Product: ABAQUS/Standard

Young's modulus = 200 × 103 N/mm2, Poisson's ratio = 0.3, Creep law: ![]() = A

= A![]() , A = 3.125 × 10–14 per hour (

, A = 3.125 × 10–14 per hour (![]() in N/mm2), n = 5.

in N/mm2), n = 5.

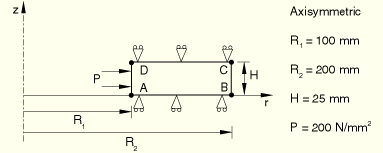

Boundary conditions:

![]() on line AB and

on line AB and ![]() on line CD.

on line CD.

Loading:

Prescribed pressure P = 200 N/mm2 on line AD.

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test 7 from NAFEMS Publication Ref: R0027, “NAFEMS Fundamental Tests of Creep Behaviour,” June 1993.

The results are shown in the following tables. The values enclosed in parentheses are percentage differences with respect to the reference solution. A graphic following each table gives a representation of the different stresses through the thickness of the cylinder.

| ABAQUS results for CAX8R elements | ||

|---|---|---|

| Radius | ||

| (steady state) | (steady state) | |

| 100.0 | –197.95 (–1.02%) | 131.68 (1.00%) |

| 125.0 | –128.03 (–1.11%) | 173.55 (0.49%) |

| 150.0 | –75.416 (–1.21%) | 205.12 (0.27%) |

| 175.0 | –33.708 (–1.84%) | 230.15 (0.16%) |

| 200.0 | 0.499 | 250.67 (0.11%) |

| ABAQUS results for CCL24R elements | ||

|---|---|---|

| Radius | ||

| (steady state) | (steady state) | |

| 100.0 | –197.95 (–1.02%) | 130.38 (1.00%) |

| 125.0 | –128.03 (–1.11%) | 172.70 (0.49%) |

| 150.0 | –75.417 (–1.21%) | 204.12 (0.26%) |

| 175.0 | –33.707 (–1.85%) | 230.15 (0.16%) |

| 200.0 | 0.505 | 250.67 (0.11%) |

The total creep time for this test is 1000 hours. In the case where CAX8R elements have been used, four elements were used to model the cylinder. In the case where CCL24R elements were used, four elements were used in the radial direction and eight elements were used to model the full cylinder in the circumferential direction; that is, a total of 32 elements.