Product: ABAQUS/Standard

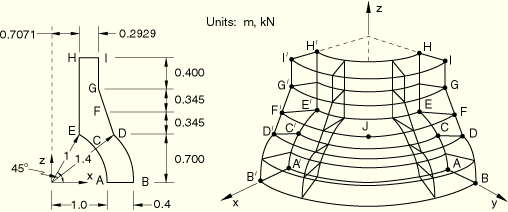

Mesh:

A coarse and a fine mesh are tested.

Material:Linear elastic, Young's modulus = 210 GPa, Poisson's ratio = 0.3, coefficient of thermal expansion = 2.3E4/°C.

Boundary conditions:

![]() 0 on the plane

0 on the plane ![]() 0.

0. ![]() 0 on the plane

0 on the plane ![]() 0.

0. ![]() 0 on the plane

0 on the plane ![]() 0 and the face HIH′I′.

0 and the face HIH′I′.

Loading:

Linear temperature gradient in the radial and axial directions is given by

![]()

This is applied using user subroutine UTEMP.

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test LE11 from NAFEMS Publication TNSB, Rev. 3, “The Standard NAFEMS Benchmarks,” October 1990.

Target solution: Direct stress, ![]() = –105 MPa at point A.

= –105 MPa at point A.

The results are shown in the following table. The values enclosed in parentheses are percentage differences with respect to the reference solution.

C3D20 elements.

User subroutine used in nle11fkc.inp.

C3D20R elements.

User subroutine used in nle11rkc.inp.

C3D20 elements.

User subroutine used in nle11fkf.inp.

C3D20R elements.

User subroutine used in nle11rkf.inp.