs

Hardware and Circuit

- Arduino Uno (Provided by TA)

- Arduino Accelerometer (GY-521) ~ Provided, link

- STP36NF06L Transistor ~ Provided, link with link to data sheet

Valve and Tubing

- Threaded 3/8" 24 threads / inch, 16g CO2 Cartridges ~ $47.95 for 50, link

- McMaster-Carr tube ~ $15.20, link

- CO2 (3/8") to Regulator (1/4") Converter (Lafed by our TA)

- Pressure Regulator (1/4") ~ $22.48, link

- Regulator(1/4") to Valve (1/4") Attachment ~ $2.39, link

- Electronic (1/4") Solenoid Valve ~ $12, link

- Valve (1/4") to Hose Attachment (1/4") ~ $3.12, link

- Pneumatic Tubing (1/4" ID) ~ $7.31, link

Airbag Material

- Tyvek Cloth ~ $7.35, link

"Teflon Tape (Provided by instructor)

Total Cost ~ $117.69

Estimated Unit Cost ~ $46.54

- Estimated Unit Cost is determined by scaling our cost based upon mass production. In several cases, we had to buy bulk amount of materials but ultimately only used a small percentage of it. The estimated unit cost accounts for this and represents the cost to make multiple Gravicases.

- Example: we spent $7.31 to get 10 feet of pneumatic tubing but ultimately used a little bit less than half of a foot of it. Therefore we would be able to build 19 more Gravicases without having to spend any additional money on pneumatic tubing.

- This was the case for the Tyvek material (1/10), pneumatic tubing (1/20), CO2 canisters (most of their use was in testing causing a big spike in our total cost), and the McMaster-Carr tube (1/25).

- Values are ratios of the amount used compared to the total bought

Gantt Chart

Design Solutions:

CO2 to Airbag Design In order to get our device started, we need to be able to reliably puncture CO2 canisters. With the help of our TA, we decided to custom make a part which would allow us to simultaneously screw in and pop a CO2 canister (schematic and 3D model shown below).

It also serves the secondary purpose of being an adapter for the 3/8" male of the CO2 canisters to the 1/4" female regulator. In order to break the seal of the canister, we designed the part so that it could hold a small, hollow metal pipe (accomplished by having a small bevel in the part for the tube to rest on) that would serve as a "needle" to punch through the thin perforated metal covering the opening of the CO2 container. We threaded the female side of our part (connecting to the CO2) so that it would securely hold the canister while also allowing us to screw in our CO2 and use torque to our advantage. The male side of the part is connected to a pressure regulator, which steps down the pressure coming out of the CO2 canister from approximately 800-900 PSI to a much more manageable 150 PSI (we set this value using the regulator).

We then connected the regulator to our solenoid valve through another adapter, this time a 1/4" male to 1/4" male. The solenoid valve is a 12V DC normally closed valve which is hooked up to a circuit controlled by the Arduino. The valve is normally closed this prevents the air from the CO2 canister from escaping, however, when voltage runs through the valve it opens allowing air to flow and thus fill the airbag. The valve is where the electronic and mechanical components of our project meet, more of this will be discussed in the next section. On the other end of our valve was the 1/4" hose nozzle adapter which we used to secure the pneumatic tubing. Lastly, attached to the end of our tubing is the airbag, secured with an O-ring washer system so that it is directing the air solely into the airbag. In order to ensure that our path from canister to airbag was airtight, we used Teflon tape to seal all of the threaded components of our system including needing to Teflon tape each individual CO2 canister to ensure maximum efficiency.

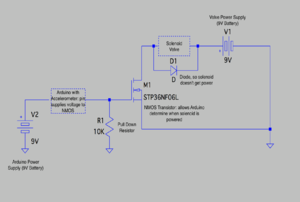

Arduino and Circuit Design In order to control the solenoid valve we designed a circuit which regulates when the valve receives voltage. The valve is normally closed, therefore as long as it has no voltage running through, no air will flow and the airbag will remain deflated. We chose a normally closed valve because it is less of a power drain when we only need it to be open for short periods of time.

- Important Note Make sure that your valve is pressure rated high enough for whatever you are trying to contain (in our case we needed our valve to be pressure rated to 800-900 PSI). Our valve was not rated highly enough, therefore, we required a pressure regulator in order to step down the pressure so that the air would not just overpower our normally closed valve. The large size and weight of our regulator restricted us from creating a more compact and sleek design, because of it, we had no need try and minimize the size of our other components due to the limiting factor of the regulator's (and the CO2 canister's) size.

The way that we directed the voltage running through our solenoid valve was with a MOSFET controlled circuit (a schematic is shown to the right)