Product: ABAQUS/Standard

Linear elastic, Young's modulus = 250 GPa, Poisson's ratio = 0.25, yield stress = 5 MPa, strain at first yield = 0.25 × 10–4, hardening modulus = 0 or 62.5 GPa.

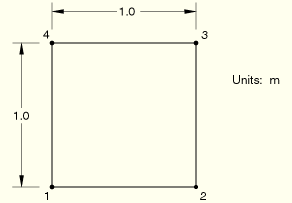

Boundary conditions:

| Step 1: |

| Step 2: |

| Step 3: |

| Step 4: |

| Step 5: |

| Step 6: |

| Step 7: |

| Step 8: all degrees of freedom constrained with zero displacement |

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test NL1 from NAFEMS Publication NNB, Rev. 1, “NAFEMS Non-Linear Benchmarks,” October 1989.

The results are shown in the following table. The values enclosed in parentheses are percentage differences with respect to the reference solution.

| Strain (× 10–4) | Target effective stress (MPa) | |||

|---|---|---|---|---|

| Perfect plasticity | Isotropic hardening | |||

| (H = 0 GPa) | (H = 62.5 GPa) | |||

| 0.25 | 0.0 | 0.0 | 5.000 (0%) | 5.000 (0%) |

| 0.50 | 0.0 | 0.0 | 5.000 (0%) | 5.862 (0%) |

| 0.50 | 0.25 | 0.0 | 5.000 (0%) | 5.482 (0%) |

| 0.50 | 0.50 | 0.0 | 5.000 (0%) | 6.359 (–0.05%) |

| 0.25 | 0.50 | 0.0 | 5.000 (0%) | 6.626 (–0.21%) |

| 0.0 | 0.50 | 0.0 | 5.000 (0%) | 7.297 (–0.34%) |

| 0.0 | 0.25 | 0.0 | 3.824 (–2.4%) | 4.114 (–2.70%) |

| 0.0 | 0.0 | 0.0 | 5.000 (0%) | 5.532 (–2.50%) |

The loading and constraints on the model ensure that the force residuals at the nodes are always zero, regardless of the state of stress in the element. ABAQUS, therefore, does not iterate. The results tabulated above are obtained using direct integration (*STATIC, DIRECT) with 10 increments, as recommended in the test description. More accurate results are obtained if a larger number of increments is specified.