Products: ABAQUS/Standard ABAQUS/CAE

Benefits: The true surface-to-surface formulation for small-sliding contact optimizes stress accuracy for surface pairings with mismatched meshes and accounts for surface thicknesses.

Description: A true surface-to-surface formulation has been added for small-sliding contact in ABAQUS/Standard. In contrast to the existing node-to-surface approach, this new approach does not lead to stress oscillations at a contact interface, even for mismatched meshes. In addition, the new formulation accounts for surface thicknesses and offsets. The node-to-surface approach remains the default, but you are encouraged to use the surface-to-surface approach. In some cases the surface-to-surface approach can result in significantly increased computational cost; see “Surface-to-surface tie constraint formulation,” Section 10.1, for further discussion.

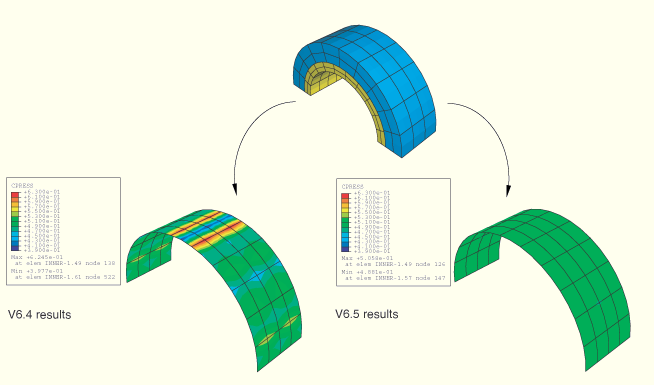

As an example, consider concentric rings with an interference fit modeled with C3D20 hexahedral elements and small-sliding contact. The analytical solution has a uniform contact pressure of 0.493. The surface-to-surface approach significantly reduces the noise in contact pressures compared to the node-to-surface approach. Contour plots of contact pressures predicted with the node-to-surface approach show deviations of up to 27% from the analytical solution; whereas these deviations remain within 3% of the analytical solution with the surface-to-surface approach.

Figure 11–1 Comparison of contact pressures at the contact interface between concentric rings modeled with C3D20 elements.

Interaction module: InteractionCreate: Surface-to-surface contact (Standard): Sliding formulation: Small sliding, Constraint enforcement method: Surface to surface

“Small-sliding contact between stress/displacement elements,” Section 1.6.1

“Small-sliding contact between coupled temperature-displacement surfaces,” Section 1.6.2

“Small-sliding contact between coupled pore pressure-displacement elements,” Section 1.6.3

“Automatic element conversion for surface contact,” Section 1.6.14

“Contact with initial overclosure of curved surfaces,” Section 1.6.15

“Small-sliding contact with specified clearance or overclosure values,” Section 1.6.16

“Adjusting contact surface normals at symmetry planes,” Section 1.6.20