Product: ABAQUS/Standard

Elastic and elastic-plastic cases of a beam under pure bending are tested. Nonlinear multipoint constraints and section ovalization are also tested.

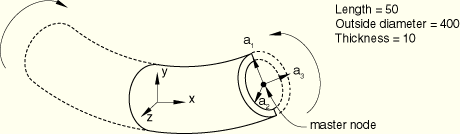

Model:A quarter model is used because of symmetry.

Material:Young's modulus = 1.93 × 105, Poisson's ratio = 0.26, plastic (isotropic hardening).

Boundary conditions:

Symmetry on plane ![]() = 0 (

= 0 (![]() ; symmetry on plane

; symmetry on plane ![]() = 0 (

= 0 (![]() ; symmetry on rotated plane: i) Shell nodes must remain in rotated plane (Nonlinear MPC). ii) The

; symmetry on rotated plane: i) Shell nodes must remain in rotated plane (Nonlinear MPC). ii) The ![]() -rotation of shell nodes in the rotated plane must be the same as the master node (Linear MPC). iii) The component of rotation about the local

-rotation of shell nodes in the rotated plane must be the same as the master node (Linear MPC). iii) The component of rotation about the local ![]() -axis must be zero (Nonlinear MPC). The master node is constrained to move on the

-axis must be zero (Nonlinear MPC). The master node is constrained to move on the ![]() -axis only.

-axis only.

Loading:

![]() -rotation applied to pipe end (

-rotation applied to pipe end (![]() = 0.004).

= 0.004).

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test 3DNLG-8 from NAFEMS Publication R0024 “A Review of Benchmark Problems for Geometric Non-linear Behaviour of 3-D Beams and Shells (SUMMARY).”

The published results of this problem were obtained with ABAQUS. Thus, a comparison of ABAQUS and NAFEMS results is not an independent verification of ABAQUS. The NAFEMS study includes results from other sources for comparison that may provide a basis for verification of this problem.

In the following table, the end moments for the elastic and elastic-plastic cases are reported at three rotation values of the master node. All the meshes have the same nodal spacing.

| Element | ||||||

|---|---|---|---|---|---|---|

| Moment × 10–9 | Moment × 10–9 | Moment × 10–9 | ||||

| Elastic | Plastic | Elastic | Plastic | Elastic | Plastic | |

| S3/S3R | 2.056 | 0.5146 | 3.488 | 0.5402 | 3.704 | 0.5066 |

| S4 | 2.032 | 0.5088 | 3.452 | 0.5350 | 3.676 | 0.5042 |

| S4R | 2.020 | 0.5080 | 3.436 | 0.5332 | 3.664 | 0.5024 |

| S4R5 | 2.018 | 0.5078 | 3.420 | 0.5334 | 3.578 | 0.5008 |

| S8R | 2.054 | 0.5116 | 3.448 | 0.5380 | 3.568 | 0.5024 |

| S8R5 | 2.054 | 0.5118 | 3.452 | 0.5380 | 3.582 | 0.5030 |

| S9R5 | 2.054 | 0.5118 | 3.452 | 0.5380 | 3.582 | 0.5030 |

| STRI3 | 2.056 | 0.5144 | 3.474 | 0.5390 | 3.662 | 0.5036 |

| STRI65 | 2.054 | 0.5122 | 3.452 | 0.5388 | 3.592 | 0.5046 |

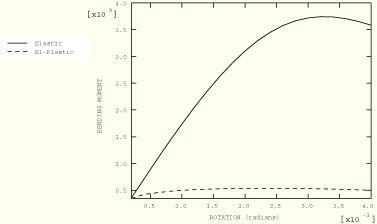

Essentially identical moment-rotation curves (at the master node) are obtained for all test cases. The response predicted using S8R5 elements is shown below.

S3/S3R elements.

User subroutine MPC used in n3g8xf31.inp.

S4 elements.

User subroutine MPC used in n3g8xe41.inp.

S4R elements.

User subroutine MPC used in n3g8xf41.inp.

S4R5 elements.

User subroutine MPC used in n3g8x541.inp.

S8R elements.

User subroutine MPC used in n3g8x681.inp.

S8R5 elements.

User subroutine MPC used in n3g8x581.inp.

S9R5 elements.

User subroutine MPC used in n3g8x591.inp.

STRI3 elements.

User subroutine MPC used in n3g8x631.inp.

STRI65 elements.

User subroutine MPC used in n3g8x561.inp.

S3/S3R elements.

User subroutine MPC used in n3g8xf32.inp.

S4 elements.

User subroutine MPC used in n3g8xe42.inp.

S4R elements.

User subroutine MPC used in n3g8xf42.inp.

S4R5 elements.

User subroutine MPC used in n3g8x542.inp.

S8R elements.

User subroutine MPC used in n3g8x682.inp.

S8R5 elements.

User subroutine MPC used in n3g8x582.inp.

S9R5 elements.

User subroutine MPC used in n3g8x592.inp.

STRI3 elements.

User subroutine MPC used in n3g8x632.inp.

STRI65 elements.

User subroutine MPC used in n3g8x562.inp.