Searching for Stability Weekly Log

2/13/16

This week we successfully scaled down our initial project idea for a quadcopter to a more feasible product idea of an Arduino controlled 2-axis gimbal on a bike-mounted platform. As opposed to using an IMU, we decided to use two magnetic rotary encoders to challenge ourselves in the realm of electrical and systems engineering. Additionally, we finalized a project proposal after making some intensive revisions and created a detailed budget.

We have conducted initial research concerning the connection of the rotary magnetic encoders to the Arduino.

2/20/16

We completed a first design rendering for our stabilization platform; it is in the very early stages of development.

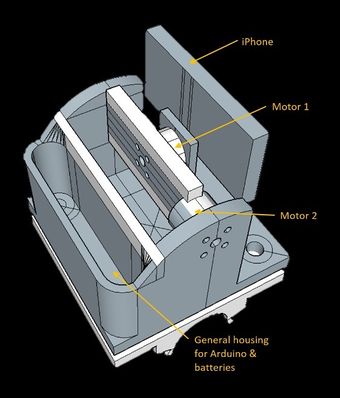

This was the second version we designed later in the week. It illustrates how the iPhone would sit in the gimbal and where our two motors would be located.

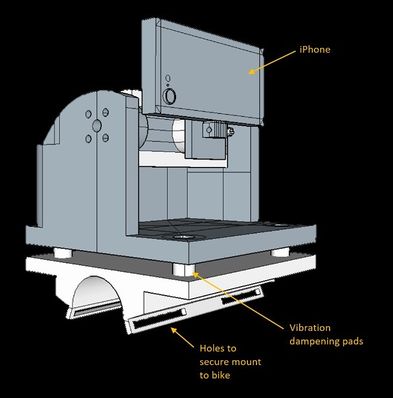

We were concerned that this mounting design would be impractical for a bike-rider as the gimbal would take up the entirety of one handle. However, after some research, we found that the majority of bike mounted devices sit on the handlebar and thus plan to model a revised design after pre-existing handlebar bike mounts. Additionally, we are including more specific compartments within the back slot housing the four 9V batteries and the Arduino to eliminate unnecessary confusion and jumbling of components.

In addition to these designs, we ordered our magnetic rotary encoders and vibration dampening pads and plan to order the batteries and motors once the budget is approved.

2/27/16

Our budget was approved! We ordered two Turnigy brushless gimbal motors and four rechargeable 9V batteries. Our encoders and vibration dampening pads arrived on Wednesday, however we got two extra relay boards while the two rotary encoder shafts were omitted from the shipment. We called the vendor and the missing components were expedited to us and arrived on Saturday.

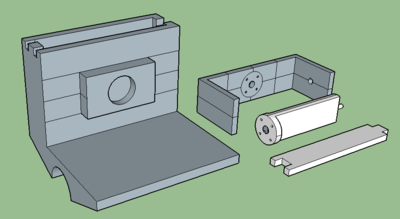

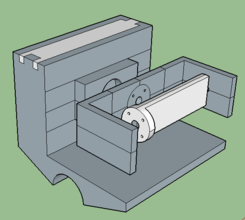

We continued to update the 3D design of our mounting platform and began test printing on Friday. We printed the two basic components that attach directly to the bike handle and tested to make sure the dimensions were correct and that they fit together snuggly. While the first print failed due to the presence of internal faces, we re-printed after fixing the file and the dimensions appeared correct when tested for fit on a bike handle. The first print of the outer support component also failed due internal faces that confused the printer. From this failed print, however, we realized that some of the proportions were off as the Arduino could not fit in its designated compartment. Thus, we altered the design to make the compartment sufficiently tall and added some structural support to the two arms of the outer frame. After printing a miniature version to ensure that there were no more internal edges, we initiated a full-sized print of the outer frame. Below are images of the mounting device with the revised frame structure, the miniature print of the outer frame, and the two basic components for direct mounting on the bike.

With regards to programming the Arduino, progress has been relatively slow as we both are unfamiliar with the coding language. Natalie successfully downloaded the Arduino software (IDE) to her computer and uploaded and ran the "Blink Example". We are working hard to research how to go about writing code that will receive input from the encoders regarding the position of the motors and output corrections to the motor. Additionally, we are in the process of devising test cases so that we can test our code or portions of code without having to have a fully functional mechanical model.